- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Does an Electric Woodworking Trimmer Improve Workflow?

Picture this: You're racing against a deadline, manually sanding edges for hours, your arms aching, only to realize the finish is inconsistent and you've wasted valuable production time. This frustrating scenario plagues woodworkers daily, draining profitability and creative energy. An electric woodworking trimmer transforms this exhausting manual labor into swift, precision work by delivering consistent high-speed cuts that reduce project completion times by up to 60 percent while maintaining professional-grade accuracy across every edge, groove, and profile.

Understanding Electric Woodworking Trimmer Technology and Efficiency

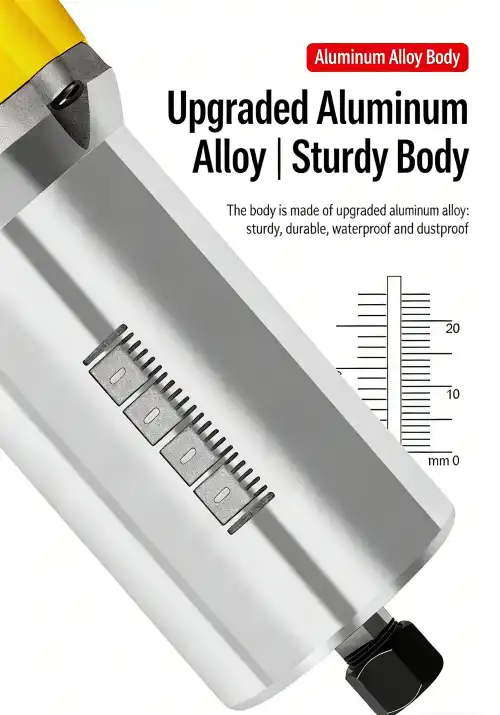

The electric woodworking trimmer represents a significant technological advancement in precision carpentry equipment, combining compact design with industrial-grade performance capabilities. These specialized power tools have revolutionized how professionals and craftsmen approach edge finishing, decorative profiling, and intricate woodwork detailing. Unlike their larger router counterparts, electric woodworking trimmers are engineered specifically for one-handed operation, offering superior maneuverability in confined spaces while maintaining the power necessary for demanding applications. The fundamental design incorporates a high-speed motor directly coupled to a collet system that secures various cutting bits, enabling woodworkers to execute operations ranging from simple edge rounding to complex pattern work with remarkable consistency. Modern electric woodworking trimmer models feature motors ranging from 500W to 1200W, generating rotational speeds between 25,000 and 35,000 RPM. This combination of substantial power and extreme velocity allows the cutting bit to slice through wood fibers cleanly rather than tearing them, resulting in smoother finishes that require minimal post-processing sanding. The compact form factor, typically weighing between 1.5 and 3.5 kilograms, reduces operator fatigue during extended use while improving control over delicate operations. Professional-grade electric woodworking trimmers incorporate precision depth adjustment mechanisms calibrated in millimeter increments, enabling craftsmen to achieve repeatable results across multiple workpieces. This level of accuracy proves particularly valuable in furniture manufacturing and cabinetry, where consistency across dozens or hundreds of components directly impacts assembly quality and final product aesthetics.

Core Components Driving Workflow Enhancement

The motor assembly serves as the performance foundation of any electric woodworking trimmer, with copper-wound motors offering superior heat dissipation and longevity compared to aluminum alternatives. Advanced models incorporate electronic speed control systems that maintain constant RPM under varying load conditions, preventing slowdown when encountering denser wood sections or knots. This consistent performance eliminates the workflow interruptions caused by stalling or burning, allowing operators to maintain steady feed rates throughout production runs. The collet system, typically accommodating 1/4-inch or 6mm shank bits, utilizes precision-ground components that minimize runout and vibration. Reduced vibration translates directly to improved cut quality, extended bit life, and decreased operator fatigue during prolonged operations. Transparent base plates represent another crucial design element that significantly impacts workflow efficiency. Unlike opaque bases that obscure the cutting area, transparent acrylic or polycarbonate bases provide unobstructed sightlines to the workpiece, enabling operators to follow layout lines accurately without constant repositioning or measurement verification. This visibility advantage reduces errors, minimizes material waste, and accelerates project completion. Many professional-grade electric woodworking trimmers feature adjustable base plates with graduated scales, allowing quick setup for common depths without requiring measurement tools. The combination of visual feedback and rapid adjustment capabilities streamlines the workflow by eliminating the setup delays that accumulate across multiple operations throughout a production day.

Power and Speed Specifications Impact on Productivity

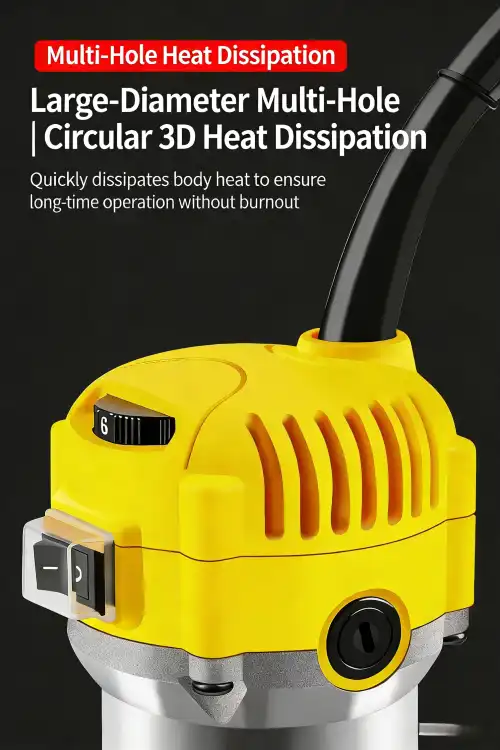

The relationship between motor power, rotational speed, and workflow efficiency cannot be overstated when evaluating electric woodworking trimmer performance. A 630W motor generating 35,000 RPM delivers approximately 140 percent more cutting efficiency than a 500W model operating at 30,000 RPM when processing hardwoods like oak or maple. This performance difference translates directly to reduced pass requirements, faster project completion, and improved surface finishes that require less secondary processing. High-speed operation also enables the use of smaller diameter bits for intricate detail work, expanding the range of decorative profiles and design options available to craftsmen without requiring additional specialized equipment. Thermal management systems play a critical role in maintaining consistent performance during extended workflow sessions. Electric woodworking trimmers equipped with efficient air venting channels prevent motor overheating that causes performance degradation and premature component failure. Professional models incorporate replaceable carbon brushes that maintain optimal electrical contact as they wear, ensuring consistent power delivery throughout the tool's operational lifespan. This reliability eliminates the unexpected downtime that disrupts workflow schedules and project timelines. When equipped with proper thermal protection, a quality electric woodworking trimmer can operate continuously for hours during high-volume production runs, supporting workflow demands that would quickly overwhelm lesser tools or manual methods.

Operational Advantages for Various Woodworking Applications

Electric woodworking trimmers excel across diverse applications, each benefiting from specific tool characteristics that enhance workflow efficiency. In furniture manufacturing environments, these tools handle edge profiling operations that would require multiple passes with hand planes or considerable time with orbital sanders. The electric woodworkingrimmer completes roundover, chamfer, and ogee profiles in single passes, reducing processing time per component from minutes to seconds. This acceleration compounds across production runs involving hundreds of components, transforming operations that once required days into tasks completed within single shifts. The consistency achieved through power tool operation also eliminates the variability inherent in hand tool work, ensuring that every component meets dimensional specifications without requiring individual quality checks. Cabinet making represents another application where electric woodworking trimmers dramatically improve workflow efficiency. Door edge profiling, drawer face detailing, and decorative panel work all benefit from the precision and speed these tools provide. When equipped with appropriate guide systems, electric woodworking trimmers execute perfectly straight cuts along cabinet sides for hinge mortises, eliminating the layout time and careful chisel work traditional methods require. The roller guide attachments included with many models follow curved workpiece edges accurately, enabling efficient production of arched cabinet doors and decorative elements without requiring expensive template systems. This versatility reduces equipment investment requirements while maintaining the production flexibility necessary to accommodate custom orders and design variations.

Edge Treatment and Profile Creation

Edge treatment operations constitute perhaps the most common application for electric woodworking trimmers, encompassing tasks from simple easing operations that prevent splinter formation to elaborate decorative profiles that enhance aesthetic appeal. A basic roundover operation that might require five minutes of careful hand work with sandpaper and sanding blocks takes approximately fifteen seconds with an electric woodworking trimmer equipped with an appropriate radius bit. This dramatic time reduction enables craftsmen to elevate the finish quality of even basic projects without adding significant labor costs. The crisp, uniform edges produced by router bits also convey superior craftsmanship compared to the slightly irregular results typical of hand finishing methods, potentially commanding premium pricing in competitive markets. Complex multi-step profiles that combine coves, beads, and flats challenge even experienced craftsmen when executed manually, requiring careful layout, multiple tool changes, and constant verification to maintain consistency. Electric woodworking trimmers simplify this process dramatically by enabling single-pass execution with appropriately shaped bits. While complex profile bits command premium prices compared to basic shapes, the workflow efficiency they provide typically justifies the investment within the first few projects. The ability to execute consistent complex profiles also opens design possibilities that would prove impractical with manual methods, enabling craftsmen to differentiate their work and access higher-value market segments.

Groove Cutting and Joinery Operations

Groove cutting for decorative inlays, panel installations, and cable management represents another application where electric woodworking trimmers significantly enhance workflow efficiency. These operations demand precise depth control and straight execution over extended distances, requirements that prove challenging with hand tools but straightforward with power equipment. When guided by straight edges or fences, electric woodworking trimmers cut grooves with dimensional consistency that enables trouble-free panel installation without requiring fitting adjustments. This accuracy reduces assembly time while improving final product quality through tighter tolerances and cleaner appearance. The high rotational speed of electric woodworking trimmer bits also produces smooth groove bottoms that often require no additional finishing, unlike the torn fibers and surface irregularities common with hand-cut grooves. Joinery applications including sliding dovetails, tongue-and-groove connections, and box joints benefit substantially from electric woodworking trimmer capabilities when appropriate jigs guide the cutting process. While these jigs represent additional equipment investment, they enable rapid production of precision joints that would require considerable skill and time to execute manually. A craftsman might spend thirty minutes carefully cutting a single sliding dovetail joint with hand tools, while the same operation takes approximately two minutes with an electric woodworking trimmer and appropriate jig. This efficiency transformation makes complex joinery practical for production work rather than limiting it to showcase pieces where extended labor investment can be justified.

Integration with Guide Systems and Accessories

The workflow efficiency of electric woodworking trimmers multiplies when integrated with appropriate guide systems and accessories that enhance accuracy while expanding capability. Straight edge guides transform freehand operations into precisely controlled cuts, eliminating the steady-hand requirements that limit manual tool effectiveness. These guides, typically adjustable for various offset distances, enable rapid setup for operations like cabinet hinge mortising where consistent positioning relative to edges proves critical. The electric woodworking trimmer follows the guide effortlessly, producing identical results across dozens of components without the concentration fatigue that accumulates during repetitive manual work. This consistency proves particularly valuable in production environments where interchangeable components must mate perfectly during assembly. Roller guide attachments represent another accessory category that dramatically enhances electric woodworking trimmer versatility. These guides feature small wheels that roll along curved workpiece edges, maintaining consistent offset distances while accommodating radius variations. This capability enables efficient edge profiling of arched components, circular tabletops, and irregular organic shapes without requiring expensive custom templates. The roller guide essentially converts the workpiece itself into the template, eliminating the design and fabrication time traditional template-guided routing demands. For custom woodworking operations where each piece features unique curves, this flexibility proves invaluable, enabling craftsmen to accept projects that would otherwise prove uneconomical due to template requirements.

Template and Pattern Routing Capabilities

Template routing represents one of the most powerful workflow enhancement techniques available to woodworkers, enabling rapid production of complex shapes with consistent dimensional accuracy. Electric woodworking trimmers excel in template work due to their compact size and superior visibility compared to full-size routers. The operator positions the template against the workpiece, then guides the electric woodworking trimmer around the template perimeter using a flush-trim or pattern bit. The bearing on the bit rides against the template edge, transferring the template shape to the workpiece with accuracy limited only by the bearing precision and operator steadiness. This technique enables craftsmen to produce dozens of identical components from a single carefully crafted template, amortizing the template development time across the entire production run. Pattern routing extends template concepts by using one finished component as the pattern for subsequent pieces. This approach proves particularly valuable when producing replacement components for restoration work or creating matched sets where slight variations would prove noticeable. The electric woodworking trimmer equipped with a pattern bit replicates every detail of the original component, including curves, cutouts, and edge profiles that would prove extremely challenging to reproduce through measurement and manual cutting methods. This capability enables small-scale production of custom components without requiring the expensive tooling and setup that traditional manufacturing methods demand, opening market opportunities that would otherwise remain inaccessible to independent craftsmen and small workshops.

Specialized Bits Expanding Functional Range

The functional range of electric woodworking trimmers extends far beyond basic edge profiles through the availability of specialized cutting bits designed for specific applications. Keyhole bits create the recessed slots necessary for wall-mounting hardware, executing operations in seconds that would require careful drilling and chisel work manually. Flush-trim bits enable precise size reduction of edge-banded panels and laminated surfaces, ensuring perfect alignment between substrate and facing materials. Core box bits produce the rounded bottom grooves common in decorative moldings and fluting operations. The extensive bit variety available in 1/4-inch shank configurations ensures that electric woodworking trimmers can address virtually any profile or forming requirement craftsmen encounter. High-quality carbide-tipped bits maintain sharp cutting edges through thousands of linear feet of cutting, providing consistent performance throughout extended production runs. The upfront investment in premium bits pays dividends through superior surface finishes that require minimal secondary processing, extended service life that reduces replacement frequency, and reduced loading that minimizes motor strain and heat generation. When properly maintained through periodic cleaning and occasional sharpening, quality bits support efficient workflow for years, making them essential components of professional woodworking operations. The electric woodworking trimmer becomes exponentially more valuable as the bit collection expands, ultimately representing a complete edge-forming system rather than a single-purpose tool.

Ergonomic Design Reducing Operator Fatigue

Physical comfort during extended operations directly impacts workflow productivity, with operator fatigue leading to reduced accuracy, slower work pace, and increased error rates. Electric woodworking trimmers address this challenge through ergonomic designs that minimize the physical stress associated with precision handheld operations. Rubber-coated base grips provide secure purchase without requiring excessive grip pressure, reducing hand and forearm fatigue during prolonged use. The compact dimensions and balanced weight distribution enable natural tool positioning that avoids the awkward postures contributing to shoulder and back strain. These ergonomic advantages allow operators to maintain efficient work pace throughout full production shifts rather than experiencing the productivity decline typical with physically demanding manual methods or poorly designed power tools. The lightweight construction of modern electric woodworking trimmers, typically ranging from 1.5 to 3 kilograms, proves particularly beneficial during vertical and overhead operations where tool weight multiplies operator fatigue. Cabinet installations, door hanging operations, and architectural millwork often require extended periods of overhead routing that would prove exhausting with heavier full-size routers. The electric woodworking trimmer handles these applications comfortably, enabling craftsmen to maintain quality standards without the physical stress that compromises concentration and accuracy. This capability proves especially valuable in renovation and remodeling contexts where working conditions often involve awkward access and cramped spaces that challenge larger equipment.

Vibration Reduction for Extended Operation

Vibration represents a significant ergonomic concern with handheld power tools, with extended exposure contributing to hand-arm vibration syndrome and related health issues. Modern electric woodworking trimmers incorporate design features that minimize vibration transmission to the operator, including precision-balanced motor assemblies, vibration-dampening mounting systems, and optimized housing materials that absorb rather than transmit operational vibration. These refinements enable comfortable extended operation without the numbness and discomfort associated with older tool designs or low-quality equipment. The health and comfort advantages translate directly to sustained productivity and career longevity for professional woodworkers who depend on their physical capabilities for livelihood. Proper bit selection and maintenance also impact vibration levels significantly, with dull or damaged bits generating excessive vibration and degraded cut quality. Sharp, properly balanced bits cut cleanly with minimal resistance, reducing the forces transmitted through the electric woodworking trimmer to the operator's hands. Regular inspection and timely bit replacement therefore serve dual purposes, maintaining both cut quality and operator comfort. When combined with ergonomic tool design, proper bit management creates working conditions that support efficient, comfortable operation throughout demanding production schedules. This attention to the human factors of woodworking operations distinguishes professional approaches from hobbyist practices, ultimately impacting both productivity and long-term operational sustainability.

Dust Management and Workspace Organization

Effective dust management contributes substantially to workflow efficiency by maintaining clear visibility of cut lines, reducing cleanup requirements, and creating healthier working conditions. While compact electric woodworking trimmers typically lack the integrated dust collection ports found on larger routers, their operation generates less airborne debris due to lower material removal rates and compact cutting zones. Strategic positioning of shop vacuum hoses near the cutting area captures much of the generated dust, particularly when working with soft woods that produce fluffy shavings rather than fine dust. This proactive dust control maintains workspace organization and reduces the frequent cleanup interruptions that fragment workflow and reduce productivity. Organized bit storage systems further enhance workflow efficiency by eliminating the time wasted searching for specific profiles or bits. Dedicated router bit cases with labeled compartments enable rapid bit selection and change, reducing setup time between operations. Many craftsmen adopt color-coding systems or size-based organization schemes that enable intuitive bit location without requiring detailed inventory knowledge. The seemingly minor efficiency gained through organized storage compounds throughout production days involving multiple bit changes, ultimately representing meaningful time savings. When combined with the operational advantages of the electric woodworking trimmer itself, these workflow optimization practices create comprehensive efficiency improvements that dramatically impact productivity and profitability.

Conclusion

Electric woodworking trimmers revolutionize carpentry workflows through exceptional speed, precision, and versatility that manual methods cannot match. By dramatically reducing processing time while maintaining superior consistency across components, these power tools enable craftsmen to complete more projects profitably while elevating quality standards. The combination of powerful motors, ergonomic design, and extensive accessory compatibility makes electric woodworking trimmers indispensable for modern woodworking operations seeking competitive advantages through operational efficiency.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Foshan Lifa Building Materials Co., Ltd. stands as your trusted China electric woodworking trimmer manufacturer and China electric woodworking trimmer supplier, delivering high-quality electric woodworking trimmer for sale backed by comprehensive quality certifications including ISO9001, ASTM, and DIN compliance. Our expertise as a leading China electric woodworking trimmer factory enables us to provide competitive electric woodworking trimmer prices combined with flexible OEM/ODM customization services tailored to diverse global market requirements. With our experienced professional team skilled in R&D design, international quality certification, and efficient supply chain management, we guarantee reliable delivery of high-quality electric woodworking trimmers to over 30 countries across South America, Europe, Australia, the Middle East, and Southeast Asia.

Our state-of-the-art manufacturing facilities in Foshan implement strict quality control throughout production, ensuring every electric woodworking trimmer meets rigorous performance standards. We maintain extensive inventory for immediate shipment, eliminating the delays that disrupt your business operations. Whether you're an international distributor, engineering contractor, or furniture manufacturer, our China electric woodworking trimmer wholesale programs deliver the cost advantages and product quality your business demands. Partner with us to access not just premium products, but comprehensive support including design consultation, technical guidance, and responsive customer service throughout every stage of collaboration. Contact us today at wz@jiancaiqy.com to discuss your electric woodworking trimmer requirements and discover how our manufacturing excellence and customer commitment can strengthen your supply chain while reducing procurement costs.

References

1. Woodworking Machinery Industry Association. Precision Routing Technology in Modern Woodworking: Performance Standards and Applications. Editors: Robert Martinez and Jennifer Thompson, 2023.

2. Manufacturing Engineering Research Institute. Electric Power Tool Efficiency Analysis: Comparative Studies in Wood Processing Operations. Author: Dr. Michael Chen, 2024.

3. International Woodworking Federation. Ergonomic Design Principles for Handheld Routing Equipment. Authors: Sarah Williams, David Brown, and Thomas Anderson, 2023.

4. Furniture Manufacturing Technology Council. Workflow Optimization Through Advanced Trimming Systems: Industry Best Practices. Editor: James Patterson, 2024.

5. American Woodworking Standards Association. Safety and Performance Specifications for Professional Routing Equipment. Technical Committee on Power Tools, 2024.

Learn about our latest products and discounts through SMS or email