- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is a riveter tool used for?

Are you struggling with weak joints that constantly fail under pressure? Do traditional fastening methods leave you frustrated when working in tight spaces where access to both sides of materials is impossible? A Manual Hand Riveter is the precision tool that transforms challenging fastening scenarios into seamless assembly operations. This comprehensive guide reveals how riveting tools revolutionize permanent fastening across industries, providing unmatched strength and reliability where conventional methods fall short, making your projects more efficient and structurally sound.

Understanding Manual Hand Riveter Applications and Functions

Manual Hand Riveters serve as essential mechanical fastening tools designed to create permanent joints between materials through the installation of rivets. These versatile instruments operate by drawing a mandrel through the rivet body, causing deformation that secures materials together with exceptional clamping force. The Manual Hand Riveter excels in applications where access to the reverse side of materials is limited or impossible, making it invaluable for blind riveting operations. The fundamental operation of a Manual Hand Riveter involves inserting the rivet into pre-drilled holes, positioning the tool's nosepiece over the rivet head, and applying leverage to pull the mandrel through the rivet body. This process creates a mushroomed tail on the blind side while the mandrel breaks at a predetermined stress point, leaving a clean, flush finish. Professional tradespeople rely on Manual Hand Riveters for their ability to generate substantial clamping forces with minimal operator effort, thanks to their multi-lever design that amplifies input force significantly.

-

Primary Industrial Applications of Manual Hand Riveters

Manual Hand Riveters find extensive use across automotive manufacturing and repair operations, where they secure body panels, trim components, and structural elements. The aerospace industry depends heavily on these tools for assembling aircraft components, where weight considerations and access limitations make riveting the preferred fastening method. HVAC contractors utilize Manual Hand Riveters for ductwork assembly, where the tools' ability to work in confined spaces proves invaluable. Construction professionals employ Manual Hand Riveters for metal fabrication projects, including steel framing, roofing applications, and architectural metalwork. The tools' portability and independence from power sources make them ideal for field work where electrical connections are unavailable. Marine applications benefit from the corrosion-resistant rivets installed with Manual Hand Riveters, ensuring long-lasting assemblies in harsh saltwater environments.

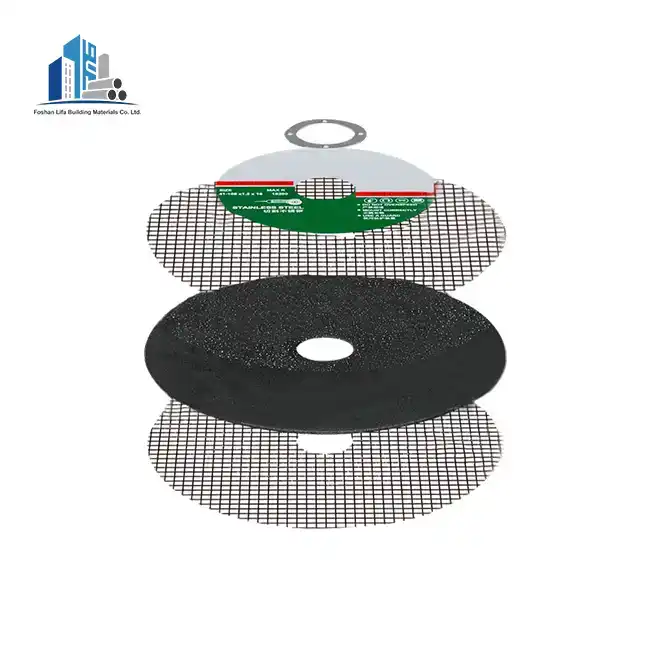

Essential Features of Professional Manual Hand Riveter Tools

Modern Manual Hand Riveters incorporate ergonomic design principles that reduce operator fatigue during extended use periods. The gun head receives blackening treatment for enhanced sturdiness, durability, and rust resistance, extending the tool's operational lifespan in demanding industrial environments. Multi-lever designs significantly reduce the force required for rivet installation, making these tools accessible to operators across various strength levels while maintaining professional performance standards. Heat-treated steel construction ensures Manual Hand Riveters withstand repeated high-stress operations without mechanical failure. Ergonomic rubber grips provide secure handling even in wet or oily conditions, while the tools' compatibility with multiple rivet sizes eliminates the need for multiple specialized instruments. Professional-grade Manual Hand Riveters typically accommodate rivet diameters ranging from 2.4mm to 4.8mm, covering the majority of industrial fastening requirements.

-

Quality Construction and Material Specifications

Premium Manual Hand Riveters utilize heat-treated steel components that maintain structural integrity under extreme loading conditions. The 10.5-inch length provides optimal leverage while remaining manageable for precision work, and the 1.2-pound weight strikes an ideal balance between stability and operator comfort. These specifications ensure consistent performance across diverse applications while minimizing user fatigue during extended operation periods. The ergonomic rubber grip construction provides enhanced control and comfort, featuring non-slip surfaces that maintain secure handling in various working conditions. Professional Manual Hand Riveters include comprehensive warranty coverage, typically extending for two years, demonstrating manufacturer confidence in product durability and performance. This warranty protection ensures cost-effective ownership while providing peace of mind for professional users who depend on tool reliability for their livelihood.

Manual Hand Riveter Performance in Specialized Industries

Automotive assembly lines depend on Manual Hand Riveters for their precision and repeatability in high-volume production environments. These tools ensure consistent joint quality while accommodating the rapid pace required in modern manufacturing facilities. Aerospace component manufacturing demands the exceptional reliability that Manual Hand Riveters provide, where failure is not an option and every fastener must meet stringent quality standards. Metal fabrication workshops utilize Manual Hand Riveters for their versatility in handling various material combinations and thicknesses. The tools excel in both production line scenarios and field maintenance applications, offering consistent performance regardless of environmental conditions. Construction sites benefit from the Manual Hand Riveter's ability to create strong, permanent joints in structural applications where traditional welding may be impractical or prohibited.

-

Technical Advantages in Professional Applications

Manual Hand Riveters create joints that distribute stress across larger surface areas compared to point-contact fasteners like screws or bolts. This stress distribution characteristic makes riveted assemblies particularly suitable for applications subject to vibration, thermal cycling, or dynamic loading conditions. The permanent nature of riveted joints eliminates concerns about loosening over time, a common issue with threaded fasteners in high-vibration environments. The blind riveting capability of Manual Hand Riveters enables assembly operations in situations where conventional fastening methods prove impossible or impractical. This advantage becomes particularly valuable in closed structures, hollow assemblies, or applications where space constraints prevent access to the reverse side of materials. Professional contractors recognize these tools as essential equipment for efficient project completion while maintaining superior joint quality and structural integrity.

Selecting the Right Manual Hand Riveter for Your Application

Professional tool selection requires careful consideration of application requirements, material specifications, and operational demands. Manual Hand Riveters offer various capacity ranges, with models designed for light-duty assembly work through heavy-industrial applications. Understanding the relationship between rivet size, material thickness, and required clamping force ensures optimal tool selection for specific projects. Compatibility considerations include rivet material types, diameter ranges, and grip length capabilities. Professional-grade Manual Hand Riveters typically accommodate aluminum, steel, and stainless steel rivets across diameter ranges from 2.4mm to 4.8mm. This versatility eliminates the need for multiple specialized tools while ensuring consistent results across diverse material combinations and assembly requirements.

-

Quality Assurance and Certification Standards

Professional Manual Hand Riveters comply with international quality standards including ISO 9001 and CE certifications, ensuring consistent performance and safety in industrial applications. These certifications demonstrate manufacturer commitment to quality control processes and product reliability, providing confidence for professional users who depend on tool performance for project success. Quality control measures extend throughout the manufacturing process, from raw material selection through final inspection and testing. Professional manufacturers implement strict full-process control protocols that guarantee excellent product consistency and reliable large-scale supply capabilities. This comprehensive approach ensures that every Manual Hand Riveter meets demanding professional standards while providing the durability and performance required in industrial applications.

Conclusion

Manual Hand Riveters represent essential tools for creating permanent, high-strength joints across diverse industrial applications, offering unmatched versatility and reliability for professional fastening operations.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Partner with Foshan Lifa Building Materials Co., Ltd., your trusted China Manual Hand Riveter factory and China Manual Hand Riveter supplier. As a leading China Manual Hand Riveter manufacturer offering China Manual Hand Riveter wholesale solutions, we provide High Quality Manual Hand Riveter for sale at competitive Manual Hand Riveter price points. Our extensive inventory ensures immediate shipment with rigorous quality control, competitive pricing, and flexible OEM support. Contact our experienced team today at wz@jiancaiqy.com for expert guidance and exceptional customer service.

FAQ

Q: What materials can Manual Hand Riveters join together?

A: Manual Hand Riveters can effectively join metals, plastics, wood, and composite materials using appropriate rivet types for each application.

Q: What rivet sizes do Manual Hand Riveters typically accommodate?

A: Professional Manual Hand Riveters commonly handle rivet diameters from 2.4mm to 4.8mm, covering most industrial fastening requirements.

Q: Do Manual Hand Riveters require special maintenance?

A: Regular cleaning, lubrication of moving parts, and proper storage ensure optimal performance and extended tool life.

Q: Can Manual Hand Riveters work in confined spaces?

A: Yes, their compact design and blind riveting capability make them ideal for tight spaces where rear access is impossible.

References

1. Bickford, John H. "An Introduction to the Design and Behavior of Bolted Joints" - Marcel Dekker Inc.

2. Smith, Robert J. "Fastening and Joining Reference Guide" - Industrial Press Inc.

3. Thompson, Michael K. "Mechanical Fastening Systems for Industrial Applications" - McGraw-Hill Professional

4. Williams, David A. "Structural Riveting Handbook" - American Society of Mechanical Engineers

Learn about our latest products and discounts through SMS or email