- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Choose a Heavy-Duty Lithium-Ion Wrench: Key Criteria?

Picture this: you're on a construction site, facing a stubborn rusted bolt that refuses to budge. Your standard tools aren't cutting it, and time is running out. This is where choosing the right Heavy-Duty Lithium-Ion Wrench becomes critical. The market offers countless options, but selecting one that combines sufficient torque output, reliable battery performance, and durable construction can mean the difference between smooth operations and costly downtime. Understanding the key criteria for choosing a Heavy-Duty Lithium-Ion Wrench ensures you invest in a tool that delivers consistent power, extended runtime, and professional-grade reliability for demanding industrial applications.

Understanding Heavy-Duty Lithium-Ion Wrench Torque Requirements

Matching Torque Output to Your Application Needs

When evaluating a Heavy-Duty Lithium-Ion Wrench, torque specifications stand as the most fundamental performance indicator. Professional applications demand different torque levels depending on the task complexity and fastener resistance. Standard automotive maintenance typically requires torque outputs between 200 to 400 Newton meters, which handles routine bolt tightening and loosening operations effectively. However, industrial environments involving heavy machinery, structural steel assembly, or mining equipment necessitate significantly higher torque capabilities, often exceeding 500 to 800 Newton meters or more. The distinction between breakaway torque and fastening torque becomes crucial here. Breakaway torque refers to the initial force required to loosen a seized or rusted fastener, while fastening torque relates to the controlled tightening force. A quality Heavy-Duty Lithium-Ion Wrench should deliver adequate breakaway torque to handle the toughest applications while offering precise control for accurate fastening work. Understanding your specific torque requirements prevents both tool underperformance and potential damage to fasteners or workpieces from excessive force application.

Impact Mechanism Technology in Modern Wrenches

The internal hammering mechanism distinguishes impact wrenches from conventional power tools and directly influences their effectiveness in heavy-duty applications. Modern Heavy-Duty Lithium-Ion Wrench designs incorporate advanced hammer and anvil systems that deliver rapid bursts of rotational force, measured in impacts per minute. This mechanism allows the tool to generate substantial torque without transferring excessive strain to the operator's wrist or arm, making extended use more comfortable and sustainable. Fifth-generation brushless motor technology has revolutionized impact wrench performance by eliminating friction-generating carbon brushes, resulting in spark-free operation that enhances safety in sensitive environments while delivering longer-lasting power. The brushless motor design also contributes to improved energy efficiency, extending battery runtime and reducing maintenance requirements compared to traditional brushed motors. When selecting a Heavy-Duty Lithium-Ion Wrench, prioritize models featuring brushless motors combined with tungsten steel rotating shafts, as these components ensure the tool remains sturdy and durable even under continuous heavy-duty operation across various industrial settings.

Battery Performance and Power Management

Lithium-Ion Battery Advantages Over Alternative Technologies

The battery system represents the heart of any cordless Heavy-Duty Lithium-Ion Wrench, and lithium-ion technology has established itself as the superior choice for professional applications. Compared to older nickel-cadmium or nickel-metal hydride batteries, lithium-ion cells offer significantly higher energy density, meaning they can store more power in a smaller, lighter package. This translates to extended runtime capabilities that allow professionals to complete more work on a single charge, reducing interruptions and maintaining workflow efficiency. Lithium-ion batteries also feature minimal self-discharge rates, retaining their charge during storage periods much better than previous battery technologies. The absence of memory effect in lithium-ion cells means users can recharge the battery at any charge level without compromising its long-term capacity or performance. Professional-grade Heavy-Duty Lithium-Ion Wrench models typically support battery lifecycles exceeding 1000 charge cycles, ensuring years of reliable service before replacement becomes necessary. Quick-charging capability has become standard in modern lithium-ion systems, with many models achieving full charge in approximately one hour, minimizing downtime and maximizing productivity across demanding work environments.

Voltage Considerations and Runtime Balance

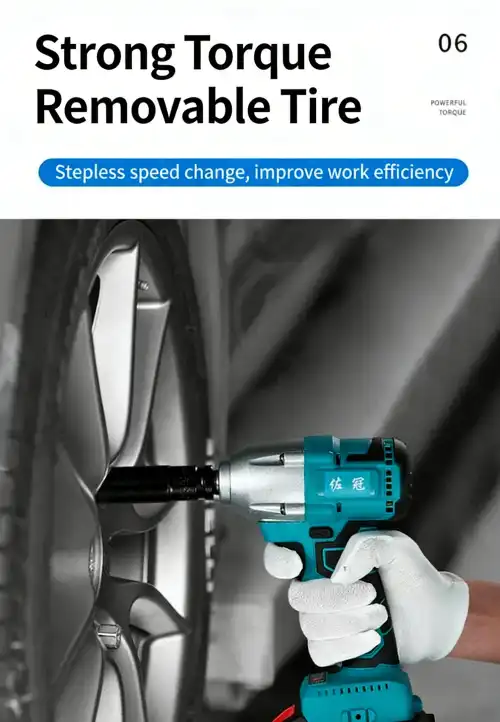

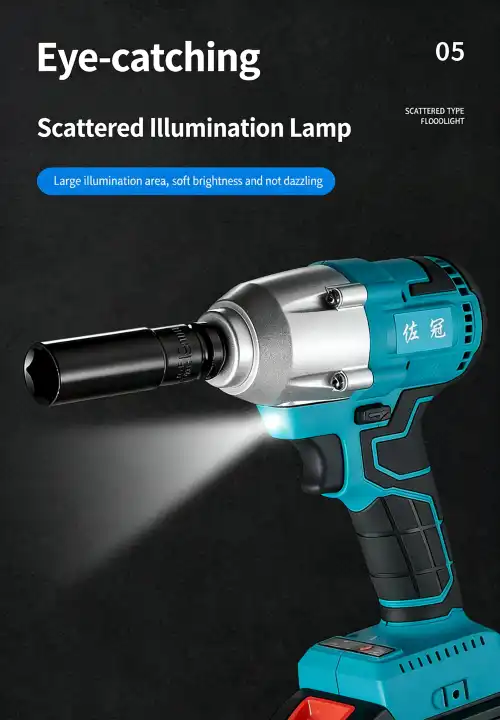

Battery voltage directly correlates with the power output capabilities of a Heavy-Duty Lithium-Ion Wrench, making voltage selection a critical decision factor. The market predominantly features 18-volt and 20-volt platforms, which have become industry standards for heavy-duty applications. These voltage levels strike an optimal balance between delivering sufficient power for challenging tasks and maintaining reasonable tool weight and battery size. Higher voltage systems provide stronger torque output and maintain consistent performance even as the battery depletes, whereas lower voltage options like 12-volt systems, while more compact and lightweight, may struggle with heavy-duty applications or extended use scenarios. Battery capacity, measured in ampere-hours, determines how long the tool operates before requiring recharge. A 4.0Ah battery generally provides adequate runtime for most professional applications, supporting continuous operation throughout typical work shifts. Models featuring detachable battery systems with built-in lighting functions offer practical convenience, allowing the battery to serve dual purposes while the integrated LED illuminates work areas in low-light conditions. Stepless speed regulation controlled through sensitive button mechanisms enables operators to adjust the Heavy-Duty Lithium-Ion Wrench speed precisely by varying pressure on the switch, effectively improving work efficiency while preventing damage to delicate fasteners or materials.

Essential Design Features and Ergonomics

Motor Technology and Drive Size Selection

The motor type fundamentally impacts the overall performance, longevity, and maintenance requirements of a Heavy-Duty Lithium-Ion Wrench. Brushless motors have become the professional standard due to their superior efficiency, extended lifespan, and reduced maintenance needs compared to brushed motor alternatives. A brushless motor design typically lasts three times longer than conventional brushed motors while consuming approximately thirty percent less power, maximizing both tool longevity and battery efficiency. The spark-free operation inherent to brushless technology also enhances safety in environments where combustible materials or gases may be present. Drive size represents another crucial specification that determines socket compatibility and application suitability. The most common drive sizes include three-eighths inch for light-duty applications, one-half inch for general-purpose automotive and construction work, and three-quarters inch for heavy-duty industrial applications. The one-half inch drive has emerged as the optimal size for most professional applications, offering the best balance between versatility, socket availability, and adequate strength for demanding tasks. A quality Heavy-Duty Lithium-Ion Wrench should feature a reliable socket attachment system, typically utilizing either a friction ring or detent pin mechanism to securely hold sockets during operation while allowing quick socket changes without additional tools.

Control Features and Operational Versatility

Variable speed control and multiple power settings distinguish professional-grade Heavy-Duty Lithium-Ion Wrench models from basic consumer tools. A variable speed trigger allows operators to precisely control rotational speed and consequently the impact rate, enabling greater precision across diverse tasks and preventing overtightening or damage to sensitive fasteners. Advanced models offer multiple speed or impact modes, such as low, medium, high, or automatic settings, providing flexibility to match tool performance to specific job requirements. Forward and reverse mode switches facilitate easy direction changes, allowing operators to handle different working conditions efficiently without manual tool adjustments. This becomes particularly valuable when working in confined spaces or when rapid switching between tightening and loosening operations is necessary. Integrated LED lighting systems have become essential features in modern Heavy-Duty Lithium-Ion Wrench designs, illuminating the work area to improve visibility in poorly lit environments such as engine compartments, under-vehicle spaces, or interior industrial machinery. The combination of adjustable torque settings, multi-functional operational modes, and convenient features like built-in lighting transforms a Heavy-Duty Lithium-Ion Wrench from a simple power tool into a versatile, efficient solution for professional tradespeople and industrial applications.

Durability and Build Quality Considerations

Construction Materials and Weather Resistance

Professional applications demand Heavy-Duty Lithium-Ion Wrench construction that withstands harsh environmental conditions and physical abuse common on job sites. Premium models feature impact-resistant housing constructed from durable materials designed to survive accidental drops, vibration exposure, and rough handling throughout daily use. Weather and impact-resistant construction becomes particularly important for outdoor applications or environments exposed to moisture, dust, or temperature extremes. Tools with proper IP rating protection against water and dust ingress ensure reliable operation across varied working conditions, from construction sites to automotive repair shops to industrial facilities. The internal components, particularly the tungsten steel rotating shaft, must exhibit exceptional strength and wear resistance to maintain precision and performance throughout the tool's service life. Quality Heavy-Duty Lithium-Ion Wrench models incorporate thermal protection systems that prevent motor or battery overheating during extended heavy use, significantly extending component lifespan and preventing premature failure. Electronic cell protection mechanisms safeguard lithium-ion batteries against overcharge, over-discharge, and extreme temperature exposure, preserving battery health and maximizing the investment value. Overload protection features automatically shut down the tool when encountering excessive resistance, preventing damage to the motor and internal components while protecting operators from potential tool failure.

Warranty Coverage and Certification Standards

Warranty terms and industry certifications provide important indicators of a Heavy-Duty Lithium-Ion Wrench quality and manufacturer confidence. Reputable manufacturers typically offer warranty coverage ranging from one to three years, with professional-grade models often featuring extended protection periods. A comprehensive warranty should cover manufacturing defects, component failures, and performance issues under normal operating conditions, providing peace of mind and protecting the investment. International certification compliance demonstrates that the Heavy-Duty Lithium-Ion Wrench meets rigorous quality and safety standards established by recognized organizations. ISO 9001:2015 Quality Management System certification indicates the manufacturer implements systematic quality control processes throughout production, ensuring consistent product quality and reliability. CE Certification confirms the tool meets European Union safety, health, and environmental protection requirements, while RoHS Compliance verifies the absence of hazardous substances in the manufacturing process. Products adhering to ASTM and DIN international standards ensure quality specifications meet the rigorous requirements demanded by global markets. These certifications not only validate product quality but also ensure the Heavy-Duty Lithium-Ion Wrench performs safely and reliably across diverse professional applications, from manufacturing assembly lines and construction sites to automotive repair shops and industrial equipment servicing operations.

Conclusion

Selecting the right Heavy-Duty Lithium-Ion Wrench requires careful evaluation of torque capabilities, battery performance, motor technology, and build quality to ensure the tool meets your specific professional demands effectively.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

As a China Heavy-Duty Lithium-Ion Wrench manufacturer with extensive experience in building hardware supply, Foshan Lifa Building Materials Co., Ltd. offers exceptional value for professional tool procurement. Our China Heavy-Duty Lithium-Ion Wrench factory produces high-quality tools compliant with ISO9001, ASTM, and DIN international standards, ensuring reliable performance across demanding industrial applications. As a trusted China Heavy-Duty Lithium-Ion Wrench supplier, we maintain extensive inventory for immediate shipment, competitive pricing structures, and flexible OEM services tailored to market-specific requirements. Our in-house design team delivers custom solutions while our experienced staff provides expert guidance throughout the procurement process. Whether you need China Heavy-Duty Lithium-Ion Wrench wholesale quantities or High Quality Heavy-Duty Lithium-Ion Wrench for specific projects, we offer Heavy-Duty Lithium-Ion Wrench for sale at competitive Heavy-Duty Lithium-Ion Wrench price points without compromising quality. With products successfully serving more than thirty countries globally and supporting renowned clients including China State Construction Engineering Group and China Railway Construction Group, we have established ourselves as a reliable supply chain partner. Our commitment to "Ingenious Manufacturing, Global Sharing" ensures every Heavy-Duty Lithium-Ion Wrench delivers superior performance backed by rigorous quality control and exceptional customer service. Contact us today at wz@jiancaiqy.com to discuss your Heavy-Duty Lithium-Ion Wrench requirements and discover how our professional team can support your business success.

References

1. "Cordless Impact Wrench Technology and Performance Standards" - Industrial Tools Research Institute, Professional Power Tools Division

2. "Lithium-Ion Battery Applications in Heavy-Duty Power Tools" - Battery Technology Association, Industrial Applications Committee

3. "Torque Specifications and Safety Standards for Impact Wrenches" - International Standards Organization, Tool Safety Technical Committee

4. "Brushless Motor Technology in Professional Power Tools" - Manufacturing Engineering Society, Electric Motor Research Group

5. "Quality Management Systems for Building Hardware Production" - Global Construction Equipment Standards Council, Quality Assurance Department

Learn about our latest products and discounts through SMS or email