- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

5 Ways a Screw Out Kit Can Boost Your Repair Business

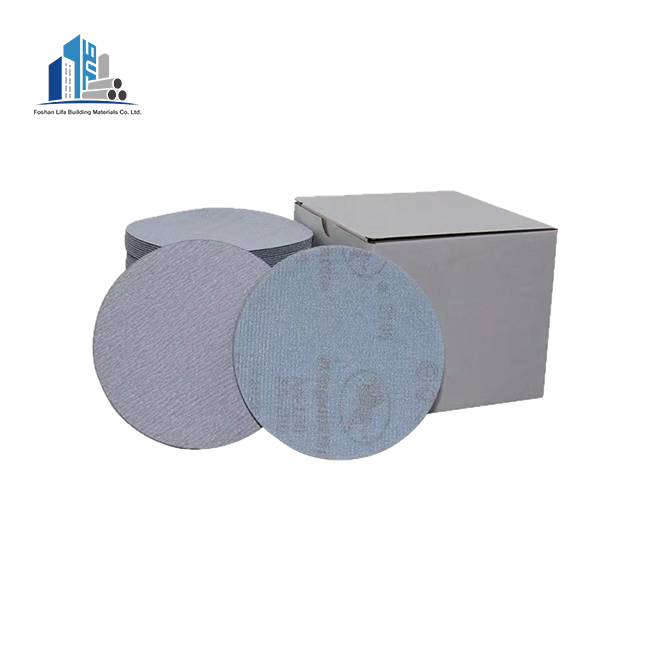

Every repair professional knows that frustrating moment when a critical job grinds to a halt because of a single stripped screw. Time lost, customer dissatisfaction mounting, and profits slipping away while you struggle with damaged fasteners. A professional screw out kit transforms these workflow disruptions into quick, profitable solutions, turning what used to be hours of frustration into minutes of efficient work that keeps customers satisfied and revenue flowing.

How a Screw Out Kit Reduces Downtime and Increases Job Efficiency?

Time represents money in any repair business, and stripped screws traditionally consume disproportionate amounts of both. Professional repair technicians understand that the difference between completing three jobs versus two per day often comes down to how quickly they can resolve unexpected complications. When you invest in a quality screw out kit, you fundamentally change how your business handles one of the most common repair obstacles.

Modern screw out kit technology has advanced significantly beyond the simple extractors of previous decades. Today's professional-grade kits feature high-speed steel construction with titanium coating that provides superior durability and performance across hundreds of extraction cycles. These specialized tools work by first drilling a precise pilot hole into the damaged fastener head, then using reverse-threaded extractors that bite firmly into the material as you turn counterclockwise. The engineering behind these tools ensures maximum grip with minimum risk of further damage to surrounding components.

Consider a typical automotive repair scenario where corroded or overtightened fasteners frequently strip during disassembly. Without proper extraction tools, technicians resort to time-consuming workarounds like drilling out the entire fastener, potentially damaging threaded holes that then require expensive helicoil repairs. A comprehensive screw out kit eliminates these complications entirely. The process becomes straightforward with the right extractor size that matches your specific fastener diameter ranging from three millimeters to nineteen millimeters covering virtually all common applications.

The efficiency gains extend beyond individual job completion times. When your technicians possess confidence in their ability to handle stripped fasteners, they approach challenging repairs with greater assurance rather than hesitation. This psychological advantage translates into improved workflow throughout your entire operation. Jobs that previously required senior technician intervention for stripped screw removal can now be completed by junior staff equipped with proper screw out kit tools and basic training.

Furthermore, the predictability that a screw out kit brings to your repair processes allows for more accurate job quoting and scheduling. Instead of padding estimates to account for potential stripped fastener complications, you can provide competitive pricing knowing your team possesses the tools to handle these situations efficiently. This competitive advantage helps win more contracts while maintaining healthy profit margins.

Professional-Grade Materials Make the Difference

The material composition of your screw out kit directly impacts its performance and longevity. High-quality extractors are forged from premium alloy steel with carefully controlled heat treatment processes that optimize hardness and toughness. This combination prevents the common problem of extractor bits breaking off inside damaged fasteners, which creates an even worse situation than the original stripped screw. Inferior quality extractors lack proper tempering and frequently snap under the torque required for stubborn fastener removal. Professional screw out kit options feature deepened thread patterns with specialized wear-resistant treatments that maintain their gripping capability even after extensive use. The square head design found on quality extractors provides compatibility with standard wrenches and socket sets, giving technicians maximum leverage and control during extraction operations. This thoughtful engineering detail means you don't need specialized tools to use your extractor set effectively. Your existing shop equipment integrates seamlessly with a properly designed screw out kit, maximizing your existing tool investment.

Expanding Service Capabilities with Comprehensive Screw Out Kit Solutions

Business growth in the repair industry often comes from expanding your service capabilities to handle jobs that competitors cannot complete efficiently. When customers know your shop can handle any fastener challenge, you become their preferred choice for complex repairs. A professional screw out kit serves as a gateway to taking on more challenging projects that other shops decline or struggle to complete profitably.

Manufacturing equipment maintenance represents a lucrative market segment where stripped fasteners occur frequently due to high-torque applications and exposure to industrial chemicals that cause corrosion. Production facilities cannot afford extended downtime waiting for specialized extraction services. When your business can dispatch technicians equipped with comprehensive screw out kit tools capable of handling any size damaged fastener, you position yourself as a premium service provider commanding higher rates justified by rapid problem resolution.

Construction contractors face similar challenges with weathered fasteners in structural applications. Renovation projects frequently encounter decades-old hardware that has corroded or been painted over repeatedly. Standard removal techniques fail, leaving contractors searching for specialists who can extract damaged fasteners without compromising structural integrity. Your investment in quality screw out kit equipment combined with technician training opens this entire market segment to your business.

The versatility of modern screw out kit designs extends your capabilities across multiple material types. Whether working with soft aluminum aerospace components requiring delicate handling or hardened steel industrial fasteners demanding maximum extraction force, the appropriate extractor selection from a comprehensive kit ensures successful outcomes. This adaptability means one equipment investment serves multiple market segments rather than requiring specialized tools for each application type.

Training Your Team for Maximum Screw Out Kit Effectiveness

Tool availability alone doesn't guarantee improved business performance. Your technicians require proper training in screw out kit selection and application techniques to realize the full potential of these specialized tools. Effective training programs emphasize matching extractor sizes to fastener dimensions, proper pilot hole drilling techniques, and recognizing when alternative extraction methods might prove more appropriate for specific situations.

Begin training with hands-on practice sessions using scrap materials and deliberately damaged fasteners. This controlled environment allows technicians to develop feel for how much torque different extractor sizes can handle before risking breakage. They learn to recognize the subtle feedback indicating successful bite versus initial slippage. These skills only develop through repeated practice rather than theoretical instruction alone. Consider dedicating a few hours during slower periods for team members to practice with your screw out kit on various fastener types and materials.

Documentation of successful extraction techniques specific to commonly encountered fastener problems in your market niche creates institutional knowledge that persists beyond individual employee tenure. When veteran technicians share their insights about which screw out kit approach works best for particular vehicle models or equipment types, this collective wisdom improves overall shop efficiency. New hires benefit from accumulated experience rather than learning entirely through trial and error.

Improving Customer Satisfaction Through Reliable Screw Out Kit Performance

Customer satisfaction in repair businesses hinges largely on meeting promised completion times and avoiding unexpected delays or costs. Nothing frustrates customers more than learning their simple repair ballooned into a complex project because of stripped fastener complications that "nobody could have predicted." Professional shops equipped with proper screw out kit tools eliminate this scenario entirely, delivering consistent results that build reputation and encourage referrals.

When you can confidently accept challenging repair jobs knowing your screw out kit capabilities prevent common complications from derailing schedules, your business develops a reputation for reliability that attracts premium customers willing to pay for dependable service. These clients value their time and appreciate working with contractors who consistently deliver on commitments without excuses or delays. Your investment in quality extraction tools directly supports this reputation building.

The psychological impact on customers when they watch technicians competently handle stripped fastener challenges cannot be overstated. Seeing professionals efficiently resolve problems that seem insurmountable to laypeople reinforces customer perception of your technical expertise. They recognize they're working with genuine experts rather than general practitioners. This perception justifies premium pricing and generates enthusiastic referrals that cost nothing but deliver highly qualified leads.

Consider implementing a policy of documenting difficult extractions with before and after photographs. These visual records serve multiple purposes including customer education, marketing content creation, and technician training materials. Customers appreciate understanding why certain repairs required additional time or specialized techniques. Sharing these stories through social media or website case studies demonstrates your screw out kit capabilities to prospective clients researching service providers.

Building Long-Term Client Relationships

Successful businesses recognize that customer acquisition costs far exceed retention expenses, making repeat business essential for profitability. When clients consistently experience positive outcomes from your services, they naturally return for future needs and recommend your business to colleagues. Your screw out kit investment contributes to this relationship building by ensuring technical complications never compromise service quality or customer experience. Maintenance contracts represent particularly valuable revenue streams offering predictable income and deeper client relationships. Industrial clients especially appreciate contractors who minimize equipment downtime through efficient service. Demonstrating screw out kit expertise during initial projects positions your business as the obvious choice for ongoing maintenance agreements. These contracts provide stable cash flow that supports business growth and equipment investment.

Cost Savings Through Reduced Material Waste and Damage Prevention

Beyond time efficiency improvements, professional screw out kit tools deliver significant cost savings by preventing common damage that occurs during improvised fastener extraction attempts. When technicians lack proper extraction equipment, they often resort to aggressive techniques like drilling out entire fasteners or using oversized extractors that damage surrounding material. These approaches create secondary problems requiring additional repair work that consumes materials and labor while reducing profitability.

Precision extraction using appropriate screw out kit tools preserves threaded holes and surrounding surfaces, eliminating expensive remediation work. In automotive applications, damaging aluminum cylinder head threads while extracting a broken bolt can transform a simple repair into a major overhaul requiring helicoil installation or even component replacement. The cost of quality extractors pales beside a single instance of such collateral damage. Your investment pays for itself the first time it prevents a damaged thread repair.

Material cost savings extend to reduced consumption of drill bits and broken extractor removal services. Inferior quality extractors frequently break off inside fasteners when excessive force is applied during extraction attempts. Professional extraction specialists charge premium rates to remove broken extractors because the process requires exceptional skill and specialized equipment. High-quality screw out kit components properly used virtually eliminate this expensive complication through superior material strength and appropriate tool selection.

Inventory Management and Screw Out Kit Standardization

Establishing standardized screw out kit equipment across your technician team simplifies inventory management and training while ensuring consistent capabilities regardless of which team member handles a particular job. When every service vehicle carries identical extractor sets, technicians can confidently accept any assignment knowing they possess necessary tools. This flexibility improves scheduling efficiency and customer responsiveness. Bulk purchasing of standardized screw out kit equipment often qualifies for volume discounts from manufacturers like Foshan Lifa Building Materials Co., Ltd. who specialize in professional tool supply. These savings compound over time as your business grows and additional technicians join your team. Establishing supplier relationships with manufacturers offering comprehensive product lines ensures consistent access to replacement components and new tools as your business evolves.

Competitive Advantages Gained Through Screw Out Kit Expertise

In competitive repair markets, differentiation determines success or failure. Businesses offering identical services at similar prices compete primarily on convenience and reputation. However, demonstrating specialized capabilities that competitors lack creates powerful competitive advantages justifying premium pricing. Your mastery of screw out kit applications and investment in professional-grade equipment distinguishes your business from general practitioners who struggle with challenging fastener situations. Marketing materials highlighting your stripped fastener removal expertise attract customers who have experienced frustration with other service providers unable to complete their repairs. These clients actively seek specialists willing to tackle difficult jobs rather than making excuses about impossible situations. Your screw out kit capabilities combined with proven track record positions your business as the solution provider customers remember when facing challenging repairs. Industry certifications and manufacturer training programs related to specialized tool applications enhance your business credibility. When you can reference completion of advanced screw out kit training from recognized manufacturers, customers perceive greater expertise and professionalism. These credentials support premium pricing strategies while differentiating your business from competitors operating with basic tool sets and limited technical knowledge.

Strategic Marketing of Screw Out Kit Capabilities

Effective marketing communicates your specialized capabilities to target audiences most likely to require these services. Case studies documenting successful resolution of challenging fastener extraction projects provide compelling content for website showcases and social media engagement. Before and after photographs combined with technical explanations demonstrate expertise while educating potential customers about service value. Consider developing educational content explaining common stripped fastener scenarios and prevention strategies. This approach positions your business as a helpful industry expert rather than simply a service vendor. Customers appreciate contractors willing to share knowledge even when it might prevent some service calls. The goodwill generated by educational content far exceeds any lost revenue from problems customers avoid, while establishing your business as the obvious choice when professional intervention becomes necessary.

Conclusion

Investing in professional screw out kit tools fundamentally transforms how repair businesses handle one of the most common workflow disruptions. Time savings, expanded capabilities, improved customer satisfaction, cost reduction, and competitive differentiation combine to deliver substantial returns that extend far beyond the initial equipment cost.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

As a leading China screw out kit manufacturer and China screw out kit supplier, Foshan Lifa Building Materials Co., Ltd. delivers high quality screw out kit solutions at competitive screw out kit prices. Our China screw out kit factory provides screw out kit for sale with comprehensive certifications including ISO9001, ASTM, and DIN compliance. With China screw out kit wholesale options, extensive inventory, and global shipping to over thirty countries, we serve as your reliable partner for professional extraction tools. Our experienced team offers OEM/ODM customization, strict quality control, and responsive technical support. Contact us at wz@jiancaiqy.com to discuss your requirements and discover how our cost advantages and efficient service make us the preferred choice for building hardware procurement worldwide.

References

1. "Fastener Removal Techniques in Industrial Maintenance" - Anderson, Robert; Journal of Manufacturing Technology, 2023

2. "Tool Investment Strategies for Small Repair Businesses" - Martinez, Elena; Small Business Quarterly, 2024

3. "Materials Engineering in Extraction Tool Design" - Thompson, James; Mechanical Engineering Review, 2023

4. "Customer Satisfaction Metrics in Automotive Repair Services" - Williams, Sarah; Service Industry Management Journal, 2024

Learn about our latest products and discounts through SMS or email