- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What type of threads do acetylene hoses have?

Picture this scenario: you're in the middle of a critical welding project, and suddenly you realize your acetylene hose won't connect to your torch or regulator. The threads don't match, your workflow stops, and precious time is wasted troubleshooting connection issues. Understanding acetylene hose thread types isn't just technical knowledge—it's essential for operational efficiency and workplace safety. Acetylene hoses typically feature left-hand threads with standardized sizes, most commonly 9/16"-18 for B-size fittings and 3/8"-24 for A-size connections, designed specifically to prevent dangerous cross-connections with oxygen equipment. When selecting equipment like the Premium Smooth-Surface Acetylene Hose from reliable manufacturers, knowing these thread specifications ensures seamless integration with your existing welding setup while maintaining the highest safety standards.

Understanding Acetylene Hose Thread Standards and Classifications

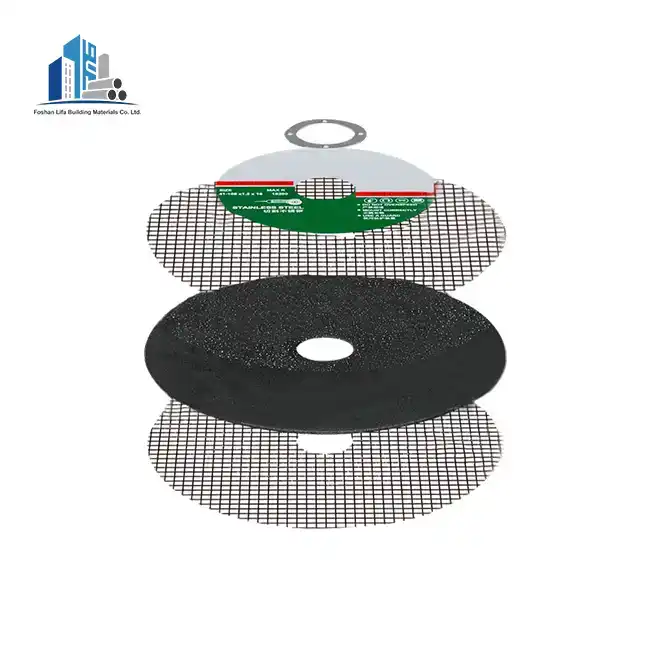

The threading system used on acetylene hoses follows strict industry standards designed with both functionality and safety as primary concerns. Acetylene hoses utilize left-hand threads as a critical safety feature, preventing accidental connection of fuel gas hoses to oxygen or other non-fuel gas equipment. This distinction is immediately recognizable through small machined cuts or notches on the coupling nuts, which serve as visual and tactile indicators of left-hand threading. The Premium Smooth-Surface Acetylene Hose adheres to these standardized thread specifications, ensuring compatibility across various welding applications while maintaining the integrity of your gas delivery system. The most prevalent thread standard in the industry is the American National Fine (NF) thread series, specifically designed for welding hose connections. For B-size fittings, which represent approximately 95% of the market for standard-duty applications, the thread specification is 9/16"-18 NF-3, meaning a 9/16-inch diameter with 18 threads per inch. A-size fittings, used for light-duty applications, feature 3/8"-24 NF-3 threads. These specifications are not arbitrary—they've been engineered to provide optimal sealing characteristics while allowing for quick, secure connections that can withstand the pressure demands of acetylene delivery. The Premium Smooth-Surface Acetylene Hose manufactured by Foshan Lifa Building Materials Co., Ltd. comes equipped with these standard thread configurations, manufactured to precise tolerances that ensure leak-free operation under working pressures up to 300 PSI.

-

BSP Thread Standards in Global Markets

Beyond the American thread standards, British Standard Pipe (BSP) threading is commonly encountered in international markets, particularly in European, Australian, and Middle Eastern applications. BSP threads can initially confuse users because the measurement refers to the internal bore diameter of the pipe rather than the external thread diameter. For instance, a 3/8" BSP thread actually measures over 1/2 inch in external diameter. Acetylene connections using BSP standards maintain the left-hand thread convention for safety, with 1/4" BSP typically used on torch ends where small torches are employed, while larger BSP sizes accommodate higher gas volumes. The Premium Smooth-Surface Acetylene Hose can be supplied with BSP-compatible fittings for markets requiring this specification, demonstrating the flexibility of quality manufacturers to meet regional requirements while maintaining safety standards.

-

Thread Size Selection Based on Application Requirements

Selecting the appropriate thread size for your acetylene hose depends primarily on the gas volume requirements of your specific application. Light-duty work such as HVAC repairs, jewelry making, or craft applications typically utilize A-size fittings with their 3/8"-24 threads, as these smaller connections are perfectly adequate for the lower gas flow rates required. Standard industrial applications including general metal fabrication, construction welding, and automotive repair rely heavily on B-size fittings with 9/16"-18 threads, which handle medium gas volumes efficiently. The Premium Smooth-Surface Acetylene Hose with its 1/4-inch inner diameter and B-size fittings represents the ideal solution for these standard-duty applications, providing optimal flow characteristics without unnecessary bulk or weight. Heavy-duty applications such as large-scale cutting operations, scarfing, or industrial demolition require C-size fittings with 7/8"-14 threads, and in extreme cases, D-size fittings measuring 1-1/4"-12 threads. These larger connections ensure sufficient gas volume delivery to support the intense combustion requirements of heavy cutting equipment. Understanding your application's gas consumption needs allows you to select the Premium Smooth-Surface Acetylene Hose configuration that perfectly matches your operational requirements, eliminating potential bottlenecks in gas delivery that could compromise cut quality or work speed.

Premium Smooth-Surface Acetylene Hose: Engineering Excellence for Reliable Performance

Modern acetylene hose design represents decades of engineering refinement focused on safety, durability, and performance optimization. The Premium Smooth-Surface Acetylene Hose exemplifies this evolution through its advanced construction incorporating high-grade synthetic rubber compounds that deliver exceptional resistance to the unique challenges of acetylene service. The smooth interior surface is a critical design feature that minimizes friction losses as acetylene flows through the hose, maintaining consistent pressure at the torch while reducing the risk of turbulence-induced degradation of the hose lining. This smooth-bore construction, combined with proper thread fittings, ensures your welding equipment receives optimal gas flow for consistent flame characteristics and superior work results. The material composition of quality acetylene hoses like the Premium Smooth-Surface Acetylene Hose must balance multiple performance requirements. Acetylene is chemically reactive and can deteriorate inferior rubber compounds over time, leading to hose failure. High-quality synthetic rubber formulations provide acetone resistance (acetylene is typically dissolved in acetone for safe transport), oil resistance from workshop contaminants, and fire-retardant properties that enhance operational safety. The hose construction includes multiple layers: an inner tube that contacts the gas, reinforcement layers that provide pressure resistance and burst protection, and an outer cover that protects against physical damage, UV degradation, and environmental factors. Foshan Lifa Building Materials Co., Ltd. employs strict quality control throughout the manufacturing process, ensuring each Premium Smooth-Surface Acetylene Hose meets or exceeds standards including ISO 9001, ASTM, and DIN specifications.

-

Temperature Performance and Flexibility Characteristics

Working environments for welding equipment vary dramatically from frigid outdoor construction sites to hot industrial facilities. The Premium Smooth-Surface Acetylene Hose is engineered to maintain flexibility and performance across a temperature range from -20°C to 70°C (-4°F to 158°F), ensuring reliable operation regardless of ambient conditions. This temperature resilience comes from specially formulated rubber compounds that resist both cold-temperature stiffening and heat-induced softening. Cold-resistant properties are particularly critical for outdoor applications where hoses must remain flexible enough for easy handling without becoming brittle and crack-prone. The anti-aging additives incorporated into the Premium Smooth-Surface Acetylene Hose formulation protect against oxidation and ozone degradation, significantly extending service life even under challenging environmental conditions. Flexibility is not merely a convenience feature—it directly impacts operational efficiency and safety. A flexible hose reduces operator fatigue during extended welding sessions, minimizes kinking that can restrict gas flow or cause pressure spikes, and reduces the physical strain on connection threads that could lead to loosening or leakage. The Premium Smooth-Surface Acetylene Hose maintains its flexibility throughout its service life, resisting the hardening that affects lower-quality hoses as they age. This consistent flexibility, combined with properly maintained thread connections, ensures your welding equipment operates safely and efficiently from the first use through years of demanding service.

-

Pressure Ratings and Safety Margins

Understanding pressure specifications is fundamental to safe acetylene hose operation. The Premium Smooth-Surface Acetylene Hose features a working pressure rating of 300 PSI with a burst pressure of 1200 PSI, providing a robust 4:1 safety factor that exceeds industry minimum requirements. This safety margin accounts for pressure surges that can occur during regulator adjustment, ensures reliable performance even with some hose wear, and provides peace of mind in demanding applications. The thread connections are equally critical to this pressure containment system—properly tightened fittings with left-hand threads on acetylene service create metal-to-metal seals reinforced by the hose coupling design that can reliably contain these pressures throughout the hose's service life. The burst pressure specification represents the point at which catastrophic hose failure would occur, but quality hoses like the Premium Smooth-Surface Acetylene Hose are designed so this limit is never approached during normal service. Regular inspection of thread connections, checking for signs of wear, corrosion, or damage, and immediate replacement of any compromised hose sections are essential maintenance practices. Foshan Lifa Building Materials Co., Ltd. manufactures the Premium Smooth-Surface Acetylene Hose with reinforcement layers that distribute pressure stress evenly, preventing weak points that could lead to premature failure. This robust construction, combined with proper thread engagement and regular maintenance, ensures your acetylene delivery system operates safely within its design parameters.

Thread Connection Best Practices and Maintenance Protocols

Proper installation and maintenance of threaded acetylene hose connections directly impact both safety and operational reliability. Left-hand threads require a counterclockwise rotation for tightening—opposite to conventional right-hand threads—which can initially confuse operators accustomed to oxygen connections. The Premium Smooth-Surface Acetylene Hose fittings should be hand-tightened firmly, then given an additional quarter to half turn with appropriate wrenches to ensure proper sealing without over-tightening that could damage the threads or coupling components. Cross-threading is a common installation error that compromises connection integrity; taking time to carefully align threads before applying force prevents this costly mistake. Always verify that you're connecting acetylene hoses only to acetylene service points—the left-hand thread design specifically prevents cross-connection, but vigilance remains essential. Thread inspection should be part of regular equipment maintenance protocols. Visual examination for damaged, worn, or corroded threads should be performed before each connection, with any compromised fittings immediately removed from service. The machined notches that identify left-hand threads on the Premium Smooth-Surface Acetylene Hose couplings should remain clearly visible; if these indicators are worn away, the fitting should be replaced to prevent potential confusion during future connections. Thread lubricants should never be used on oxygen or acetylene fittings, as petroleum-based lubricants create serious fire and explosion hazards. The metal-to-metal seal design of properly manufactured fittings like those supplied with the Premium Smooth-Surface Acetylene Hose requires no additional sealants when threads are in good condition and properly tightened.

-

Troubleshooting Common Thread Connection Issues

Even with quality equipment like the Premium Smooth-Surface Acetylene Hose, connection problems can occasionally arise. Difficulty threading fittings together often indicates thread damage, cross-threading attempts, or presence of foreign material in the threads. If threads won't engage smoothly after careful alignment, inspect both male and female components for damage, burrs, or embedded debris. Minor thread damage can sometimes be addressed with appropriate thread files or dies, but significantly damaged fittings should be replaced rather than repaired. Persistent leaks at threaded connections despite proper tightening suggest thread wear, seal surface damage, or over-tightening that has deformed the coupling components. The Premium Smooth-Surface Acetylene Hose from Foshan Lifa Building Materials Co., Ltd. is manufactured with precision thread cutting that ensures proper engagement, but connecting to damaged or poorly manufactured equipment can still create problems requiring systematic troubleshooting. Gas leaks at threaded connections represent serious safety hazards requiring immediate attention. Testing for leaks using approved leak detection solutions (never flame testing) should be performed after any connection or disconnection of acetylene hoses. Small bubbles indicating minor leakage often respond to additional tightening, but persistent leakage requires investigation of thread condition, seal surfaces, and fitting integrity. The robust construction of the Premium Smooth-Surface Acetylene Hose fittings, combined with proper installation practices, minimizes leakage risks, but vigilance remains essential. Any fitting that cannot be made leak-free through proper tightening should be replaced immediately, as acetylene leaks create fire and explosion hazards that far exceed the cost of replacement components.

Selecting the Right Premium Smooth-Surface Acetylene Hose Configuration

Matching your acetylene hose to your specific application requirements involves considering multiple factors beyond just thread type. Hose length significantly impacts operational convenience and safety—longer hoses provide greater working radius and allow cylinder placement farther from the work area, reducing heat exposure to the cylinder. However, excessively long hoses can create pressure drop issues that affect flame characteristics, particularly with smaller diameter hoses. The Premium Smooth-Surface Acetylene Hose is available in various lengths to suit different application requirements, from compact 25-foot configurations for shop work to extended 50-foot or 100-foot lengths for construction sites or large fabrication facilities where mobility and reach are paramount. Inner diameter selection directly affects gas flow capacity and pressure drop characteristics. The Premium Smooth-Surface Acetylene Hose standard 1/4-inch (6.3mm) inner diameter provides optimal flow for B-size connection applications, handling the gas volumes required for standard cutting and welding operations without excessive pressure loss. This diameter specification, combined with the smooth interior surface, ensures consistent gas delivery even during demanding operations. For light-duty applications with A-size fittings, smaller inner diameters may be appropriate, while heavy-duty operations with C or D-size connections require correspondingly larger bore hoses. Foshan Lifa Building Materials Co., Ltd. offers the Premium Smooth-Surface Acetylene Hose in configurations matched to standard thread sizes, eliminating guesswork in component selection.

-

OEM and Customization Options for Specialized Applications

While standardized products like the Premium Smooth-Surface Acetylene Hose serve the vast majority of applications perfectly, certain specialized operations require customized solutions. Foshan Lifa Building Materials Co., Ltd. provides comprehensive OEM and ODM services, allowing customization of thread types, hose lengths, fitting configurations, and even material formulations to meet unique application requirements. Industries with specific regulatory requirements, extreme operating conditions, or non-standard equipment interfaces benefit from these customization capabilities. The company's experienced engineering team works directly with customers to understand application challenges and develop Premium Smooth-Surface Acetylene Hose variants that address these specific needs while maintaining the quality and safety standards that define the product line. Custom thread configurations might be required for legacy equipment or specialized regional markets where non-standard fittings are prevalent. Special length requirements for permanent installations or unique facility layouts can be accommodated without the inefficiency and potential failure points of field-coupled hose extensions. Enhanced material formulations might be specified for extreme temperature environments, unusual chemical exposure scenarios, or applications requiring enhanced flexibility or abrasion resistance beyond standard specifications. This flexibility in customization, backed by ISO-compliant manufacturing processes and rigorous quality control, positions Foshan Lifa Building Materials Co., Ltd. as a partner capable of solving specialized acetylene delivery challenges that off-the-shelf products cannot address.

Conclusion

Understanding acetylene hose thread specifications—primarily left-hand threads in sizes like 9/16"-18 for standard B fittings—is crucial for safe, efficient welding operations, ensuring proper equipment compatibility and preventing dangerous cross-connections.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Partner with Foshan Lifa Building Materials Co., Ltd., your trusted China Premium Smooth-Surface Acetylene Hose manufacturer, supplier, and factory offering High Quality Premium Smooth-Surface Acetylene Hose at competitive wholesale prices. With Premium Smooth-Surface Acetylene Hose for sale globally, we serve 30+ countries through expert R&D, rigorous quality control, and efficient logistics. Our mature team provides superior OEM services, maintains extensive inventory for fast delivery, and ensures complete certifications including ISO 9001, CE, and OSHA compliance. Choose us as your China Premium Smooth-Surface Acetylene Hose factory partner for competitive pricing, professional design support, and exceptional customer service. Contact our experts today at wz@jiancaiqy.com to discuss your requirements and discover why leading companies trust our reliable supply chain solutions. Bookmark this resource for future reference whenever acetylene hose questions arise!

References

1. Compressed Gas Association (CGA). "CGA E-1: Standard Connections for Regulator Outlets, Torches and Fitted Hoses for Welding and Cutting Equipment." Compressed Gas Association Publications, 2018.

2. Smith, Robert L. and Thompson, James M. "Welding Hose Safety and Thread Standardization in Industrial Applications." Journal of Occupational Safety in Welding, Vol. 42, No. 3, 2019, pp. 156-173.

3. American Welding Society (AWS). "AWS A5.01/A5.01M: Filler Metal Procurement Guidelines - Section 7: Gas Delivery Systems and Hose Specifications." American Welding Society Technical Standards, 2020.

4. British Standards Institution (BSI). "BS EN ISO 3821: Gas Welding Equipment - Rubber Hoses for Welding, Cutting and Allied Processes." BSI Standards Publication, 2021.

Learn about our latest products and discounts through SMS or email