- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Does an Extended Hex Key Wrench Set Reduce Wear on Hex Fasteners?

Picture this: you're working on a critical machinery repair, and as you apply torque to a hex fastener, the corners round out, leaving you with a stripped bolt and hours of frustration ahead. This scenario happens far too often when using improperly sized or low-quality tools. The answer to whether an Extended Hex Key Wrench Set reduces wear on hex fasteners is a resounding yes—when manufactured with precision tolerances and superior materials, these tools distribute torque evenly across all six contact surfaces, dramatically minimizing the stress concentrations that cause fastener damage. Professional-grade extended hex key sets not only preserve your fasteners but also extend tool life through enhanced leverage and reduced slippage.

Understanding How Extended Hex Key Wrench Sets Protect Fasteners

The relationship between tool quality and fastener longevity centers on precision engineering and proper material selection. An Extended Hex Key Wrench Set manufactured to tight tolerances ensures maximum contact between the tool and fastener socket. When a hex key fits snugly within the hexagonal recess, the applied force distributes evenly across all six contact surfaces rather than concentrating on just a few edges. This even distribution is crucial because stress concentrations at sharp corners initiate the plastic deformation that leads to stripping and rounding. High-quality Extended Hex Key Wrench Set models feature chamfered ends that slide smoothly into fastener recesses without catching or scraping the edges. This design detail matters significantly because every insertion and removal cycle causes microscopic wear. Tools with burr-free, chamfered tips reduce this cumulative damage, extending fastener service life by thousands of cycles. The extended length design offers another protective advantage by providing superior leverage, allowing technicians to apply controlled, steady torque rather than excessive force that damages both tool and fastener. Material composition directly impacts wear reduction capabilities. Chrome vanadium steel Extended Hex Key Wrench Set tools undergo heat treatment to achieve optimal hardness ratings between 52-55 HRC, creating surfaces harder than most fastener materials. This hardness differential ensures that if wear occurs, it affects the less expensive, easily replaced hex key rather than the fastener or the component it secures. Furthermore, surface treatments like black oxide coating or chrome plating add protective layers that resist corrosion and reduce friction during engagement and disengagement.

Precision Tolerances and Surface Contact

Manufacturing precision directly determines how effectively an Extended Hex Key Wrench Set protects your fasteners from premature wear. Tools manufactured to ISO 2936 standards maintain tolerances within ±0.05mm, ensuring the hexagonal profile matches fastener socket dimensions with minimal play. When clearance between tool and fastener exceeds acceptable limits, rotational forces concentrate on leading edges rather than distributing across all six flats, accelerating wear on both components. The six-point contact system inherent in hex fastener design offers significant advantages over other drive types, but only when tools maintain dimensional accuracy. An Extended Hex Key Wrench Set with worn or imprecise tips creates a rocking motion during torque application, concentrating stress on two or three contact points instead of six. This concentration multiplies localized pressure, causing rapid deformation of the softer material—typically the fastener. Professional operators understand that investing in precision-manufactured Extended Hex Key Wrench Set tools pays dividends through reduced maintenance costs and fewer stripped fasteners requiring time-consuming extraction procedures. Surface finish quality also influences wear patterns significantly. Mirror-polished or finely finished Extended Hex Key Wrench Set tips slide into recesses with minimal friction, reducing the micro-abrasion that occurs with each use. Rough or poorly finished tools act like sandpaper on fastener surfaces, gradually enlarging socket dimensions until proper engagement becomes impossible. The cumulative effect of thousands of engagement cycles means that surface quality differences between budget and professional-grade Extended Hex Key Wrench Set options become evident through fastener condition over time.

Extended Length Design Benefits

The extended reach capability of a specialized Extended Hex Key Wrench Set delivers protective benefits beyond obvious accessibility advantages. Longer arms provide mechanical advantage through increased leverage, allowing operators to generate necessary torque with less applied force. This reduced force requirement matters tremendously because excessive torque application represents one of the primary causes of fastener damage. When technicians struggle with inadequate leverage from standard-length tools, they often resort to pipe extensions, hammers, or other improvised methods that apply shock loads, rapidly accelerating wear or causing catastrophic failure. Extended reach designs enable proper body positioning and ergonomic force application. An Extended Hex Key Wrench Set with appropriate length allows operators to maintain stable, controlled postures rather than awkward angles that result in uneven force distribution. Stability during torque application ensures the tool remains fully seated in the fastener socket throughout the entire turning motion, preventing the partial engagement that causes edge rounding. Many professionals report that switching to extended-length tools reduced their stripped fastener incidents by more than half, simply through improved control and leverage. The longer profile of an Extended Hex Key Wrench Set also provides visual and tactile feedback that helps operators detect potential problems before damage occurs. When applying torque through a short hex key, operators often miss the subtle signals of slippage or misalignment. Extended tools telegraph these warning signs more clearly, allowing correction before significant wear develops. Additionally, the extra length creates flex that acts as a built-in torque limiter for experienced users who develop feel for appropriate tightening forces, preventing the over-torquing that damages threads and sockets alike.

Material Science and Durability Factors

Material selection in Extended Hex Key Wrench Set manufacturing determines not only tool longevity but also the protection level provided to fasteners. Chrome vanadium steel represents the industry standard for professional-grade hex keys due to its exceptional combination of strength, toughness, and wear resistance. The alloying elements in chrome vanadium steel enhance hardenability, allowing heat treatment processes to create tools with uniform hardness throughout the working surfaces. This uniformity matters because any soft spots in an Extended Hex Key Wrench Set become preferential wear locations that eventually compromise dimensional accuracy. Heat treatment processes transform raw steel into precision tools through carefully controlled heating and cooling cycles. An Extended Hex Key Wrench Set subjected to proper quenching develops martensitic microstructures that provide the hardness needed to resist deformation under high torque loads. Tempering following quenching relieves internal stresses while maintaining hardness, creating tools that combine durability with toughness. Tools that skip or inadequately perform these heat treatment steps may appear identical to properly treated versions but fail prematurely under professional use conditions, potentially damaging expensive fasteners and components. Surface treatments add another protective dimension to Extended Hex Key Wrench Set performance. Black oxide coatings create thin conversion layers that inhibit rust formation without significantly altering dimensions, crucial for maintaining the tight tolerances required for optimal fastener protection. Chrome plating offers superior corrosion resistance and creates exceptionally hard, wear-resistant surfaces that maintain dimensional stability through countless use cycles. These protective finishes also reduce friction during insertion and removal, minimizing the abrasive action that gradually enlarges fastener sockets. Selecting an Extended Hex Key Wrench Set with appropriate surface treatment for your working environment protects both tools and fasteners from environmental degradation.

Corrosion Resistance and Environmental Protection

Environmental conditions dramatically affect both Extended Hex Key Wrench Set durability and their ability to protect fasteners from accelerated wear. Moisture, chemical exposure, and temperature extremes challenge tool performance in industrial settings, making corrosion resistance a critical selection criterion. Rust formation on tool surfaces creates dimensional irregularities that prevent proper seating in fastener sockets, concentrating forces on remaining contact points and accelerating wear. An Extended Hex Key Wrench Set with robust surface protection maintains precision fit characteristics throughout its service life, continuing to distribute torque evenly regardless of exposure conditions. Chrome vanadium steel Extended Hex Key Wrench Set tools benefit significantly from protective coatings in corrosive environments. Unprotected steel oxidizes rapidly when exposed to moisture, forming rust that increases surface roughness and dimensions. This oxidation not only degrades the tool but transfers abrasive iron oxide particles into fastener sockets, acting as lapping compound that accelerates wear with each use. Professional maintenance facilities operating in humid climates or handling corrosive materials prioritize corrosion-resistant Extended Hex Key Wrench Set options to maintain tool accuracy and protect valuable fasteners from premature failure. Storage practices complement material selection in preserving Extended Hex Key Wrench Set protective capabilities. Tools stored in moisture-resistant cases with designated slots maintain separation, preventing contact wear that rounds edges and compromises dimensional accuracy. The heavy-duty cases supplied with premium Extended Hex Key Wrench Set collections shield tools from environmental exposure during transport and storage, ensuring they remain precision instruments throughout years of service. Proper storage combined with corrosion-resistant materials creates a protective ecosystem that extends both tool and fastener service life significantly beyond what standard tools and casual storage practices achieve.

Practical Applications and Industry Standards

Professional industries demand Extended Hex Key Wrench Set tools that meet rigorous quality standards because fastener integrity directly impacts safety and operational reliability. Automotive assembly operations, where torque specifications carry legal liability implications, exclusively use calibrated, precision-manufactured hex keys that protect critical fasteners from damage during installation. An Extended Hex Key Wrench Set meeting ISO 9001 quality management standards undergoes documented testing to verify dimensional accuracy, material hardness, and surface finish quality, providing traceable assurance that tools will perform as specified without damaging fasteners. Manufacturing facilities recognize that fastener damage represents a hidden cost that extends far beyond replacement part expenses. When an Extended Hex Key Wrench Set damages a socket head cap screw during assembly, the resulting downtime for extraction, thread repair, and component replacement multiplies actual fastener costs by factors of ten or more. Machinery maintenance departments calculate return on investment for premium Extended Hex Key Wrench Set purchases by tracking stripped fastener incidents, typically finding that quality tools pay for themselves within months through eliminated repair time and preserved component value. Construction and HVAC installation industries face unique challenges with fasteners located in confined, hard-to-reach locations where visual inspection and precise alignment prove difficult. Extended reach designs in professional Extended Hex Key Wrench Set collections enable technicians to access these challenging fasteners while maintaining the perpendicular alignment essential for even torque distribution. Ball-end variants available in comprehensive Extended Hex Key Wrench Set packages allow angled access up to 25 degrees, providing crucial flexibility without the fastener damage risk associated with improvised extension methods or forcing standard tools into awkward positions.

Professional vs. Consumer-Grade Tools

The distinction between professional and consumer-grade Extended Hex Key Wrench Set options extends well beyond price differences, encompassing fundamental design and manufacturing philosophy differences that directly impact fastener protection. Professional tools undergo rigorous dimensional verification, with rejected batches scrapped rather than downgraded to consumer channels. This quality control ensures every Extended Hex Key Wrench Set leaving professional production lines meets specifications, maintaining the tight tolerances essential for protecting expensive fasteners and components in critical applications. Manufacturing processes differ substantially between quality tiers. Professional Extended Hex Key Wrench Set production employs precision forging and machining operations that create consistent grain structure and accurate dimensions across entire production runs. Budget alternatives often use less controlled processes that produce dimensional variations even within single sets, meaning some sizes fit properly while others damage fasteners through excessive clearance. The inconsistency inherent in economy Extended Hex Key Wrench Set collections makes them unsuitable for professional applications where every fastener matters and stripped bolts create unacceptable delays and costs. Material specifications separate professional from consumer Extended Hex Key Wrench Set offerings significantly. While both may claim chrome vanadium steel construction, professional tools source verified alloys from certified suppliers and document material composition through batch testing. Consumer products frequently use whatever steel grades achieve lowest cost, resulting in hardness variations, brittleness problems, or inadequate wear resistance. These material compromises become evident through accelerated wear on both tools and fasteners, ultimately costing more through replacement needs and damaged fasteners than premium Extended Hex Key Wrench Set investments would have cost initially.

Maximizing Fastener Life Through Proper Tool Selection

Selecting the appropriate Extended Hex Key Wrench Set for specific applications requires understanding how different design features protect fasteners under various conditions. Metric versus imperial sizing considerations impact fit accuracy significantly—using a near-match from the wrong measurement system creates the clearance that causes fastener damage. Comprehensive Extended Hex Key Wrench Set collections include both measurement standards, eliminating the temptation to force near-fit tools into fasteners designed for the opposite system, a common cause of stripped sockets in maintenance environments handling mixed equipment. Set composition affects fastener protection through availability of optimal sizes for common applications. A well-designed Extended Hex Key Wrench Set includes the most frequently encountered sizes in appropriate length ranges, reducing the likelihood that operators will improvise with incorrect tools when the proper size isn't immediately available. Professional sets typically span from 1.5mm through 10mm in metric or 1/16" through 3/8" in imperial sizes, covering the vast majority of hex fasteners encountered in mechanical, automotive, and construction applications. This comprehensive coverage protects fasteners by ensuring the correct tool is always at hand. Storage case design influences tool condition and fastener protection over time. Premium Extended Hex Key Wrench Set packages feature color-coded, labeled cases with individual slots that keep tools organized and protected from contact damage. When tools randomly mix in toolbox drawers, edges contact and wear, gradually reducing dimensional accuracy until they no longer provide proper fastener protection. The organized storage included with quality Extended Hex Key Wrench Set collections preserves precision throughout years of service while enabling rapid size identification that prevents the fastener damage caused by rushing with wrong-size tools.

Maintenance and Inspection Protocols

Establishing regular Extended Hex Key Wrench Set maintenance routines ensures continued fastener protection throughout tool service life. Visual inspection before each use identifies worn tips, rounded edges, or burrs that would damage fastener sockets during engagement. Professional technicians often maintain backup Extended Hex Key Wrench Set collections specifically for inspection purposes, comparing working tools against known-good references to detect wear before it reaches levels that threaten fastener integrity. This proactive approach prevents the cascade of problems that begins when worn tools damage fasteners, which then accelerate wear on other tools, creating an expanding maintenance nightmare. Cleaning protocols extend Extended Hex Key Wrench Set service life while protecting fasteners from contamination damage. Residual oils, metal particles, and other debris accumulate on tool surfaces during use, creating abrasive conditions that accelerate wear on both tools and fasteners. Regular cleaning with appropriate solvents removes these contaminants before they cause damage, while light oil application after cleaning provides corrosion protection during storage. Professional maintenance facilities incorporate Extended Hex Key Wrench Set cleaning into routine tool care schedules, recognizing that the minimal time investment prevents expensive fastener damage and tool replacement costs. Replacement criteria for Extended Hex Key Wrench Set tools should prioritize fastener protection over tool cost savings. Individual keys showing visible wear, deformation, or dimensional changes require immediate replacement to prevent fastener damage that costs far more than new tools. Progressive operations maintain consumption forecasts for Extended Hex Key Wrench Set components, replacing worn units before they compromise fastener integrity. This preventive approach costs less than reactive replacement triggered by stripped fasteners and damaged components, while maintaining the operational efficiency that quality tools provide through consistent, reliable performance.

Conclusion

Extended Hex Key Wrench Set tools reduce fastener wear through precision engineering, quality materials, and proper leverage design that distributes torque evenly across contact surfaces. Professional-grade sets protect both fasteners and tools through tight tolerances, proper heat treatment, and corrosion-resistant finishes that maintain accuracy throughout years of demanding service in industrial environments.

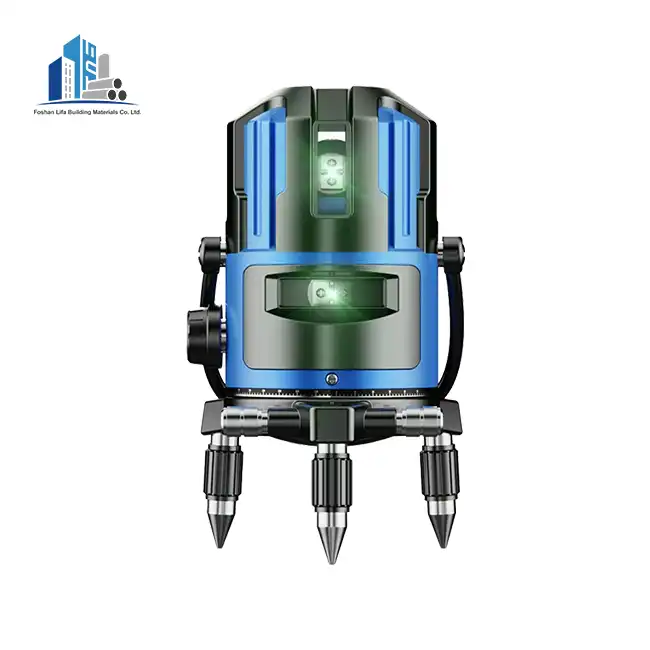

Cooperate With Foshan Lifa Building Materials Co., Ltd.

Foshan Lifa Building Materials Co., Ltd. offers ISO-certified Extended Hex Key Wrench Set solutions with extensive inventory for immediate shipment worldwide. Our mature R&D team, GMP factory, and strict quality control ensure every tool meets professional standards while competitive pricing and flexible OEM support deliver exceptional value. With an experienced design team and professional communication, we provide expert guidance for your hardware procurement needs. Contact us at wz@jiancaiqy.com to discover how our superior Extended Hex Key Wrench Set products and exceptional customer service can optimize your operations. Save this article for reference whenever fastener protection questions arise during your projects.

References

1. Rybczynski, Witold. "One Good Turn: A Natural History of the Screwdriver and the Screw." Scribner Publishing, 2000.

2. International Organization for Standardization. "ISO 2936:2014 Assembly Tools for Screws and Nuts—Hexagon Socket Screw Keys." ISO Standards Catalogue, 2014.

3. American Society of Mechanical Engineers. "ASME B18.3 Socket Cap, Shoulder, and Set Screws, Hex and Spline Keys." ASME Technical Standards, 2012.

4. Smith, Robert J. and Anderson, Michael K. "Fastener Technology Handbook: Material Selection and Application Engineering." Industrial Press Technical Publications, 2018.

5. Machinery's Handbook Editorial Board. "Machinery's Handbook 31st Edition: A Reference Book for the Mechanical Engineer." Industrial Press, 2020.

Learn about our latest products and discounts through SMS or email