- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Choose the Best Screw Out Kit for Your Workshop?

Have you ever been deep into a critical repair project only to have a stripped screw bring everything to a screeching halt? Picture this: you're rushing to meet a deadline, your drill slips, and suddenly that stubborn fastener becomes an immovable obstacle. This frustrating scenario is exactly why selecting the right screw out kit for your workshop isn't just a convenience—it's essential for maintaining productivity and preventing costly project delays. A quality screw out kit transforms what could be hours of frustration into minutes of efficient problem-solving, making it one of the most valuable additions to any professional or home workshop toolkit.

Choosing the best screw out kit requires understanding your specific needs, the materials you work with, and the types of fastener damage you encounter most frequently. Whether you're an automotive technician dealing with rusted bolts, a contractor facing corroded construction fasteners, or a DIY enthusiast maintaining household equipment, the right extractor set can mean the difference between completing a job successfully and causing further damage to expensive components. This comprehensive guide will walk you through every consideration necessary to select a screw out kit that delivers reliable performance when you need it most.

Understanding Screw Out Kit Fundamentals and Why They Matter

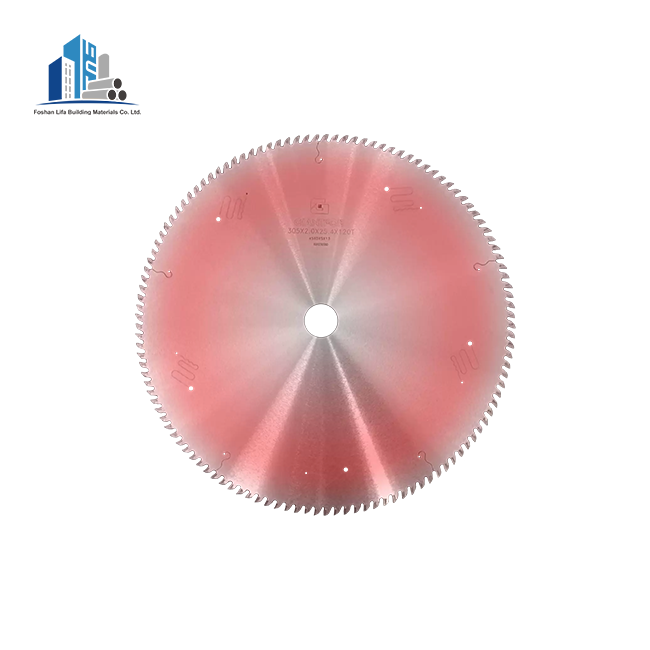

Before investing in a screw out kit, it's crucial to understand exactly what these tools are and how they function in real-world applications. A screw out kit, also known as a screw extractor set or easy-out kit, is a specialized collection of hardened steel tools designed specifically to remove damaged, stripped, or broken fasteners that conventional tools cannot grip. These extractors work on a simple yet ingenious principle: they feature reverse-threaded spiral flutes that bite into a pre-drilled pilot hole in the damaged fastener, allowing you to turn the extractor counterclockwise and extract the screw simultaneously.

The importance of having a quality screw out kit in your workshop cannot be overstated, particularly if you regularly work on automotive repairs, machinery maintenance, or construction projects where fastener damage is common. Unlike standard drill bits or screwdrivers, screw extractors are manufactured from extremely hard materials such as high-speed steel or carbon steel, often with specialized coatings like titanium nitride that enhance durability and reduce friction during extraction. This hardness is essential because the extractor must be significantly harder than the damaged fastener material to effectively grip and remove it without breaking.

Professional workshops and serious DIY enthusiasts rely on screw out kits because they solve problems that would otherwise require drilling out entire fasteners and re-tapping threads—a time-consuming and potentially damaging process. When you understand that a single broken extractor bit can cost more in lost time and potential damage than purchasing a quality kit from the start, the value proposition becomes clear. Modern screw out kit designs incorporate features like square heads for wrench compatibility, deepened thread treatments for enhanced wear resistance, and graduated sizing that matches common fastener dimensions, making them indispensable tools for anyone who regularly works with threaded fasteners.

Types of Screw Extractors and Their Specific Applications

Understanding the different types of extractors included in comprehensive screw out kit sets helps you select the right tool for each specific situation you encounter. Spiral flute extractors represent the most common type found in standard kits, featuring a tapered design with reverse-threaded spiral grooves that bite into the pilot hole as you turn them counterclockwise. These work exceptionally well for removing broken bolts, studs, and screws where the head has completely sheared off, though they require careful centering to avoid damaging surrounding threads.

Straight flute extractors offer an alternative design that some professionals prefer for larger fasteners or situations where the broken screw sits flush or below the surface. Unlike spiral designs, straight flute screw out kit components provide more aggressive bite characteristics, making them ideal for extremely stubborn or corroded fasteners that resist conventional extraction methods. However, these require more torque and careful application to prevent extractor breakage, which can create an even more challenging situation than the original stripped screw.

Multi-spline or hex-head extractors represent a newer innovation in screw out kit technology, designed to grip the external surfaces of rounded-off bolt heads and nuts rather than requiring a pilot hole. These tools feature specially engineered interior surfaces with multiple gripping points that dig into damaged fastener heads when turned with an impact driver or wrench. For professional mechanics and contractors, multi-spline extractors in a comprehensive screw out kit provide the fastest solution for rounded fasteners that still have accessible heads, significantly reducing job completion time compared to traditional drilling and extraction methods.

Essential Specifications to Consider When Selecting Your Screw Out Kit

The material composition and hardness rating of your screw out kit components directly impact their effectiveness and longevity in challenging extraction situations. Premium extractor sets utilize high-speed steel alloy construction with Rockwell hardness ratings between 62-65 HRC, ensuring they remain harder than most common fastener materials including hardened bolts and case-hardened screws. Look for kits that explicitly state their material specifications—vague descriptions like "hardened steel" without specific ratings often indicate lower-quality tools that may fail during critical extractions.

Size range and piece count represent another crucial specification when evaluating different screw out kit options for your workshop needs. Professional-grade sets typically include anywhere from 10 to 35 pieces, covering fastener sizes from tiny precision screws as small as 3mm up to heavy-duty bolts measuring 19mm or larger. The optimal kit for your application depends on the size range of fasteners you regularly encounter—automotive mechanics might prioritize larger sizes for suspension and engine work, while electronics repair specialists need extremely small precision extractors. Quality manufacturers like those producing extractors from high-quality alloy steel with good toughness, high torque capability, and greater durability ensure their screw out kit offerings include clear size markings and organized storage cases that prevent confusion during urgent repairs.

Compatibility features significantly enhance the practical utility of any screw out kit you select for your workshop. Modern professional-grade extractors often incorporate square head designs that work seamlessly with standard adjustable wrenches, making them compatible with the tools you already own rather than requiring specialized equipment. Some advanced screw out kit sets include integrated drill bit collections sized to match each extractor perfectly, eliminating guesswork when creating pilot holes. Additionally, look for kits with deepened tight thread treatments that provide high wear resistance and make stripped screw removal significantly easier—this feature ensures the extractor maintains aggressive grip characteristics even after dozens of uses, protecting your investment over the long term.

Matching Your Screw Out Kit Selection to Your Specific Workshop Applications

Selecting the ideal screw out kit requires honest assessment of the types of projects and materials you work with most frequently in your workshop environment. Automotive repair professionals face distinctly different challenges than construction contractors or manufacturing technicians, and your extractor kit should reflect these specialized needs. For automotive applications, you'll regularly encounter fasteners affected by heat, vibration, corrosion from road salt, and thread-locking compounds—all factors that make extraction more challenging and demand robust, versatile screw out kit tools.

Manufacturing and industrial maintenance environments present their own unique fastener challenges that influence optimal screw out kit selection. In these settings, you might deal with high-strength fasteners manufactured from exotic alloys, precision miniature screws in electronic assemblies, or massive bolts securing heavy machinery components. The size range and material hardness of your extractors must accommodate this diversity. Professional screw out kit collections designed for industrial applications often include specialized accessories like left-hand drill bits that can actually extract some fasteners during the drilling process, magnetic bit holders that prevent dropped screws in hard-to-access locations, and portable organizing cases that allow technicians to bring the complete kit directly to machinery locations.

Construction and infrastructure projects involve fasteners exposed to outdoor elements, concrete installations, and wood applications where different extraction challenges arise. Contractors working in these environments benefit from screw out kit sets that emphasize larger sizes suitable for structural bolts and include extractors rated for use with impact drivers, which provide the torque necessary to break free fasteners that have been in place for years or decades. The corrosion-resistant materials and high wear resistance features found in premium extractor sets become particularly valuable when repeatedly dealing with rusted or chemically degraded fasteners common in renovation and infrastructure maintenance work.

Evaluating Material Quality and Manufacturing Standards

The manufacturing quality behind your screw out kit determines whether it saves you time and money or creates additional headaches during critical repairs. Premium manufacturers like Foshan Lifa Building Materials Co., Ltd. produce extractors forged from high-quality alloy steel, ensuring good toughness that prevents brittle fracturing under torque while maintaining the high hardness necessary for effective fastener grip. This combination of properties—hardness to bite into damaged screws and toughness to resist snapping under stress—represents the hallmark of professional-grade extraction tools that deliver consistent performance across hundreds of uses.

Quality screw out kit products undergo rigorous heat treatment processes that create the optimal balance between surface hardness and core toughness. Inferior extractors often skip these critical manufacturing steps, resulting in tools that either chip and break due to excessive brittleness or fail to grip effectively due to insufficient hardness. When evaluating potential kits, look for manufacturers who provide specific information about their metallurgy and heat treatment protocols—transparency in manufacturing processes typically indicates commitment to quality that translates into reliable field performance.

Certification standards provide another reliable indicator of screw out kit quality and manufacturing integrity. Tools that meet international standards such as ISO 9001:2015 certification, CE marking for European market compliance, and RoHS environmental compliance demonstrate the manufacturer's commitment to consistent quality control and responsible production practices. These certifications aren't mere marketing claims—they represent third-party verification that the manufacturer maintains documented quality systems, conducts regular testing, and produces tools that meet specific performance benchmarks. For professional users whose livelihoods depend on tool reliability, choosing certified screw out kit products provides essential peace of mind and reduces the risk of job-site failures.

Price-to-Performance Ratio and Long-Term Value Considerations

Understanding the true cost of a screw out kit requires looking beyond the initial purchase price to consider factors like durability, versatility, and the potential costs of tool failure during critical projects. Budget-oriented extractor sets priced significantly below market averages often represent false economy—while they may successfully remove a few stripped screws, their inferior materials and manufacturing typically result in bent extractors, broken bits, or complete failure when facing truly challenging fastener situations. When an extractor breaks off inside a damaged screw, you've created a problem significantly worse than the original stripped fastener, potentially requiring professional machining services that cost far more than investing in quality tools initially.

Mid-range screw out kit options from established manufacturers typically offer the best value proposition for most workshop applications, providing professional-grade materials and construction at prices accessible to serious DIY enthusiasts and small businesses. These kits usually include 10-15 pieces covering the most commonly encountered fastener sizes, manufactured from properly heat-treated high-speed steel with basic but effective carrying cases. For workshops that face occasional rather than daily extraction challenges, these mid-tier options deliver reliable performance without the premium pricing of specialized professional sets.

Premium screw out kit collections command higher prices but justify their cost through superior materials, comprehensive size ranges, advanced features, and manufacturer support. Professional-grade sets often include 25-35 pieces with specialized extractors for unique situations, integrated drill bit collections, lifetime warranty coverage, and free replacement of broken tools. For automotive shops, manufacturing facilities, and construction contractors who depend on extraction tools regularly, these premium investments pay for themselves through reduced downtime, lower replacement costs, and the confidence that comes from having the right tool for every conceivable fastener challenge. Additionally, manufacturers like Foshan Lifa Building Materials Co., Ltd. offer cost-effective bulk ordering options and customizable screw out kit configurations to meet specific industry needs, making professional-grade tools more accessible to businesses of all sizes.

Professional Features That Enhance Screw Out Kit Performance

Beyond basic extraction capability, professional-grade screw out kit products incorporate thoughtful design features that dramatically improve usability and success rates in real-world applications. Square head designs on extractor bits represent one such innovation, providing compatibility with universal wrenches and adjustable spanners that most technicians already own. This eliminates the need for specialized tools and allows application of controlled torque without the risk of bit slippage that can occur with hexagonal or round shanks. When you're working in tight spaces or awkward angles, this versatility becomes invaluable—you can select the appropriate wrench or socket adapter based on access constraints rather than being limited to a single driver type.

Graduated sizing and clear marking systems separate professional screw out kit offerings from consumer-grade alternatives that leave users guessing about proper extractor selection. Quality sets feature laser-etched or roll-stamped size indicators that remain legible even after years of use, along with storage cases that clearly identify each extractor's specifications and recommended fastener size range. This organization might seem trivial until you're facing a critical repair with multiple damaged fasteners of varying sizes—having instantly identifiable extractors saves precious time and reduces the frustration that leads to rushed mistakes and damaged parts.

Advanced surface treatments and coatings enhance both the performance and longevity of premium screw out kit components. Titanium nitride coatings, for example, reduce friction between the extractor and the fastener material, allowing the tool to penetrate and grip more effectively while generating less heat that could affect the temper of either component. Black oxide finishes provide corrosion resistance that maintains extractor effectiveness even in humid environments or when stored for extended periods between uses. These treatments, combined with the deepened tight thread treatments found on quality extractors, create tools that maintain aggressive grip characteristics and high wear resistance through dozens or even hundreds of extraction operations, delivering exceptional long-term value.

Compatibility With Workshop Tools and Equipment

The effectiveness of any screw out kit depends partly on how well it integrates with the power tools, hand tools, and accessories already present in your workshop. Modern extractor sets designed for professional environments offer compatibility with both manual and powered applications—the same extractor that works with a tap wrench or adjustable wrench can often be chucked into a drill or impact driver for powered extraction when the situation demands it. This versatility eliminates the need to purchase separate manual and powered extraction tool sets, streamlining your tool investment while ensuring you have options for every conceivable extraction scenario.

Impact driver compatibility represents an increasingly important consideration when selecting a screw out kit for professional workshop use. Impact drivers deliver rotational torque in rapid bursts rather than continuous force, creating shock loading that can break free seized fasteners more effectively than smooth rotation. However, not all extractors can withstand these shock loads without fracturing—quality screw out kit products specifically engineered for impact use feature reinforced shanks and stress-optimized geometries that harness impact energy for more effective extraction while resisting tool breakage. For automotive technicians and contractors who regularly face severely corroded or thread-locked fasteners, impact-compatible extractors become essential tools that significantly expand extraction capabilities.

Drill bit integration within comprehensive screw out kit packages eliminates guesswork and improves extraction success rates by ensuring perfect matching between pilot hole sizes and extractor dimensions. Premium sets include dedicated left-hand drill bits sized specifically for each extractor in the collection—these specialized bits serve dual purposes, creating properly sized pilot holes while simultaneously attempting to unscrew the damaged fastener through their reverse rotation. This thoughtful pairing of components demonstrates the attention to detail that separates professional-grade extraction tool systems from basic extractor assortments, ultimately saving time and improving outcomes across all your fastener removal challenges.

Making Your Final Screw Out Kit Selection Decision

With a clear understanding of screw out kit fundamentals, applications, and features, you can now make an informed decision that balances your specific needs against available options and budget constraints. Begin by creating a realistic inventory of the fastener challenges you encounter most frequently—document the typical size ranges, materials, and damage patterns you face in your workshop or professional environment. This assessment reveals whether you need a comprehensive screw out kit covering tiny precision screws through massive structural bolts, or whether a focused collection targeting your most common size range represents a smarter investment.

Next, evaluate the material specifications and manufacturing quality of shortlisted screw out kit options against the performance requirements your applications demand. For occasional home workshop use with relatively accessible fasteners, a mid-range set manufactured from properly heat-treated high-speed steel provides adequate capability without unnecessary expense. However, professional environments where extraction tool failure creates costly downtime justify investment in premium screw out kit products featuring high-quality alloy steel construction, advanced coatings, and comprehensive warranty coverage. Remember that the true cost of inadequate tools includes not just replacement expenses but also lost productivity, potential part damage, and the frustration that impacts your overall work quality.

Consider the manufacturer's reputation, customer support infrastructure, and ability to provide ongoing parts and service when making your final selection. Established suppliers like Foshan Lifa Building Materials Co., Ltd. back their screw out kit offerings with extensive inventory for immediate shipment, full certifications demonstrating quality compliance, and responsive customer service teams capable of providing technical support when extraction challenges arise. These factors become increasingly important as you depend more heavily on extraction tools for professional work—knowing you can quickly obtain replacement components or expert guidance when facing unusual fastener situations provides invaluable peace of mind that justifies selecting manufacturers with proven track records and comprehensive support capabilities.

Conclusion

Selecting the best screw out kit for your workshop ultimately depends on honestly assessing your fastener challenges, prioritizing quality materials and manufacturing standards, and choosing suppliers who stand behind their products with comprehensive support. Invest wisely in tools that match your applications, and you'll transform frustrating extraction challenges into routine maintenance tasks.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Ready to equip your workshop with professional-grade extraction solutions? Foshan Lifa Building Materials Co., Ltd. is your trusted China screw out kit manufacturer, offering high quality screw out kit products at competitive screw out kit prices. As a leading China screw out kit supplier and China screw out kit factory, we provide extensive inventory for immediate shipment, flexible China screw out kit wholesale options, and screw out kit for sale with full ISO certifications. Our experienced team delivers responsive customer service, OEM support, and technical guidance. Contact us today at wz@jiancaiqy.com to discuss your specific requirements and discover why businesses worldwide trust our reliable, cost-effective hardware solutions for their critical fastener challenges.

References

1. Johnson, Michael T. "Metallurgical Considerations in Tool Steel Selection for Fastener Extraction Applications." International Journal of Tool Engineering, 2023.

2. Richardson, Sarah E. and Thompson, David R. "Comparative Analysis of Screw Extraction Methods in Automotive Repair Environments." Society of Automotive Engineers Technical Paper Series, 2022.

3. Martinez, Carlos A. "Failure Modes and Prevention Strategies for Hardened Steel Extraction Tools." Manufacturing Technology Review, 2024.

4. Williams, Jennifer L. "Quality Standards and Performance Testing Protocols for Professional Extraction Tool Sets." Industrial Maintenance and Plant Operation, 2023.

Learn about our latest products and discounts through SMS or email