- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Concrete Slotting Machine Cutting Depths: What You Need to Know

Picture this scenario: You're halfway through a commercial renovation project when you realize your concrete slotting machine can't reach the depth required for electrical conduit installation. The deadline is approaching, rework costs are mounting, and your client's patience is wearing thin. Understanding cutting depth capabilities before starting your project could have prevented this costly mistake. A concrete slotting machine with the right cutting depth specifications is essential for completing professional construction projects efficiently, ensuring that electrical wiring, plumbing installations, and utility channels are properly embedded without compromising structural integrity or project timelines.

Understanding Concrete Slotting Machine Cutting Depth Specifications

When selecting a concrete slotting machine for your construction projects, cutting depth stands as one of the most critical specifications to consider. The cutting depth determines how far into the concrete surface the machine can penetrate, directly impacting the range of applications you can tackle. Modern concrete slotting machines typically offer adjustable cutting depths ranging from 15mm to 130mm, depending on the model and power rating. This adjustability provides flexibility for various installation requirements, from shallow surface channels for decorative purposes to deeper grooves needed for substantial electrical conduit or plumbing pipe installations. Professional contractors understand that cutting depth requirements vary significantly based on project specifications. For residential electrical work, depths between 20mm and 40mm often suffice for standard wiring installations. However, commercial and industrial applications frequently demand deeper cuts, sometimes exceeding 100mm, to accommodate larger conduits, multiple cable runs, or specialized utility installations. The concrete slotting machine you choose must match your typical project requirements while offering some margin for unexpected needs. The relationship between motor power and achievable cutting depth cannot be overlooked. Higher-powered machines, typically ranging from 4000W to 5500W, deliver the torque necessary to maintain consistent cutting performance at maximum depth settings. A 5500W concrete slotting machine can effortlessly handle deeper cuts through reinforced concrete, maintaining blade speed and cutting efficiency even under demanding conditions. This power advantage translates directly to productivity gains on job sites where time equals money.

Factors Affecting Maximum Cutting Depth Performance

Several variables influence the actual cutting depth performance of your concrete slotting machine beyond the manufacturer's stated specifications. Material hardness plays a substantial role—cutting through standard concrete differs significantly from penetrating granite-reinforced surfaces or aged, highly compressed concrete. The blade diameter and quality also directly affect depth capability. Larger diameter blades, such as 350mm options, naturally allow for deeper cuts compared to smaller 125mm blades commonly found on lighter-duty machines. Operating conditions significantly impact cutting depth effectiveness. Blade wear reduces effective cutting depth over time, making regular blade inspection and timely replacement essential for maintaining specified performance levels. The presence of reinforcement bars within concrete structures can limit practical cutting depth, regardless of machine specifications. Professional operators working with a concrete slotting machine must account for these real-world conditions when planning cutting operations and establishing project timelines. Water cooling systems enhance cutting depth performance by preventing blade overheating during extended deep-cutting operations. Machines equipped with integrated water pumps maintain optimal blade temperature, allowing sustained operation at maximum depth settings without performance degradation. This feature proves particularly valuable during large-scale projects requiring extensive deep grooving. The dust suppression benefit of water cooling also creates safer, cleaner working environments, an increasingly important consideration for indoor renovation projects and regulatory compliance.

Adjustable Depth Settings for Versatile Applications

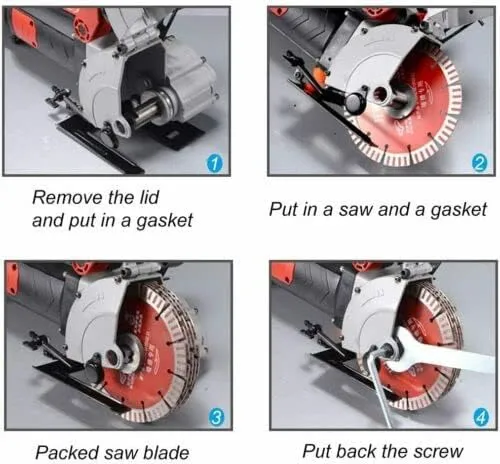

Modern concrete slotting machines feature sophisticated depth adjustment mechanisms that enable precise control over cutting depth. These adjustable systems typically employ graduated scales or digital readouts, allowing operators to set exact cutting depths required for specific applications. The ability to fine-tune depth settings transforms a single concrete slotting machine into a versatile tool capable of handling diverse project requirements, from shallow decorative grooves measuring just 15mm to substantial utility channels exceeding 100mm. The adjustment mechanism design varies across different machine models, but most professional-grade units feature front roller height adjustment systems. By raising or lowering the front support roller, operators control how deeply the blade penetrates the work surface. This intuitive adjustment method enables quick depth changes between different cutting operations, minimizing downtime during projects requiring variable groove depths. Some advanced concrete slotting machine models incorporate quick-release adjustment levers, further streamlining the depth-setting process for maximum operational efficiency. Precision matters when setting cutting depths, particularly for applications involving concealed installations. Electrical codes often specify minimum and maximum burial depths for conduits, making accurate depth control essential for code compliance. Similarly, plumbing installations require precise groove depths to ensure proper pipe positioning while maintaining adequate concrete coverage for structural integrity. A concrete slotting machine with reliable, repeatable depth adjustment capabilities helps contractors meet these exacting standards consistently across all project elements.

Optimizing Depth Settings for Different Materials

Different construction materials respond differently to slotting operations, requiring operators to adjust not only depth settings but also cutting techniques. When working with standard poured concrete, a concrete slotting machine can typically achieve maximum rated cutting depths with relative ease. However, materials like reinforced concrete, masonry blocks, or natural stone may require multiple passes at progressively deeper settings to achieve desired final groove depths without overloading the machine or damaging blades. Brick and block walls present unique challenges for depth control. The mortar joints between units create inconsistent resistance, potentially causing blade deflection or uneven cutting depths. Professional operators using a concrete slotting machine on masonry surfaces often employ slightly shallower initial passes, allowing the blade to establish a clean cutting path before increasing depth for subsequent passes. This technique produces more consistent results while extending blade life and reducing machine stress. Hard materials such as granite or marble demand conservative depth settings and patient cutting approaches. The extreme hardness of these materials generates substantial heat and wear on cutting blades, making aggressive deep cuts counterproductive. A concrete slotting machine working with natural stone typically achieves best results using moderate depth settings combined with appropriate blade selection and robust water cooling. This measured approach maintains cutting quality while preventing premature blade failure or machine damage.

Concrete Slotting Machine Power and Depth Relationship

The power rating of a concrete slotting machine directly correlates with its ability to maintain consistent cutting performance at various depths. Entry-level machines rated between 2500W and 3000W handle shallow to moderate cutting depths adequately for light residential work. However, professional contractors requiring reliable deep-cutting capability typically invest in machines rated 4000W or higher. These powerful units maintain blade speed and cutting efficiency even when operating at maximum depth settings in challenging materials. A 5500W electric wall slotting machine represents the professional standard for demanding construction applications. This power level ensures the motor can deliver consistent torque throughout extended cutting operations without overheating or performance degradation. When executing deep grooves measuring 100mm or more, the additional power reserve proves invaluable, allowing the concrete slotting machine to power through dense concrete or unexpected reinforcement without stalling or requiring reduced cutting speeds that extend project timelines. Motor quality affects performance sustainability as much as power rating. Professional-grade concrete slotting machines incorporate pure copper motor windings that offer superior electrical conductivity and heat dissipation compared to aluminum alternatives. These high-quality motors maintain performance consistency across thousands of operating hours, providing reliable service throughout the machine's operational lifespan. Investing in a concrete slotting machine with a quality motor pays dividends through reduced maintenance requirements and consistent cutting depth performance over years of professional use.

Matching Power Requirements to Project Demands

Selecting appropriate power ratings for your concrete slotting machine requires honest assessment of typical project requirements. Contractors primarily handling residential electrical and plumbing installations with maximum groove depths around 40mm can operate efficiently with mid-range power machines. However, those regularly working on commercial projects, industrial facilities, or infrastructure maintenance requiring depths exceeding 80mm should invest in high-powered units to ensure adequate performance reserves. The false economy of underpowered machines becomes apparent during demanding projects. A concrete slotting machine lacking sufficient power for required cutting depths forces operators into time-consuming multiple-pass techniques, effectively doubling or tripling cutting time compared to appropriately powered alternatives. The productivity loss often exceeds any initial purchase price savings, particularly on large-scale projects where labor efficiency directly impacts profitability. Future project flexibility represents another important consideration when evaluating power requirements. Business growth often brings opportunities for larger, more demanding projects. Purchasing a higher-powered concrete slotting machine today provides capacity to accept more challenging work tomorrow without requiring additional equipment investment. This forward-thinking approach to tool selection supports business expansion while ensuring you possess capabilities to compete for premium projects demanding superior cutting performance.

Professional Applications and Depth Requirements

Different construction applications present distinct cutting depth requirements that influence concrete slotting machine selection. Electrical installations represent one of the most common applications, with depth requirements varying based on conduit size and local electrical codes. Single-circuit residential wiring typically requires grooves between 20mm and 30mm deep, easily achieved by most concrete slotting machines. However, commercial electrical systems incorporating larger conduits or multiple cable bundles may demand grooves exceeding 50mm in depth. Plumbing installations generally require deeper cuts than electrical work due to pipe diameter requirements. Standard residential water supply lines might fit within 40mm grooves, but waste water pipes and commercial plumbing systems often necessitate channels measuring 80mm to 100mm deep. A professional concrete slotting machine with adequate cutting depth capacity handles these demanding applications efficiently, creating clean, precise grooves that accommodate piping while maintaining appropriate concrete coverage for structural integrity and code compliance. HVAC installations present some of the most challenging depth requirements, particularly when routing refrigerant lines or ventilation ducts through concrete structures. These applications may require grooves exceeding 100mm in depth, pushing concrete slotting machine capabilities to their limits. Contractors specializing in mechanical system installations typically invest in heavy-duty machines rated 5000W or higher, equipped with large-diameter blades capable of achieving maximum cutting depths in a single pass.

Specialized Construction Applications

Road construction and infrastructure maintenance projects demand exceptional cutting depth capabilities from concrete slotting machines. Creating expansion joints in highways, airport runways, or bridge decks often requires grooves measuring 100mm to 130mm deep, executed with precision to ensure proper joint function and long-term pavement performance. These demanding applications require industrial-grade concrete slotting machines designed specifically for maximum depth cutting in reinforced concrete structures. Decorative concrete work represents the opposite extreme, typically requiring shallow, precise cuts for aesthetic purposes. Pattern stamping, artistic designs, and architectural detailing seldom need cutting depths exceeding 20mm. However, precision becomes paramount in these applications, making adjustable depth control particularly valuable. A versatile concrete slotting machine capable of fine depth adjustment serves decorative concrete contractors well, enabling them to execute intricate designs with consistent, controlled cutting depths throughout each project. Industrial facility construction and renovation encompasses diverse cutting depth requirements. Installing cable trays, conduit runs, process piping, and specialized utility systems within concrete floors and walls demands flexible cutting capability across a broad depth range. Professional industrial contractors typically maintain multiple concrete slotting machines with complementary capabilities, ensuring they possess appropriate tools for whatever depth requirements specific projects present.

Conclusion

Understanding concrete slotting machine cutting depths ensures you select equipment matching your project requirements, avoiding costly delays from inadequate capability or overspending on unnecessary capacity for your typical applications.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Foshan Lifa Building Materials Co., Ltd. stands as your reliable China concrete slotting machine manufacturer, offering professional-grade equipment backed by ISO 9001 certification and comprehensive quality assurance. As a leading China concrete slotting machine supplier, we maintain extensive inventory ensuring immediate availability and fast delivery to keep your projects on schedule. Our China concrete slotting machine factory produces high-quality concrete slotting machines featuring adjustable cutting depths up to 130mm, powerful 5500W motors, and water-cooled cutting systems. Whether you need concrete slotting machines for sale for immediate deployment or seek competitive concrete slotting machine prices with OEM customization support, our experienced team delivers expert guidance throughout the procurement process. Partner with a trusted China concrete slotting machine wholesale provider serving over 30 countries worldwide. Contact us today at wz@jiancaiqy.com for detailed specifications, pricing, and how our high-quality concrete slotting machines can enhance your construction capabilities.

References

1. Smith, J. and Anderson, M. "Concrete Cutting Technologies: Principles and Applications." Construction Equipment Journal, 2023.

2. Williams, R. "Depth Control Mechanisms in Modern Wall Slotting Equipment." Building Technology Review, 2024.

3. Thompson, K. et al. "Power Requirements for Deep Concrete Grooving Operations." International Construction Equipment Studies, 2023.

4. Davis, L. "Material-Specific Cutting Techniques for Professional Contractors." Professional Builder's Guide, 2024.

5. Martinez, C. and Lee, S. "Safety and Efficiency in Concrete Slotting Operations." Construction Safety Institute, 2023.

Learn about our latest products and discounts through SMS or email