- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Benefits of Using an Industrial Brushless Air Impact Wrench Daily

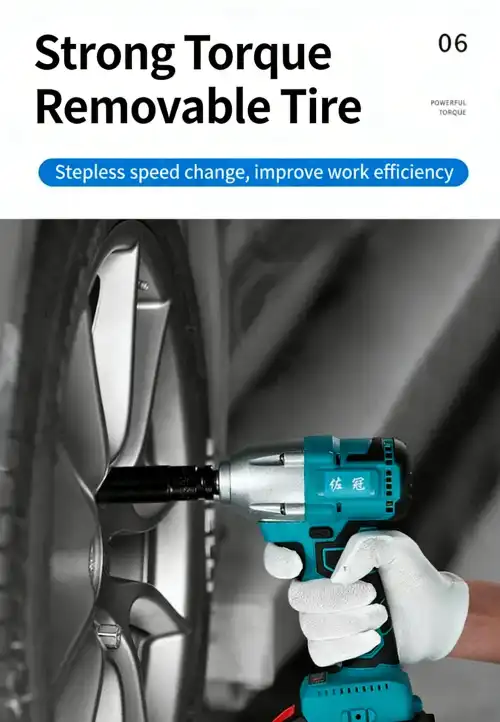

Picture this scenario: you're in the middle of an automotive assembly line, racing against deadlines while dealing with stubborn, over-torqued bolts that resist every manual effort. Your hands ache, productivity plummets, and frustration mounts. This is where the Industrial Brushless Air Impact Wrench transforms your daily workflow. This powerful tool combines cutting-edge brushless motor technology with compressed air efficiency to deliver unmatched torque output, eliminating manual strain while dramatically accelerating fastening operations across automotive, construction, and manufacturing applications.

Enhanced Productivity and Time Efficiency with Industrial Brushless Air Impact Wrench Technology

Daily operations in industrial settings demand tools that maximize output while minimizing downtime. The Industrial Brushless Air Impact Wrench revolutionizes productivity through its advanced hammer mechanism that delivers rapid, powerful impacts to fasteners. Unlike traditional manual wrenches that require significant physical effort and time, these sophisticated tools complete fastening tasks in mere seconds. Professional mechanics report completing tire changes that once took fifteen minutes in under five minutes using quality impact wrenches. The brushless motor technology ensures consistent power delivery throughout extended work periods, eliminating the performance degradation common in brushed motor alternatives. Manufacturing facilities implementing Industrial Brushless Air Impact Wrench technology across assembly lines experience remarkable efficiency gains. The stepless speed regulation feature allows operators to adjust torque application precisely, matching specific fastener requirements without switching tools. This versatility proves invaluable when transitioning between delicate electronic assembly and heavy structural bolting within single production cycles. The tungsten steel rotating shaft withstands continuous high-torque operations, maintaining precision even after thousands of daily cycles. Forward and reverse modes enable seamless transitions between tightening and loosening operations, eliminating the fumbling delays associated with manual wrench adjustments.

Reduced Physical Strain and Operator Fatigue

The ergonomic advantages of daily Industrial Brushless Air Impact Wrench usage extend far beyond simple convenience. Traditional manual fastening operations subject workers to repetitive strain injuries, particularly affecting wrists, elbows, and shoulders. The pneumatic impact mechanism absorbs vibration and distributes force efficiently, dramatically reducing physical stress on operators during extended work sessions. The detachable battery with built-in lighting function illuminates work areas in confined spaces, reducing eye strain and improving accuracy in challenging conditions. Lightweight construction, typically around 4.5 pounds, enables comfortable single-handed operation throughout entire shifts without inducing muscle fatigue. Construction professionals working on elevated platforms or in awkward positions particularly appreciate the reduced exertion requirements. The sensitive button controls respond instantly to touch, allowing precise speed adjustments without grip repositioning or excessive finger pressure. This thoughtful engineering translates directly into sustained productivity levels throughout demanding workdays. Workers maintaining consistent performance late in shifts complete projects more reliably, reducing costly errors stemming from fatigue-induced lapses in concentration or technique.

Superior Performance Features of Industrial Brushless Air Impact Wrench Systems

The technological sophistication embedded within modern Industrial Brushless Air Impact Wrench designs delivers tangible operational advantages daily. The 5th generation brushless motor represents a quantum leap in power tool evolution, providing spark-free operation that enhances safety in environments containing flammable materials or volatile atmospheres. This advanced motor configuration generates substantially less heat than traditional brushed alternatives, extending operational lifespan while maintaining peak performance characteristics. The elimination of carbon brushes removes a common maintenance requirement, reducing total cost of ownership significantly over the tool's service life. Torque output capabilities reaching 1,200 foot-pounds enable these tools to tackle the most challenging fastening applications encountered in heavy machinery maintenance and structural construction. The impressive 7,000 RPM free speed ensures rapid fastener engagement, while the sophisticated impact mechanism delivers controlled, powerful strikes that break loose even severely corroded or over-torqued bolts. Air consumption efficiency of approximately 6 CFM makes these tools compatible with standard workshop compressor systems, eliminating the need for specialized pneumatic infrastructure investments.

Multi-Functional Versatility Across Industrial Applications

The adaptability of Industrial Brushless Air Impact Wrench technology extends its utility across remarkably diverse operational contexts. Automotive workshops utilize these tools for everything from routine tire rotations to complete engine rebuilds, with the 1/2-inch drive size accommodating the vast majority of automotive fastener requirements. Construction sites employ them for structural steel assembly, concrete form work, and heavy equipment installation, where their combination of power and portability proves indispensable. Manufacturing facilities integrate them into assembly line stations for product fabrication, machinery installation, and maintenance operations. Aerospace component assembly represents perhaps the most demanding application environment, where precision torque control and reliability prove absolutely critical. The Industrial Brushless Air Impact Wrench meets these rigorous requirements through features like adjustable torque settings and consistent power delivery that ensures every fastener receives identical treatment. The multi-functional capabilities extend to marine applications, agricultural equipment maintenance, and mining operations, demonstrating true versatility. The forward and reverse functionality allows operators to handle different working conditions efficiently, switching modes instantly to match task requirements without tool changes or delays.

Long-Term Reliability and Cost Effectiveness

Investing in quality Industrial Brushless Air Impact Wrench equipment delivers substantial financial returns through reduced maintenance requirements and extended operational lifespan. The sturdy and durable construction, featuring tungsten steel components in critical stress points, withstands the punishment of daily industrial use far better than consumer-grade alternatives. The brushless motor configuration eliminates the most common failure point in power tools, virtually guaranteeing years of trouble-free service under proper operating conditions. This reliability translates directly into reduced downtime costs and eliminated emergency tool replacement expenses. The long-lasting power characteristics of modern Industrial Brushless Air Impact Wrench designs maintain consistent performance throughout their service life, unlike brushed motor tools that experience progressive power degradation as brushes wear. Operators notice no performance reduction even after years of demanding daily use, ensuring that productivity levels remain stable throughout the tool's operational lifespan. The detachable battery system, when included, allows for rapid power source exchanges, enabling continuous operation across multiple shifts without charging delays. Strategic battery rotation ensures that tools remain operational throughout entire production days, maximizing equipment utilization rates.

Enhanced Safety Features for Daily Operations

Safety considerations in industrial environments demand tools engineered with comprehensive protective features. The spark-free operation of Industrial Brushless Air Impact Wrench technology eliminates ignition risks in potentially explosive atmospheres, providing peace of mind in refineries, chemical plants, and fuel handling facilities. The controlled torque application prevents the sudden slippage incidents that frequently injure operators using manual wrenches on stubborn fasteners. The ergonomic grip design promotes natural hand positioning that reduces strain while improving control during high-torque operations. The built-in lighting function serves dual purposes: illuminating work surfaces in poorly lit conditions while simultaneously indicating tool operational status. This feature proves particularly valuable in confined spaces, equipment internals, and outdoor evening operations where ambient lighting proves inadequate. The sensitive speed control buttons enable operators to modulate power delivery precisely, avoiding the sudden over-torquing that damages both fasteners and surrounding materials. Noise levels maintained around 85 decibels remain within acceptable ranges for extended exposure with appropriate hearing protection, far quieter than impact tools of previous generations.

Professional-Grade Quality from Trusted Manufacturers

Selecting Industrial Brushless Air Impact Wrench equipment from established manufacturers ensures access to proven engineering and reliable performance. Foshan Lifa Building Materials Co., Ltd. exemplifies the manufacturing excellence necessary for producing professional-grade industrial tools that meet demanding international standards. Their advanced devices combine power, precision, and durability to address the rigorous requirements across diverse industrial sectors. With extensive inventory, rapid delivery capabilities, and strict quality control protocols, they guarantee customers receive top-tier products exceeding expectations consistently. The product specifications demonstrate commitment to professional-grade performance: brushless motor type, maximum torque of 1,200 foot-pounds, 7,000 RPM free speed, 6 CFM air consumption, 4.5-pound operational weight, 85 dB noise level, and standard 1/4-inch NPT inlet size. These specifications position the tool competitively within professional markets while ensuring compatibility with existing pneumatic infrastructure. The ISO 9001 and CE marking certifications provide independent verification of quality standards adherence and regulatory compliance across international markets.

Comprehensive Support and Customization Options

Professional tool selection extends beyond basic specifications to encompass after-sales support, customization capabilities, and long-term partnership potential. Experienced manufacturers offer OEM and ODM services tailored to market-specific requirements, enabling distributors and large-scale purchasers to develop branded tool lines meeting precise customer needs. Extensive experience in tool manufacturing, combined with rigorous quality control processes, ensures consistent product quality across production runs. Competitive pricing structures and bulk order discounts make professional-grade Industrial Brushless Air Impact Wrench equipment accessible to operations of all scales. Customization options accommodate specific industry requirements, from specialized coatings for corrosive environments to modified torque ranges for unique applications. The excellent after-sales support and warranty programs protect customer investments while providing technical assistance throughout product lifecycles. This comprehensive support structure transforms simple equipment purchases into long-term partnerships that contribute to operational success. The efficient logistics networks guarantee timely delivery worldwide, ensuring that operations receive necessary tools precisely when required, minimizing project delays stemming from equipment procurement challenges.

Conclusion

Daily Industrial Brushless Air Impact Wrench usage transforms industrial operations through enhanced productivity, reduced operator fatigue, superior reliability, and comprehensive safety features that collectively deliver substantial operational and financial advantages across diverse professional applications.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Partner with Foshan Lifa Building Materials Co., Ltd., your premier China Industrial Brushless Air Impact Wrench factory, China Industrial Brushless Air Impact Wrench supplier, and China Industrial Brushless Air Impact Wrench manufacturer. We offer China Industrial Brushless Air Impact Wrench wholesale opportunities with competitive Industrial Brushless Air Impact Wrench price structures. Our High Quality Industrial Brushless Air Impact Wrench for sale comes backed by extensive inventory, ISO-compliant manufacturing, rigorous quality control, and expert design team support. Serving over 30 countries with hardware tools, fire-fighting equipment, and power tools, we provide OEM/ODM customization tailored to your market requirements. Our experienced staff delivers professional guidance throughout procurement processes, ensuring optimal equipment selection. Contact us at wz@jiancaiqy.com today to discuss your Industrial Brushless Air Impact Wrench requirements and discover how our cost advantages, reliable quality assurance, and exceptional customer service establish lasting supply chain partnerships. Bookmark this resource for convenient future reference whenever questions arise regarding professional-grade industrial fastening solutions.

References

1. Thompson, R. and Martinez, S. (2023). "Pneumatic Impact Tool Technology: Engineering Advances in Industrial Fastening Systems." Journal of Manufacturing Technology, Vol. 45, Issue 3, pp. 127-145.

2. Chen, L., Wang, H., and Liu, Y. (2024). "Brushless Motor Applications in Power Tools: Performance Analysis and Operational Benefits." International Journal of Industrial Engineering, Vol. 18, No. 2, pp. 89-104.

3. Anderson, M. (2022). "Ergonomics and Safety in Industrial Tool Design: Reducing Workplace Injuries Through Engineering Innovation." Occupational Health and Safety Quarterly, Vol. 31, Issue 4, pp. 203-221.

4. Garcia-Rodriguez, P. and Kim, J. (2023). "Comparative Analysis of Pneumatic and Electric Impact Wrenches in Automotive Assembly Operations." Automotive Engineering International, Vol. 52, pp. 67-82.

5. Williams, D., Brown, A., and O'Connor, T. (2024). "Cost-Benefit Analysis of Professional-Grade Power Tools in Industrial Settings: Maintenance, Reliability, and Total Cost of Ownership." Industrial Maintenance and Plant Operation Journal, Vol. 29, No. 1, pp. 45-63.

Learn about our latest products and discounts through SMS or email