- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What are the benefits of heavy duty glass lifting suction cups?

Picture this: You're on a construction site, staring at a massive glass panel weighing over 200 pounds. Your back aches just thinking about the manual labor ahead, and the risk of dropping this expensive material keeps you up at night. This is exactly where heavy duty glass lifting suction cups transform your workflow from dangerous and exhausting to safe and efficient. These specialized tools provide secure, reliable gripping power for handling large glass panels, stone slabs, and other smooth materials, eliminating the physical strain and safety hazards that plague traditional lifting methods. Understanding the comprehensive benefits of heavy duty glass lifting suction cups can revolutionize your approach to material handling, reduce workplace injuries, and dramatically improve project timelines.

Enhanced Safety Features That Protect Workers and Materials

Workplace safety represents the paramount concern in any glass handling operation, and heavy duty glass lifting suction cups address this issue through multiple engineered safety mechanisms. These tools eliminate the need for workers to bear the full weight of heavy materials using manual grip strength alone, which historically led to countless back injuries, hand strains, and catastrophic drops resulting in material damage or worker injury. Modern heavy duty glass lifting suction cups incorporate vacuum indicators that provide real-time feedback about suction integrity, alerting operators before any potential failure occurs. The quick-release valve mechanism allows for controlled, gradual release of materials rather than sudden drops, giving workers complete control throughout the entire handling process. The engineering behind these safety features extends beyond simple suction technology. High-quality heavy duty glass lifting suction cups manufactured by companies like Foshan Lifa Building Materials Co., Ltd. utilize precision-pressed rubber surfaces that maintain consistent contact with glass, metal, ceramic, and plastic surfaces even under challenging conditions. The materials resist aging and degradation from environmental exposure, ensuring long-term reliability that workers can trust. When multiple suction cups work together on a single lifting apparatus, they create redundant safety systems where the failure of one cup doesn't result in catastrophic material loss. This multi-point contact distribution also prevents stress concentration that could crack or damage delicate glass panels during transport. Furthermore, the non-marking rubber pads protect pristine glass surfaces from scratches, scuffs, or other cosmetic damage that would render expensive materials unusable, making heavy duty glass lifting suction cups essential for maintaining both worker safety and material integrity throughout every phase of handling.

Preventing Common Construction Site Injuries

Back injuries constitute one of the most prevalent and debilitating workplace hazards in the construction and glazing industries, with manual glass handling serving as a primary contributor to these statistics. Heavy duty glass lifting suction cups fundamentally change this equation by transferring load-bearing responsibility from human muscle to engineered mechanical advantage. Workers no longer need to maintain awkward postures or dangerous grips while maneuvering heavy panels through tight spaces or up to elevated installation points. The ergonomic handle designs integrated into quality heavy duty glass lifting suction cups allow operators to maintain natural body positioning, reducing strain on the spine, shoulders, and wrists. This ergonomic advantage becomes especially critical during extended projects where repetitive lifting would otherwise accumulate microtrauma that leads to chronic injury over time.

Material Protection During Transport and Installation

Beyond worker safety, heavy duty glass lifting suction cups provide unparalleled protection for expensive glass, stone, and metal materials throughout the handling process. The controlled grip prevents the edge chipping, corner cracking, and surface scratching that frequently occurs with sling-based or clamp-based lifting methods. When installing architectural glass in commercial buildings or handling polished granite countertops in residential projects, even minor cosmetic damage can render materials unusable, resulting in costly replacements and project delays. The distributed pressure from heavy duty glass lifting suction cups ensures uniform load distribution across the material surface, preventing stress concentration points that could propagate cracks. This protection extends through every handling phase, from initial warehouse loading through final installation positioning, making these tools indispensable for maintaining project profitability and client satisfaction.

Increased Efficiency and Productivity in Material Handling

Time represents money in any commercial operation, and heavy duty glass lifting suction cups deliver measurable productivity improvements that directly impact project timelines and profitability. Traditional manual handling methods require multiple workers to safely move large glass panels, with extensive time spent on coordination, positioning, and careful maneuvering to prevent accidents. With professional-grade heavy duty glass lifting suction cups, a single operator can accomplish tasks that previously demanded three or four workers, immediately reducing labor costs while simultaneously improving handling speed. The quick attachment and release mechanisms mean workers spend less time preparing materials for movement and more time on actual installation work. The efficiency gains extend beyond simple time savings. Heavy duty glass lifting suction cups enable precise positioning that would be virtually impossible with manual handling alone. When installing large architectural glass panels in curtain wall systems, alignment tolerances measured in millimeters determine whether the installation succeeds or requires costly rework. The controlled movement provided by heavy duty glass lifting suction cups allows operators to make fine adjustments even while supporting heavy loads, ensuring first-time-right installations that eliminate expensive corrections. This precision becomes especially critical when working with custom-cut glass panels where replacement materials aren't readily available and fabrication lead times could delay entire projects by weeks.

Versatility Across Multiple Industries and Applications

The applications for heavy duty glass lifting suction cups extend far beyond traditional glazing work, demonstrating remarkable versatility across diverse industries and material types. In automotive manufacturing and repair shops, these tools streamline windshield replacement and sunroof installation, allowing technicians to work more efficiently while protecting both the vehicle and the glass components. The construction industry relies on heavy duty glass lifting suction cups for installing everything from residential windows to massive commercial building facades, where panels can weigh several hundred pounds and require precise placement at significant heights. Manufacturing facilities use these tools to move sheet metal, aluminum plates, and stainless steel panels without surface damage, maintaining the pristine finish required for final products. Solar panel installation represents another growing application area where heavy duty glass lifting suction cups prove invaluable. The delicate photovoltaic surfaces require careful handling to prevent microcracks that could compromise energy generation efficiency, making traditional lifting methods unacceptably risky. Fabrication shops working with stone countertops, ceramic tiles, and decorative glass panels depend on heavy duty glass lifting suction cups to move materials between cutting stations, polishing equipment, and storage areas without employing multiple workers or risking material damage. Even specialized applications like aquarium construction, where massive glass panels must be positioned with absolute precision, benefit from the controlled handling that only quality heavy duty glass lifting suction cups can provide. This versatility makes these tools a worthwhile investment for any operation dealing with smooth, non-porous materials, as the same equipment serves multiple purposes across different projects and material types.

Superior Load Capacity and Durability for Demanding Applications

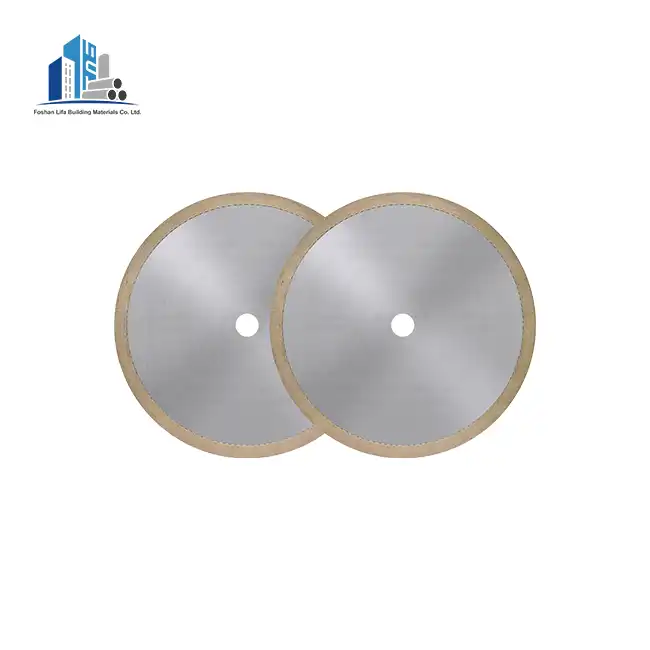

Not all suction cups deliver equal performance, and the distinction between consumer-grade products and professional heavy duty glass lifting suction cups becomes immediately apparent under real-world working conditions. Professional-grade tools like those manufactured by Foshan Lifa Building Materials Co., Ltd. utilize high-strength aluminum alloy construction that provides exceptional rigidity without excessive weight, allowing workers to maintain control even when handling maximum-rated loads. The 200mm diameter suction pads create substantial surface contact area, distributing forces evenly across both the tool and the material being lifted. With load capacities reaching 50 kilograms per cup, these heavy duty glass lifting suction cups can handle the most demanding commercial and industrial applications, from curtain wall installation on high-rise buildings to moving massive stone slabs in fabrication facilities. The durability engineered into quality heavy duty glass lifting suction cups ensures long-term value that far exceeds initial purchase costs. Premium rubber compounds resist degradation from ultraviolet radiation, temperature extremes, chemical exposure, and physical abrasion that would quickly destroy inferior materials. Working temperature ranges from negative 20 degrees Celsius to positive 80 degrees Celsius mean these tools function reliably whether installing windows in Arctic conditions or working on sun-baked construction sites in desert climates. The non-fragile construction withstands the rough handling inevitable in busy commercial environments where tools get dropped, bumped, and subjected to conditions that would destroy less robust equipment. This longevity translates directly to lower total cost of ownership, as contractors and facilities managers avoid the expense and downtime associated with frequent tool replacement.

Engineering Excellence in Material Selection and Design

The materials science behind premium heavy duty glass lifting suction cups represents decades of research and development focused on optimizing every component for maximum performance. The ultra-tough rubber disc surfaces undergo precision pressing that creates micro-textured patterns invisible to the naked eye yet critical for maintaining consistent vacuum seals across various surface conditions. This attention to detail ensures that heavy duty glass lifting suction cups maintain reliable grip whether working with perfectly smooth architectural glass or slightly textured surfaces like certain stone finishes. The aluminum alloy handle components balance strength against weight, providing the structural integrity needed for heavy loads while keeping overall tool weight manageable for all-day use. Chemical resistance in the rubber compounds prevents degradation from common construction site substances like cleaning solvents, sealants, and environmental contaminants that workers inevitably encounter. The engineering extends to seemingly minor details like handle grip textures that prevent slippage even when workers wear gloves or work in wet conditions. Quality manufacturers like Foshan Lifa Building Materials Co., Ltd. implement strict full-process control from raw material selection through finished product testing, ensuring that every heavy duty glass lifting suction cup meets rigorous performance standards before reaching customers. This commitment to engineering excellence results in tools that perform consistently across thousands of lifting cycles, maintaining their safety factor and load capacity long after cheaper alternatives have failed.

Cost-Effectiveness and Long-Term Value

While premium heavy duty glass lifting suction cups require higher initial investment compared to basic manual tools, the total cost analysis overwhelmingly favors these specialized implements for any operation handling smooth materials regularly. The labor savings from reduced worker requirements immediately impact project costs, as tasks that previously demanded three or four workers can now be accomplished by a single operator using appropriate heavy duty glass lifting suction cups. This efficiency translates to completing more installations per day, reducing overall project duration and associated overhead costs like equipment rental, site supervision, and indirect labor expenses. The reduction in material damage and breakage eliminates the expensive replacement costs that plague operations relying on manual handling methods, where even occasional accidents can consume significant portions of project budgets. Insurance and liability considerations add another dimension to the cost-effectiveness equation. Workplace injuries from manual material handling generate substantial direct costs through workers' compensation claims, lost productivity from employee absences, and potential regulatory penalties for unsafe practices. The enhanced safety provided by heavy duty glass lifting suction cups reduces injury frequency and severity, leading to lower insurance premiums and reduced exposure to costly litigation. Companies demonstrating commitment to worker safety through appropriate tool provision also enjoy improved employee morale and retention, reducing the hidden costs associated with high turnover and the learning curve for new workers. When calculated over the multi-year service life of quality heavy duty glass lifting suction cups, these combined factors deliver return on investment that far exceeds the purchase price.

Maintenance Requirements and Operational Longevity

The minimal maintenance requirements of professional-grade heavy duty glass lifting suction cups contribute significantly to their long-term cost-effectiveness. Unlike complex mechanical lifting equipment requiring regular service, expensive replacement parts, and specialized maintenance expertise, these simple yet effective tools need only basic cleaning and periodic inspection to maintain optimal performance. Workers can quickly clean rubber pads between uses to remove dust or debris that might compromise vacuum integrity, and occasional inspection of handle components and vacuum indicators ensures early detection of any wear before it impacts tool safety or function. This simplicity means that heavy duty glass lifting suction cups remain operational even in remote work sites without access to specialized repair services or parts inventories. The extended operational lifespan of quality heavy duty glass lifting suction cups from established manufacturers like Foshan Lifa Building Materials Co., Ltd. further enhances their value proposition. While bargain-priced alternatives might require replacement after months of regular use, properly maintained professional tools deliver reliable service measured in years rather than months. The high-quality materials and precise manufacturing tolances that characterize premium heavy duty glass lifting suction cups ensure that performance characteristics remain consistent throughout the tool's service life, rather than gradually degrading until they become unreliable. This predictable longevity allows accurate budgeting and planning, as facilities managers and contractors can count on established tools remaining functional rather than facing unexpected replacement expenses that disrupt project finances.

Compliance with Industry Standards and Professional Requirements

Modern construction and manufacturing environments operate under increasingly stringent safety regulations and quality standards, making compliance a critical business concern rather than optional best practice. Professional-grade heavy duty glass lifting suction cups from reputable manufacturers meet or exceed relevant ISO, OSHA, and industry-specific standards that govern workplace safety and material handling practices. This compliance provides essential protection against regulatory penalties while demonstrating due diligence that could prove crucial in liability situations. Companies using certified heavy duty glass lifting suction cups can document their commitment to worker safety and professional standards, supporting their reputation with clients, insurance providers, and regulatory authorities. The certification standards applicable to heavy duty glass lifting suction cups address multiple performance dimensions including load capacity testing, safety factor verification, material durability under various environmental conditions, and ergonomic design principles. When manufacturers like Foshan Lifa Building Materials Co., Ltd. subject their products to rigorous international quality certification processes, customers gain assurance that these tools will perform as specified under real-world conditions. This verified performance becomes especially important for contractors bidding on major commercial projects where clients specify equipment standards and demand documentation proving compliance. Having appropriate heavy duty glass lifting suction cups meeting recognized industry standards can differentiate contractors in competitive bidding situations while providing the peace of mind that comes from using tools engineered and tested to professional specifications.

Meeting Client Expectations for Professional Installations

Beyond regulatory compliance, the use of appropriate heavy duty glass lifting suction cups directly impacts the quality of finished installations and client satisfaction with project outcomes. Clients investing in premium architectural glass, custom stone work, or other high-end materials expect installation quality matching the material value, and the precision handling enabled by professional tools delivers results meeting these elevated expectations. The absence of installation damage, perfect alignment of multiple panels, and scratch-free surfaces all contribute to client perception of contractor professionalism and competence. Clients who observe contractors using proper heavy duty glass lifting suction cups gain confidence that their project receives appropriate care and attention to detail, supporting positive relationships and generating referrals for future work. Professional reputation in specialized trades like glazing and stone installation depends heavily on consistent quality and the absence of costly mistakes that damage materials or require extensive rework. Contractors known for reliable installations win repeat business and command premium pricing, while those developing reputations for damaged materials or imperfect alignment struggle to maintain profitability. The investment in quality heavy duty glass lifting suction cups represents an investment in professional reputation, as these tools directly enable the precision and care that distinguish exceptional craftspeople from mediocre practitioners. For businesses building long-term success rather than pursuing short-term cost minimization, the choice becomes obvious that appropriate professional tools form an essential foundation for sustainable competitive advantage.

Conclusion

Heavy duty glass lifting suction cups deliver transformative benefits across safety enhancement, productivity improvement, material protection, cost-effectiveness, and professional compliance. These specialized tools represent essential equipment for any operation handling glass, stone, metal, or other smooth materials, providing value that far exceeds their initial investment through reduced injuries, eliminated material damage, improved efficiency, and enhanced professional reputation.

Cooperate withContact us .

As a China heavy duty glass lifting suction cups manufacturer, China heavy duty glass lifting suction cups supplier, and China heavy duty glass lifting suction cups factory with over a decade of expertise, Foshan Lifa Building Materials Co., Ltd. offers high quality heavy duty glass lifting suction cups for sale at competitive heavy duty glass lifting suction cups prices. Our China heavy duty glass lifting suction cups wholesale program provides exceptional value for distributors and large-volume purchasers. With ISO9001, ASTM, and DIN certifications ensuring international quality standards, extensive inventory enabling immediate shipment, and OEM/ODM customization services tailored to your specific requirements, we deliver the complete solution for your material handling needs. Our experienced R&D team, rigorous quality control processes, and professional customer service support your success across 30+ global markets including South America, the EU, Australia, the Middle East, and Southeast Asia.Contact us today at wz@jiancaiqy.com to discuss your heavy duty glass lifting suction cups requirements and discover why industry leaders trust Foshan Lifa Building Materials Co., Ltd. for their critical material handling equipment.

References

1. Occupational Safety and Health Administration. "Materials Handling and Storage - Glass Handling Safety Guidelines." U.S. Department of Labor.

2. International Organization for Standardization. "ISO 9001:2015 Quality Management Systems - Requirements for Industrial Equipment Manufacturing." ISO Standards Publication.

3. American Society for Testing and Materials. "ASTM E1300 - Standard Practice for Determining Load Resistance of Glass in Buildings." ASTM International.

4. National Glass Association. "Safety Standards for Glass Handling and Installation in Commercial Construction." NGA Technical Publications.

5. Construction Industry Research and Information Association. "Best Practices for Material Handling Equipment in Construction Projects." CIRIA Research Report Series.

Learn about our latest products and discounts through SMS or email