- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Electric Grouting Machine Price Guide & Buying Checklist

Every contractor faces the same frustrating scenario when water seeps through foundation cracks or tunnel walls fail structural integrity tests. Choosing the wrong electric grouting machine means wasted budget, project delays, and compromised waterproofing results. This comprehensive guide delivers transparent pricing insights, technical specifications, and a proven buying checklist to help construction professionals select high-performance electric grouting machine equipment that matches project requirements while maximizing return on investment across commercial, residential, and infrastructure applications worldwide.

Understanding Electric Grouting Machine Technology and Applications

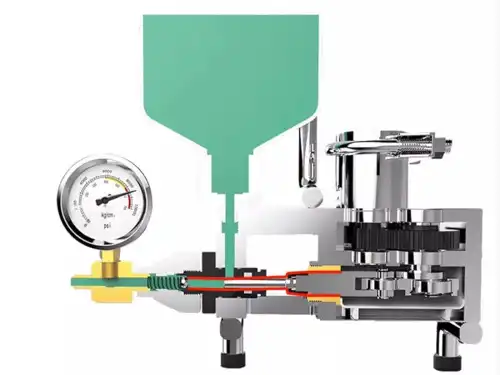

Modern construction projects demand reliable solutions for crack repair, waterproofing, and structural reinforcement. The electric grouting machine has become essential equipment for contractors working on buildings, tunnels, bridges, and underground infrastructure. These specialized pumps inject low-viscosity materials such as water-soluble polyurethane, oil-soluble polyurethane, epoxy resins, and acrylic esters into cracks, expansion joints, and construction joints to prevent water infiltration and restore structural integrity. Unlike manual pumps that require constant physical effort and deliver inconsistent pressure, electric grouting machines provide continuous high-pressure output ranging from 6 MPa to 18000 PSI depending on the model. This automated pressure control ensures uniform material distribution throughout the injection zone, creating permanent waterproof barriers that withstand hydrostatic pressure from groundwater or surface water sources. Professional-grade electric grouting machine models feature stainless steel alloy pump cores that resist corrosion from chemical grouting materials while maintaining precision sealing over thousands of injection cycles. The ABS plastic barrels resist chemical degradation and remain lightweight for easy transport between job sites. Advanced designs incorporate adjustable pressure regulators, allowing operators to customize injection pressure based on crack width, material viscosity, and substrate density. The compact dimensions and ergonomic handles make these units suitable for confined spaces such as basement waterproofing, parking garage repairs, and tunnel maintenance where larger equipment cannot operate effectively.

Key Components That Define Performance Quality

The pump core represents the heart of every electric grouting machine, directly impacting reliability and service life. Premium manufacturers specify wear-resistant alloy pumps machined to tolerances under 0.01mm, ensuring consistent flow rates and preventing material leakage during high-pressure injection operations. When maximum operating pressure reaches 50 MPa, inferior pump components experience deformation that compromises sealing and reduces injection precision. Quality electric grouting machine units maintain structural integrity at peak pressure levels, protecting operators from equipment failure and ensuring consistent material placement throughout the waterproofing process. Power specifications determine operational efficiency across different project scales. Entry-level models typically feature 1100W motors operating at speeds up to 2800 revolutions per minute, delivering flow rates around 0.74 liters per minute suitable for residential crack repair and small commercial projects. Industrial applications requiring higher throughput benefit from 4kW motors that achieve 60 liters per minute flow rates, substantially reducing injection time on large-scale infrastructure projects such as dam construction, tunnel sealing, and bridge foundation reinforcement. The electrical configuration should match local power infrastructure, with most electric grouting machine models offering 110V/220V compatibility and 50Hz or 60Hz operation to serve international markets.

Material Compatibility and Application Versatility

Professional contractors rely on electric grouting machine equipment for diverse waterproofing scenarios because these pumps handle multiple low-viscosity chemical formulations. Water-soluble polyurethane formulations expand upon contact with moisture, making them ideal for active water leaks in basement walls, elevator pits, and underground parking structures. The expanding foam fills void spaces behind concrete surfaces while creating flexible waterproof membranes that accommodate minor structural movement without cracking. Oil-soluble polyurethane materials provide superior adhesion to dry substrates and resist chemical degradation from petroleum products, making them preferred choices for industrial floor joints, containment areas, and highway expansion joints. Epoxy resin injections deliver maximum structural bonding strength for load-bearing crack repairs in concrete beams, columns, and foundation walls. The two-component epoxy systems cure to rock-hard consistency, effectively welding cracked concrete sections together while preventing further crack propagation under stress loads. Acrylic ester formulations offer rapid curing times and excellent UV resistance for exterior applications such as parking deck repairs, plaza waterproofing, and roof penetration sealing. Modern electric grouting machine designs accommodate these varied material viscosities through adjustable pressure controls and specialized injection nozzles that optimize flow characteristics for each chemical type.

Electric Grouting Machine Price Analysis and Budget Planning

Understanding pricing structures helps construction companies allocate equipment budgets effectively while avoiding low-quality machines that compromise project outcomes. Current market analysis reveals that entry-level electric grouting machine models start around two thousand dollars for basic residential applications, while professional-grade units range from four thousand to eight thousand dollars depending on specifications and included accessories. Industrial-capacity systems with automated controls and high-flow pumps command prices between ten thousand and fifteen thousand dollars, justified by their ability to handle large-scale commercial projects and continuous-duty operation cycles. Price variations reflect significant differences in component quality, performance capabilities, and manufacturer support services. Budget-priced electric grouting machine units often utilize plastic pump components that wear rapidly when injecting abrasive materials, leading to frequent replacement costs that exceed initial savings. Mid-range professional models incorporate stainless steel pump assemblies, precision pressure gauges, and reinforced hoses rated for sustained high-pressure operation. Premium industrial systems add programmable controls, automatic pressure compensation, digital flow monitoring, and emergency shutoff features that enhance operator safety while ensuring consistent injection quality across multiple work crews.

Cost Factors Beyond Initial Purchase Price

Smart procurement decisions account for total ownership costs rather than focusing solely on purchase price. Warranty coverage significantly impacts long-term value, with reputable manufacturers offering one to two years protection against defects in materials and workmanship. Extended warranty options provide additional peace of mind for contractors running multiple shifts or operating in harsh environmental conditions. Replacement parts availability directly affects equipment downtime costs, making established manufacturers with comprehensive spare parts inventories more economical than unknown brands with limited support infrastructure. Shipping expenses add substantially to international purchases, particularly for heavy industrial electric grouting machine models weighing over one hundred kilograms. Domestic suppliers offer faster delivery schedules and reduced freight costs compared to direct imports, though overseas manufacturers may provide better baseline pricing. Smart buyers request detailed freight quotations including insurance coverage, customs clearance fees, and door-to-door delivery to accurately compare total acquisition costs. Volume purchases often qualify for significant discounts, with manufacturers offering price reductions ranging from fifteen to thirty percent for orders of five or more units.

Evaluating Return on Investment for Different Project Types

Residential contractors performing occasional foundation repairs may find entry-level electric grouting machine models sufficient for their needs, with payback periods of six to twelve months when compared to manual pump labor costs. Commercial waterproofing specialists benefit from mid-range professional units that offer faster injection speeds and greater reliability, typically recovering equipment costs within three to six months through increased productivity and reduced callback rates. Infrastructure contractors working on tunnels, dams, and bridges require industrial-grade systems capable of continuous operation, where the higher initial investment delivers returns through project completion bonuses and the ability to bid on larger contracts. Rental versus purchase analysis depends on project frequency and duration. Contractors with consistent monthly grouting work achieve better economics through equipment ownership, avoiding daily rental fees that accumulate rapidly. Occasional users might prefer renting electric grouting machine equipment for specific projects, though rental availability varies by geographic region and equipment availability during peak construction seasons. Financing options from manufacturers or equipment dealers allow contractors to acquire professional equipment while preserving working capital for material purchases and payroll obligations.

Essential Buying Checklist for Electric Grouting Machine Selection

Successful equipment purchases start with comprehensive evaluation of technical specifications aligned with actual project requirements. The maximum operating pressure specification determines suitability for different crack widths and injection depths. Shallow surface cracks under five millimeters wide typically require pressures between 3 to 6 MPa, while deep structural cracks exceeding ten millimeters demand injection pressures up to 15 MPa to ensure complete material penetration through the full crack depth. Review manufacturer specifications carefully, noting that advertised maximum pressure often exceeds the recommended continuous operating pressure for extended equipment life. Flow rate capacity directly impacts project completion timelines and labor efficiency. Residential applications involving limited crack length benefit from compact electric grouting machine models delivering 0.5 to 2 liters per minute, sufficient for typical basement waterproofing projects. Commercial building repairs with extensive crack networks require flow rates between 5 to 15 liters per minute to complete injections before material begins curing in application hoses. Large infrastructure projects benefit from industrial pumps achieving 30 to 60 liters per minute throughput, enabling rapid injection of long tunnel joints or dam foundation treatments where material setup time constrains injection windows.

Motor Power and Electrical Requirements Assessment

Motor specifications must match both project demands and available power infrastructure at job sites. Residential electric grouting machine models typically feature 1 to 1.5 kilowatt motors adequate for intermittent operation and standard electrical circuits. Commercial applications benefit from 2 to 4 kilowatt motors that provide consistent pressure throughout extended injection cycles without thermal overload protection trips. Industrial systems may require 5 to 10 kilowatt motors supplied by three-phase electrical service, necessitating coordination with site electrical contractors and temporary power distribution equipment. Voltage compatibility prevents operational delays and additional transformer expenses. International contractors should verify whether electric grouting machine models offer dual voltage capability (110V/220V) or require dedicated units for different regional electrical standards. Frequency specifications matter for motor speed accuracy, with 50Hz and 60Hz versions optimized for their respective electrical systems. Incorrect frequency operation causes motor overheating, reduced pump efficiency, and premature component wear that voids manufacturer warranties.

Portability and Ergonomic Design Considerations

Job site accessibility influences equipment selection, particularly for retrofit and repair applications. Compact electric grouting machine designs weighing under twenty kilograms enable single-person transport up stairwells, through narrow doorways, and into mechanical rooms or utility tunnels where larger equipment cannot access. Integrated carrying handles positioned for balanced weight distribution reduce operator fatigue during movement between injection locations. Equipment stored in protective carrying cases survives rough handling and prevents component damage during vehicle transport. Hose length and flexibility determine working radius without repositioning the pump unit. Standard configurations include five to ten meter hoses suitable for concentrated injection areas, while large project setups benefit from twenty to thirty meter hoses that minimize pump relocation frequency. Metal-reinforced hose construction resists burst failures at maximum operating pressures, providing critical safety protection compared to plastic hoses that fail catastrophically under stress. Quick-disconnect fittings enable rapid hose changes when switching between different injection materials or when transitioning between interior and exterior applications.

Maintenance Requirements and Service Accessibility

Long-term reliability depends on maintenance simplicity and parts availability. Premium electric grouting machine designs feature tool-free disassembly for pump core cleaning after each use, preventing material hardening that causes permanent damage to sealing surfaces. Manufacturers providing detailed maintenance videos and illustrated service manuals empower contractors to perform routine maintenance without specialized training or factory service calls. Readily available wear parts such as seals, gaskets, and check valves enable quick repairs that minimize equipment downtime between projects. Chemical compatibility determines appropriate cleaning procedures following each injection session. Polyurethane materials require flushing with acetone or xylene solvents before curing occurs inside pump chambers and hoses. Epoxy systems demand immediate cleaning with specialized solvents matched to the resin formulation, with hardening times ranging from eight to twenty minutes depending on temperature conditions and catalyst ratios. Electric grouting machine operators must establish cleaning protocols that prevent material buildup while protecting pump components from solvent damage during repeated cleaning cycles.

Supplier Selection and Quality Assurance Standards

Choosing reputable manufacturers and distributors ensures product quality, technical support, and warranty protection. Established companies with ISO9001 certification demonstrate commitment to consistent manufacturing processes and quality management systems. International standards compliance including ASTM specifications and DIN requirements indicates that electric grouting machine products meet rigorous testing protocols for pressure safety, material compatibility, and electrical safety standards recognized across global markets.Factory audits and third-party certifications provide additional confidence in manufacturing capabilities. Suppliers with documented quality control procedures, incoming material inspection protocols, and finished product testing regimens deliver more consistent equipment performance compared to manufacturers lacking formal quality systems. Request specification sheets detailing pump materials, pressure testing results, and electrical safety certifications to verify that marketing claims align with actual product capabilities.

OEM and ODM Customization Capabilities

Large contractors and equipment distributors benefit from manufacturers offering original equipment manufacturer services that enable private labeling and custom specifications. OEM partnerships allow companies to offer branded electric grouting machine equipment tailored to specific market segments or specialized applications not addressed by standard product lines. Minimum order quantities for OEM programs typically start at fifty to one hundred units, requiring significant volume commitments but delivering competitive advantages through exclusive product features. Original design manufacturer services enable development of completely custom electric grouting machine solutions incorporating unique pressure ranges, specialized pump materials, or integrated control systems. ODM projects require substantial engineering investment and longer development timelines, typically spanning six to twelve months from initial concept to production readiness. These services prove valuable for contractors targeting niche markets such as mining applications, marine construction, or specialized industrial maintenance where standard equipment lacks necessary capabilities.

Evaluating Manufacturer Support Infrastructure

Technical support quality significantly impacts equipment uptime and operator productivity. Manufacturers providing detailed product documentation, operation videos, and troubleshooting guides empower contractors to resolve common issues without factory intervention. Responsive customer service teams offering email and phone support during business hours demonstrate commitment to customer success beyond initial equipment sales. Some premium manufacturers provide video consultation services where experienced technicians diagnose problems remotely and guide operators through repair procedures. Spare parts availability through regional distributors eliminates lengthy shipping delays when components require replacement. Manufacturers maintaining inventory in multiple countries offer faster parts delivery compared to suppliers shipping exclusively from overseas factories. Comprehensive parts catalogs with exploded diagrams and part numbers simplify ordering processes and ensure contractors receive correct components. Transparent pricing for replacement parts prevents surprise expenses and enables accurate maintenance budget forecasting.

Conclusion

Investing in the right electric grouting machine transforms waterproofing efficiency and project profitability through proper equipment matching, transparent pricing analysis, and thorough supplier vetting procedures.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Foshan Lifa Building Materials Co., Ltd. stands as your trusted China electric grouting machine factory, China electric grouting machine supplier, and China electric grouting machine manufacturer offering China electric grouting machine wholesale solutions. Our High Quality electric grouting machine for sale delivers exceptional value through competitive electric grouting machine price structures backed by ISO9001, ASTM, and DIN certifications. Operating from China's Pearl River Delta economic hub, we serve over thirty countries with comprehensive building hardware solutions including fire-fighting electromechanical equipment, bathroom plumbing systems, and decorative materials through our expert team specializing in international quality certification and global supply chain management.

Our mature research and development team, GMP-certified factory, extensive inventory, and complete certifications provide cost advantages supporting flexible OEM customization and rapid delivery schedules. We implement strict full-process quality control from raw materials through finished products, ensuring excellent consistency and robust large-scale supply capabilities. Our in-house design team creates custom solutions while experienced staff delivers professional communication and exceptional customer service. Whether you need immediate shipment from our extensive inventory or tailored specifications through OEM support, our competitive pricing and rigorous quality standards make us your ideal supply chain partner. Contact us at wz@jiancaiqy.com to discuss your electric grouting machine requirements and discover how our "Ingenious Manufacturing, Global Sharing" philosophy delivers superior products and services for your construction projects.

References

1. "Guide to Grouting Equipment Selection and Specifications" - Construction Equipment Magazine Editorial Board - Published in Construction Equipment Professional Standards Manual

2. "High-Pressure Injection Technology for Concrete Repair" - American Concrete Institute Committee 546 - ACI Technical Document Series on Concrete Repair

3. "Waterproofing Systems and Materials Handbook" - International Concrete Repair Institute - ICRI Guidelines for Material Selection and Application

4. "Construction Machinery Safety and Performance Standards" - Occupational Safety and Health Administration - OSHA Technical Manual for Construction Equipment

5. "Chemical Grouting Materials and Applications" - National Association of Corrosion Engineers - NACE International Publication on Protective Coatings and Sealants

Learn about our latest products and discounts through SMS or email