- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Best Industrial Grade Pneumatic Wrench Features You Need to Know

Imagine standing on an assembly line where every second counts, wrestling with stubborn bolts that refuse to budge while your productivity targets loom overhead. The right Industrial Grade Pneumatic Wrench transforms this frustrating scenario into smooth, efficient operation. Understanding the essential features of these powerful tools ensures you invest in equipment that delivers consistent performance, reduces operator fatigue, and maximizes your return on investment across automotive, manufacturing, construction, and heavy machinery applications.

Understanding Industrial Grade Pneumatic Wrench Performance Specifications

When selecting an Industrial Grade Pneumatic Wrench for demanding applications, performance specifications serve as the foundation for making informed purchasing decisions. The torque output stands as the most critical specification, typically ranging from 400 Nm for light assembly work to over 2000 Nm for heavy industrial applications. Professional-grade pneumatic impact wrenches utilize air-driven motors that provide consistent high-speed rotations, enabling constant torque delivery that surpasses manual tools and even many electric alternatives. The coupling of an air motor with a planetary gearbox offers substantially faster operation without compromising safety standards required in industrial environments. Operating pressure requirements directly influence tool performance and efficiency. Most industrial pneumatic wrenches operate optimally at 90 pounds per square inch, though heavy-duty models may require higher pressures to achieve maximum torque values. Air consumption rates, measured in liters per minute or cubic feet per minute, determine the compressor capacity needed to maintain continuous operation. Industrial Grade Pneumatic Wrench models designed for assembly lines typically consume between 200 to 350 liters per minute, requiring adequately sized air compressors and distribution systems to prevent performance degradation during extended use. Free speed specifications indicate how quickly the tool rotates without load, typically ranging from 4000 to 8000 RPM for industrial applications. Higher free speeds enable faster bolt engagement and improved productivity in high-volume operations. The relationship between torque, speed, and air consumption creates a performance triangle that must be carefully balanced based on your specific application requirements, whether tightening critical fasteners in aerospace manufacturing or performing routine maintenance on heavy construction equipment.

Torque Control and Precision Features

Advanced Industrial Grade Pneumatic Wrench models incorporate sophisticated torque control mechanisms that prevent over-tightening and under-tightening scenarios that compromise joint integrity. Torque-limited functions coupled with adjustable power regulators allow operators to dial in precise fastening force based on material specifications and engineering requirements. Some industrial models feature multi-position power settings that enable quick adjustment between different torque ranges without tool changes, significantly improving workflow efficiency in diverse assembly operations. The impact mechanism design fundamentally affects torque delivery characteristics and tool longevity. Twin hammer mechanisms provide higher impact frequency and more consistent torque output compared to single hammer designs, making them preferred choices for heavy-duty industrial applications. The hammer and anvil configuration creates the characteristic pulsing action that breaks loose corroded or over-torqued fasteners while the continuous gearing minimizes noise generation and virtually eliminates the hazardous hammering associated with lower-quality impact tools. Shut-off nutrunners automatically disengage when reaching specified torque values, providing critical protection against over-torquing in applications where precision matters most. This feature proves invaluable in industries like automotive manufacturing where warranty claims and component failure rates directly correlate with proper fastening torque. Understanding your application's torque control requirements guides selection between standard impact wrenches suitable for general disassembly work and precision pneumatic torque tools necessary for quality-critical assembly operations.

Material Construction and Durability Standards

Industrial environments subject tools to extreme conditions including temperature fluctuations, chemical exposure, impact loads, and continuous vibration that quickly destroy poorly constructed equipment. Military-grade materials form the foundation of reliable Industrial Grade Pneumatic Wrench construction, with housings typically fabricated from high-strength aluminum alloys, magnesium alloys, reinforced composite materials, or heat-treated steel. Each material offers distinct advantages—aluminum provides excellent strength-to-weight ratios, composite materials reduce operator fatigue during extended use, while steel housings deliver maximum impact resistance for the harshest jobsite conditions. The internal components including gears, bearings, and impact mechanisms must withstand millions of cycles without degradation. Premium manufacturers utilize precision-engineered hardened steel gears, sealed bearing assemblies, and wear-resistant anvil designs that maintain performance specifications throughout the tool's service life. The dual-hammer striking design found in high-performance Industrial Grade Pneumatic Wrench models distributes impact forces more evenly, reducing component stress and extending operational lifespan significantly beyond single-hammer configurations. Surface treatments and protective coatings play crucial roles in corrosion resistance and long-term durability. Industrial-grade tools operating in marine environments, chemical processing facilities, or outdoor construction sites require special attention to corrosion protection. Anodized aluminum housings, powder-coated steel components, and corrosion-resistant fasteners prevent premature failure in challenging environments. The extended motor design incorporating full power delivery mechanisms ensures consistent torque output even as internal components experience normal wear over time, maintaining the ultra-high strength, toughness, and wear resistance that define professional-grade pneumatic tools.

Component Quality and Manufacturing Standards

Manufacturing quality directly impacts tool reliability and operational lifespan in industrial applications. Components manufactured to international standards including ISO 9001, ASTM specifications, and DIN requirements undergo rigorous testing protocols that verify dimensional accuracy, material properties, and performance consistency. The precision fit between moving parts minimizes vibration transmission, reduces noise generation, and improves energy efficiency throughout the tool's operational envelope. Bearing selection and lubrication systems represent critical engineering considerations in Industrial Grade Pneumatic Wrench design. High-quality sealed bearings prevent contamination ingress while maintaining smooth operation under heavy loads. Integrated lubrication systems or user-serviceable lubrication points ensure proper maintenance intervals can be observed, preventing premature wear and maintaining optimal performance characteristics over time. The air motor design significantly influences power delivery characteristics and operational longevity. Rotary vane motors offer excellent power-to-weight ratios and smooth operation, while piston motors provide higher torque capability in compact packages. Understanding the motor type and its maintenance requirements helps establish realistic service intervals and operational cost expectations for your Industrial Grade Pneumatic Wrench investment.

Ergonomic Design and Operator Comfort Features

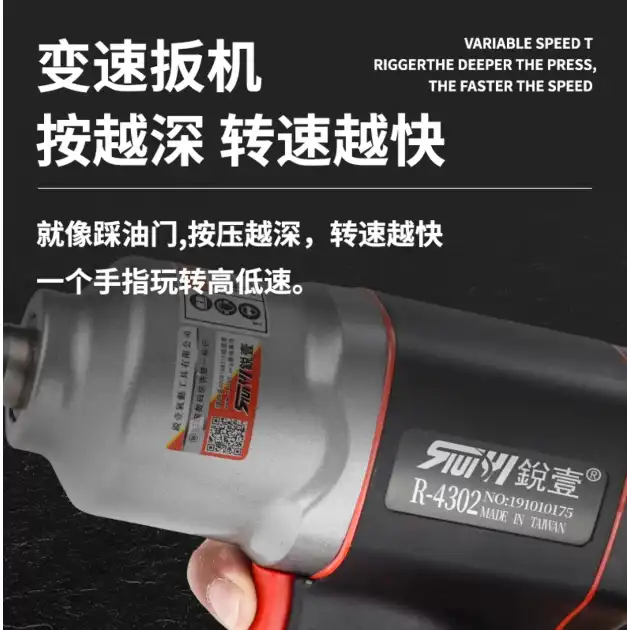

Operator fatigue directly impacts productivity, safety, and quality in industrial operations requiring repetitive tool use throughout extended shifts. The ergonomic handle design incorporating soft rubber grips provides comfortable holding surfaces that reduce hand strain and improve control precision during critical fastening operations. Weight distribution throughout the tool body affects balance and maneuverability—well-designed Industrial Grade Pneumatic Wrench models position the center of gravity near the grip area, minimizing the moment forces that cause arm fatigue during overhead work or extended horizontal operation. Vibration dampening technology represents a crucial health and safety consideration for tools used in high-volume production environments. Excessive vibration exposure contributes to hand-arm vibration syndrome and other repetitive stress injuries that affect operator wellbeing and workforce availability. Industrial-grade pneumatic tools meeting low vibration specifications below 2.5 meters per second squared comply with occupational health standards and protect long-term operator health while maintaining the power output necessary for demanding applications. Trigger design and placement affect operational control and reduce accidental activation risks in busy work environments. Progressive triggers that vary power output based on operator pressure provide additional control for delicate operations, while simple on-off triggers maximize simplicity in straightforward assembly applications. Some Industrial Grade Pneumatic Wrench models incorporate forward-reverse mechanisms integrated into the handle design, enabling one-handed operation changes that improve workflow efficiency and reduce the time spent repositioning hands during repetitive fastening cycles.

Advanced Ergonomic Innovations

The 360-degree universal air inlet connector represents a significant ergonomic advancement that prevents air hose tangling and reduces connector wear during normal operation. This swivel connection allows the tool to rotate freely without twisting the supply hose, preventing the frustrating hose management problems that interrupt workflow and create tripping hazards in congested work areas. The rotational freedom also reduces the torque forces transmitted through the air hose, extending hose life and reducing replacement costs over the tool's operational lifetime. Auxiliary handles available on larger Industrial Grade Pneumatic Wrench models provide additional control points for two-handed operation during high-torque applications. These secondary grip points distribute reaction forces across both arms, significantly reducing operator fatigue when working with fasteners requiring maximum torque output. The adjustable positioning of auxiliary handles accommodates different operator preferences and work angles, improving versatility across diverse application scenarios. Noise level specifications affect both operator comfort and regulatory compliance in industrial environments. While pneumatic tools inherently generate operational noise, advanced muffler designs and optimized air exhaust routing reduce sound output to acceptable levels for extended exposure. Industrial Grade Pneumatic Wrench models featuring noise levels around 85 decibels balance performance requirements with hearing protection considerations, though hearing protection remains recommended for all pneumatic tool operations regardless of manufacturer specifications.

Air System Requirements and Operational Efficiency

Successful Industrial Grade Pneumatic Wrench operation depends entirely on properly designed and maintained compressed air systems. Air compressor capacity must exceed tool consumption requirements by substantial margins to maintain consistent pressure during continuous operation. A wrench consuming 280 liters per minute requires a compressor rated for at least 350 liters per minute to account for system losses, simultaneous tool operation, and pressure recovery time between usage cycles. Undersized compressor systems result in pressure drops that directly reduce torque output and extend cycle times, negating the productivity advantages of pneumatic tools. Air quality significantly impacts tool performance and longevity in industrial pneumatic systems. Moisture contamination causes internal corrosion, washes away lubricants, and freezes in valve assemblies during cold weather operation. Particulate contamination accelerates wear on precision components including bearings, seals, and air motor vanes. Properly designed compressed air systems incorporate filtration, pressure regulation, and lubrication equipment positioned close to tool connection points, ensuring clean, dry, properly lubricated air reaches the Industrial Grade Pneumatic Wrench throughout every operating cycle. The air inlet size specification, typically ranging from 1/4 inch to 1/2 inch NPT for industrial wrenches, must be matched with appropriately sized supply hoses and quick-connect fittings. Undersized air supply components create pressure restrictions that starve the tool of necessary air volume, similar to compressor capacity limitations. Industrial operations benefit from establishing standardized air supply configurations that support the most demanding tools in the facility, preventing the productivity losses and equipment damage caused by inadequate pneumatic infrastructure.

Maintenance Requirements and Service Intervals

Regular maintenance preserves Industrial Grade Pneumatic Wrench performance and prevents costly downtime in production environments. Daily pre-use inspections should verify air supply pressure, check for air leaks at connections, and confirm proper lubrication levels in inline oilers. Tools without automatic lubrication systems require manual oil addition through designated ports before each use or at specified intervals based on operating hours. Using manufacturer-recommended pneumatic tool oil prevents varnish buildup and ensures proper lubrication film thickness for moving components. Weekly maintenance intervals should include thorough cleaning of air inlet filters, inspection of exhaust ports for obstructions, and verification of all fasteners and retaining hardware. The 360-degree universal air inlet connector requires periodic inspection for wear or damage that might cause air leaks or restrict supply flow. Any unusual noise, vibration, or performance changes warrant immediate investigation to prevent minor issues from escalating into major component failures requiring expensive repairs or complete tool replacement. Major service intervals typically occur at 500 to 1000 operating hours depending on application severity and operating environment. Complete disassembly, cleaning, inspection, and component replacement restore Industrial Grade Pneumatic Wrench units to like-new performance specifications. Establishing preventive maintenance schedules based on actual operating hours rather than calendar intervals optimizes maintenance resource allocation and minimizes unexpected failures that disrupt production schedules. Maintaining detailed service records supports warranty claims and provides valuable data for total cost of ownership calculations when evaluating future equipment purchases.

Conclusion

Selecting the optimal Industrial Grade Pneumatic Wrench requires balancing torque specifications, material construction quality, ergonomic features, and air system compatibility with your specific application demands and operational environment.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Partner with Foshan Lifa Building Materials Co., Ltd., your trusted China Industrial Grade Pneumatic Wrench manufacturer, China Industrial Grade Pneumatic Wrench supplier, and China Industrial Grade Pneumatic Wrench factory offering competitive Industrial Grade Pneumatic Wrench price and High Quality Industrial Grade Pneumatic Wrench solutions. As a leading China Industrial Grade Pneumatic Wrench wholesale provider serving over 30 countries, we deliver ISO-compliant products backed by extensive inventory, rigorous quality control, and flexible OEM/ODM services. Our experienced R&D team and 50,000 square meter manufacturing facility ensure you receive Industrial Grade Pneumatic Wrench for sale that meets international standards including ISO 9001, CE, and ATEX certifications. Contact us at wz@jiancaiqy.com for expert guidance, custom solutions, and exceptional service that transforms your industrial fastening operations.

References

1. "Pneumatic Torque Wrenches in Industrial Applications" by Maxwell J. Henderson, Journal of Industrial Engineering Technology, 2023

2. "Material Science and Tool Durability in Pneumatic Impact Systems" by Dr. Sarah Chen and Prof. Robert Martinez, International Journal of Manufacturing Engineering, 2024

3. "Ergonomic Design Principles for Industrial Hand Tools" by Industrial Safety Research Institute, Occupational Health and Safety Standards Publication, 2022

4. "Compressed Air System Design for Optimal Pneumatic Tool Performance" by Thomas Anderson, Pneumatic Systems Engineering Handbook, 2023

5. "Torque Control Technologies in Modern Assembly Operations" by Jennifer Williams, Manufacturing Process Optimization Quarterly, 2024

Learn about our latest products and discounts through SMS or email