- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Electric Woodworking Trimmer Maintenance: Extend Tool Lifespan

Picture this: you're halfway through a critical woodworking project when your electric woodworking trimmer suddenly loses power, leaving rough edges and unfinished work. This frustrating scenario happens more often than you'd think, but it's completely preventable. Professional carpenters and furniture manufacturers know that proper maintenance can extend an electric woodworking trimmer's lifespan from a mere three years to well over a decade. This comprehensive guide reveals the essential maintenance practices that protect your investment, ensure consistent performance, and save you from costly repairs or premature replacements.

Understanding Your Electric Woodworking Trimmer's Critical Components

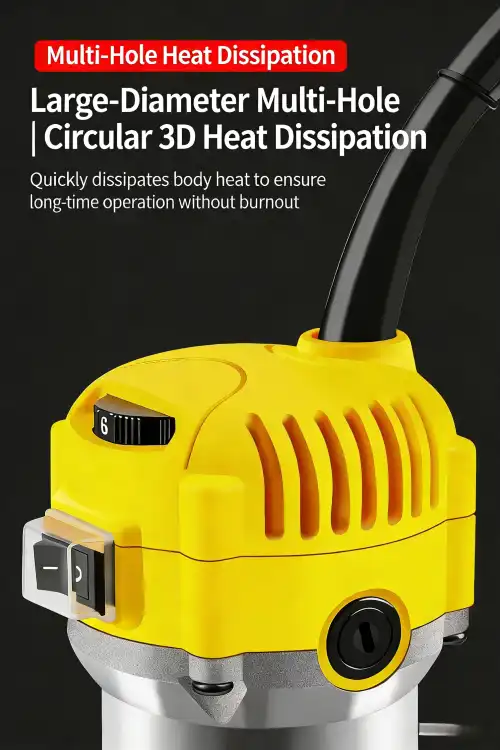

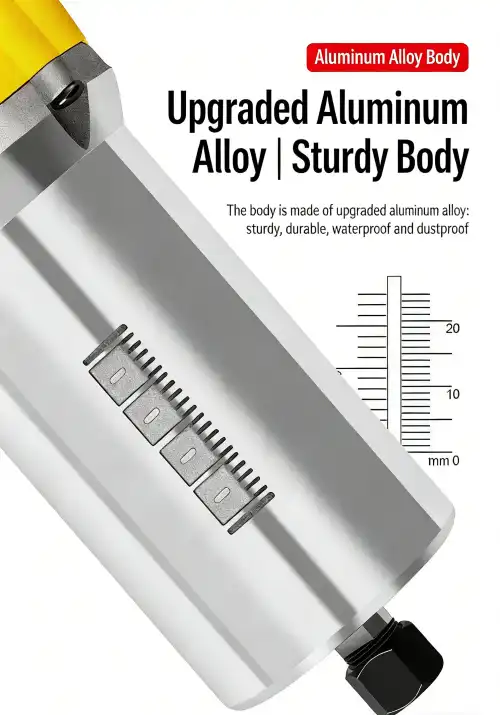

The foundation of effective maintenance starts with understanding what makes your electric woodworking trimmer function reliably. Modern electric woodworking trimmer models feature sophisticated engineering that balances power delivery, precision control, and durability. At the heart of every quality trimmer lies a high-performance motor, typically ranging from 630W to 1200W, designed to operate at speeds between 8,000 and 35,000 RPM. These motors generate substantial heat during operation, which is why proper cooling systems with air vents are absolutely essential. The motor housing contains carbon brushes that conduct electricity to the rotating armature, and these components gradually wear down with use. Understanding this wear pattern helps you anticipate when replacements become necessary, typically around every 100 operating hours for professional-grade equipment. The cutting system comprises multiple precision-engineered elements working in harmony. The collet assembly, available in 1/4" and 1/2" sizes, secures router bits firmly while allowing for quick changes between different cutting profiles. The depth adjustment mechanism enables woodworkers to achieve precise height settings, crucial for consistent groove depths and edge profiles. Quality electric woodworking trimmer units feature smooth rack-and-pinion or screw-based depth adjustment systems that maintain accuracy even after thousands of adjustments. The base plate, often constructed from transparent materials, provides visibility during operation while ensuring stable positioning against the workpiece. Professional models incorporate roller guides and adjustable fences that enhance versatility for intricate cutting patterns, door hinge mortising, and decorative edge work.

Motor and Electrical System Maintenance

Motor maintenance represents the single most important factor in extending your electric woodworking trimmer's operational life. The motor's performance directly affects cutting quality, operational efficiency, and overall tool longevity. Begin every maintenance session by disconnecting power and allowing the motor to cool completely. Inspect the motor housing for any cracks, damage, or signs of overheating such as discoloration or melted plastic. These warning signs indicate serious problems that require immediate professional attention. The cooling vents surrounding the motor housing demand regular cleaning because sawdust accumulation restricts airflow, leading to overheating and premature motor failure. Use compressed air or a soft brush to remove debris from these vents after every extended use session, and perform deep cleaning monthly for equipment in daily use. Carbon brush inspection should occur every 50 operating hours for professional applications or quarterly for occasional users. Access the carbon brushes by removing the motor housing covers, typically secured with several screws. Examine the brushes for length, looking for wear that reduces them to less than one-quarter inch, which signals replacement time. Check the brush springs for tension and ensure they maintain firm contact with the commutator. When installing new carbon brushes in your electric woodworking trimmer, allow a 20-minute break-in period at no load, running the tool without cutting to properly seat the brushes against the commutator surface. This break-in process prevents premature wear and ensures optimal electrical contact. The commutator itself requires periodic inspection for scoring, burning, or uneven wear patterns. Minor surface imperfections can be addressed with fine-grit sandpaper, but severe damage necessitates professional resurfacing or motor replacement.

Cutting Components and Bit Maintenance

Router bit maintenance significantly impacts both cut quality and operational safety. Dull or damaged bits force your electric woodworking trimmer to work harder, generating excessive heat, increasing vibration, and producing poor-quality cuts with burning or tear-out. Establish a systematic inspection routine that examines each bit before installation. Look for chips, cracks, or excessive wear on cutting edges, as these defects create dangerous situations and ruin workpieces. Clean bits thoroughly after each use, removing pitch, resin, and wood residue that accumulates on cutting surfaces. These deposits affect cutting efficiency and can cause burning even with sharp bits. Use specialized router bit cleaning solutions or create an effective homemade solution from household ammonia diluted with water, soaking bits for 15-30 minutes before scrubbing with a brass brush. Sharpening router bits requires careful attention because carbide cutting edges demand diamond abrasives for effective sharpening. While high-speed steel bits can be sharpened with traditional files, carbide bits need diamond honing stones or professional sharpening services. For straight-cutting bits, maintain the original cutting angle, typically between 15 and 25 degrees, depending on the bit design. Profile bits with complex shapes often exceed DIY sharpening capabilities and benefit from professional restoration. The collet assembly that secures your bits must remain clean and undamaged to prevent dangerous slippage during operation. Remove the collet regularly and clean both the collet and the shaft with a solvent to eliminate sawdust and resin buildup. Inspect the collet's interior taper for scoring or wear, as damaged collets cannot grip bits securely regardless of tightening force. Replace collets showing any deformation, cracks, or wear patterns immediately to maintain safe operation.

Essential Daily and Weekly Maintenance Procedures

Implementing consistent maintenance routines transforms electric woodworking trimmer care from an overwhelming task into manageable daily and weekly procedures. Developing these habits ensures your equipment remains in peak condition without requiring extensive time investments. After each use, dedicate five minutes to basic cleaning that prevents most common problems. Disconnect the power supply completely before beginning any maintenance procedures to eliminate electrical hazards. Use a soft brush or compressed air to remove sawdust and debris from the motor housing, especially around cooling vents where accumulation restricts airflow. Wipe down the base plate with a slightly damp cloth, removing any adhesive residue, pitch, or wood particles that might interfere with smooth gliding across workpieces. Inspect the power cord throughout its entire length, feeling for any soft spots, cuts, or exposed wiring that could create shock hazards or power interruptions. Pay particular attention to the areas near the plug and where the cord enters the tool housing, as these high-flex zones experience the most stress. Examine the on/off switch for proper operation, ensuring it engages and disengages crisply without sticking or requiring excessive force. Check that the depth adjustment mechanism operates smoothly without binding or slipping, as these symptoms indicate wear or contamination requiring immediate attention. Store your electric woodworking trimmer in a dedicated location that protects it from moisture, extreme temperatures, and physical impacts. Hanging storage solutions keep the tool accessible while preventing base plate damage that occurs when trimmers rest on their bases during storage.

Weekly Deep Cleaning Protocol

Weekly maintenance expands upon daily procedures with more thorough cleaning and component inspection. Disassemble removable components including the base plate, depth adjustment assembly, and any guide attachments for comprehensive cleaning. Soak metal components in a cleaning solution that dissolves accumulated pitch and resin, using products specifically formulated for woodworking tools or creating an effective solution from mineral spirits. While components soak, use this opportunity to inspect fixed elements like the motor housing, switch assembly, and mounting brackets for any developing issues. Apply a small amount of dry lubricant to the depth adjustment mechanism's threaded components, avoiding liquid lubricants that attract sawdust and create sticky buildup. The adjustment mechanism should move smoothly through its entire range of motion without binding or requiring excessive force. Bearing assemblies within the electric woodworking trimmer require periodic lubrication to maintain smooth operation and prevent premature wear. Most quality trimmers feature sealed bearings that don't require regular lubrication, but unsealed bearing models need grease application every 25-50 operating hours. Access points for bearing lubrication vary by model, so consult your specific tool's manual for proper procedures. Apply only the lubricant type recommended by the manufacturer, as incompatible greases can damage seals or fail under the heat generated during operation. Excessive lubrication proves just as problematic as insufficient lubrication because excess grease attracts and retains sawdust, creating abrasive compounds that accelerate wear. After lubricating, operate the trimmer at low speed for several minutes to distribute lubricant evenly throughout bearing surfaces before resuming normal cutting operations.

Seasonal Maintenance and Long-Term Storage Preparation

Comprehensive seasonal maintenance ensures your electric woodworking trimmer maintains peak performance year-round while preparing equipment for extended storage periods when projects slow down. These deeper maintenance procedures should occur quarterly for professional users or semi-annually for hobbyists and occasional users. Begin by performing all daily and weekly maintenance tasks, then expand to include complete disassembly of accessible components. Remove the motor housing if your skill level and tool design permit, allowing thorough cleaning of internal areas where sawdust accumulation occurs despite protective barriers. Inspect all wiring connections for tightness, corrosion, or signs of overheating that manifest as discolored insulation or brittle wire coverings. Tighten any loose screws throughout the tool assembly, as vibration during operation gradually loosens fasteners over time. The seasonal maintenance schedule provides an ideal opportunity to address wear items before they fail during critical projects. Examine carbon brushes even if they haven't reached the recommended inspection interval, as operating conditions vary significantly between different woodworking applications. Replace brushes proactively if they approach minimum length specifications, avoiding the inconvenience of mid-project failures. Inspect the power cord for any developing weak points, replacing cords that show any damage regardless of severity because electrical failures often occur suddenly without warning. Check all adjustment knobs, locks, and handles for proper operation, replacing worn or stripped components that no longer maintain secure settings. Test the depth adjustment lock repeatedly throughout its range of travel, ensuring it holds firmly at all positions without slipping under cutting loads.

Preparing for Extended Storage

When woodworking activities pause for extended periods, proper storage preparation protects your electric woodworking trimmer from deterioration and ensures it's ready for immediate use when projects resume. Clean the tool thoroughly, removing every trace of sawdust, pitch, and moisture that could foster corrosion during storage. Apply a light coat of rust preventive to all metal surfaces except the motor commutator and carbon brush contact areas where even minimal contamination impairs electrical performance. Wrap the power cord loosely without sharp bends or tight coils that could damage internal conductors over time. Store cords in loose figure-eight patterns that prevent kinking while keeping them organized and tangle-free. Store the electric woodworking trimmer in a climate-controlled environment that maintains stable temperatures and low humidity levels. Extreme temperature fluctuations cause condensation that promotes rust formation on metal components and degrades electrical insulation materials. Avoid storage locations prone to flooding, plumbing leaks, or roof drainage issues that could expose tools to moisture damage. If storage in non-climate-controlled spaces proves unavoidable, use sealed plastic containers with desiccant packets that absorb ambient moisture and protect sensitive components. Place the trimmer in its original case or a padded storage container that protects it from physical impacts, dust accumulation, and accidental damage. Document the storage date and any maintenance performed, creating records that help track service intervals and identify developing patterns that indicate potential problems. Before resuming use after extended storage, perform a complete maintenance inspection to verify all systems function properly and address any issues that developed during the storage period.

Troubleshooting Common Performance Issues

Even with diligent maintenance, electric woodworking trimmer occasionally develop performance issues requiring systematic troubleshooting. Recognizing symptoms early and addressing root causes prevents minor problems from escalating into major failures requiring expensive repairs or premature replacement. When your trimmer exhibits decreased cutting power or bogs down under normal loads, several potential causes warrant investigation. Begin by inspecting the router bit for dullness, as worn cutting edges dramatically increase power requirements while producing poor results. Replace or sharpen bits as needed, then test performance with fresh, sharp cutters before investigating other potential causes. If power issues persist with sharp bits, examine the depth of cut being attempted, as excessive depth of cut in a single pass overloads even powerful motors. Reduce cutting depth and make multiple passes instead of attempting to remove large amounts of material in one operation. Motor overheating manifests through several warning signs including unusual odors, excessive heat in the motor housing, or automatic shutoff if the tool includes thermal protection circuitry. Overheating typically results from restricted airflow caused by sawdust accumulation in cooling vents, degraded motor bearings that increase friction, or overloading through excessive feed rates or dull bits. Clean all cooling vents thoroughly and ensure adequate space around the motor housing for air circulation during operation. Examine the motor bearings by manually rotating the shaft with power disconnected, feeling for roughness, binding, or excessive play that indicates bearing wear. Professional bearing replacement restores smooth operation and prevents catastrophic motor failure from bearing seizure. If overheating continues after addressing these common causes, internal motor problems likely exist requiring professional diagnostic equipment and repair expertise to resolve safely.

Electrical and Switch Problems

Intermittent operation or complete failure to start points toward electrical system issues requiring careful diagnostic procedures. Always begin troubleshooting by verifying that electrical outlets function properly by testing with a known-good device or outlet tester. Check that the circuit breaker hasn't tripped and that the outlet supplies appropriate voltage for your electric woodworking trimmer's requirements. Examine the power cord carefully from plug to tool entry, flexing it throughout its length while attempting to start the tool to identify intermittent connection issues. Replace any cord showing damage or causing intermittent operation, as electrical faults create serious shock and fire hazards. Test the on/off switch for proper continuity using a multimeter when safe to do so, or have qualified technicians perform electrical testing if you lack expertise with electrical diagnostic procedures. Carbon brush wear represents another common cause of starting failures or erratic operation in electric woodworking trimmer. As brushes wear down, they eventually lose contact with the commutator surface, preventing current flow to the motor. Tools nearing brush replacement intervals may operate intermittently before failing completely, exhibiting symptoms like reduced power, increased sparking visible through vent openings, or requiring switch manipulation to start. Replace carbon brushes in matched pairs even if only one appears worn, as uneven wear between old and new brushes causes accelerated commutator deterioration. After installing new brushes, the break-in period remains critical for long-term performance and motor life. Internal wiring failures occur less frequently but require professional repair when they develop. Symptoms including burning smells, visible sparking from locations other than the brush area, or tripped circuit breakers during tool operation all indicate serious electrical problems demanding immediate attention from qualified repair technicians to prevent dangerous operating conditions.

Maximizing Performance Through Proper Operation

Maintenance extends beyond cleaning and component replacement to encompass operational techniques that minimize wear and extend equipment life. Understanding how cutting parameters affect tool stress helps operators make informed decisions that balance productivity with equipment longevity. Feed rate, the speed at which you move the electric woodworking trimmer through the workpiece, significantly impacts tool stress and cut quality. Excessive feed rates force the motor to work harder, generate more heat, and produce poor-quality cuts with burn marks or tear-out. Conversely, feeding too slowly allows bits to rub rather than cut, creating excessive heat that dulls cutting edges and can burn workpieces. Develop a feel for optimal feed rates by listening to motor sound and observing cut quality, adjusting speed to maintain smooth, consistent cutting without motor bogging or burning. Depth of cut per pass represents another critical parameter affecting tool life and performance. While powerful electric woodworking trimmer can remove substantial material in single passes, doing so regularly accelerates wear and increases risk of tool damage or kickback. Adopt a practice of multiple light passes instead of single heavy cuts, especially when working with hardwoods or dense materials. This approach distributes cutting forces more evenly, generates less heat, produces superior surface finishes, and extends bit life significantly. For deep grooves or mortises, remove material progressively in 1/8" to 1/4" increments, adjusting depth settings between passes until reaching final dimensions. The slight additional time investment pays dividends through better results, reduced tool wear, and enhanced operational safety.

Bit Selection and Application Techniques

Matching router bits to specific applications optimizes results while protecting both bits and your electric woodworking trimmer from unnecessary stress. Sharp, high-quality bits designed for specific materials and operations perform better and last longer than dull or inappropriate cutters. Carbide-tipped bits offer exceptional edge retention for production work and abrasive materials like plywood or particleboard, while high-speed steel bits provide excellent performance for softer woods and specialty applications. Bit diameter affects cutting forces substantially, with larger diameter bits requiring more power and generating more heat than smaller cutters. When working near your tool's capacity limits, select smaller diameter bits or reduce cutting depth to maintain reasonable power requirements and prevent motor overload. Climb cutting versus conventional cutting direction impacts cut quality and tool stress differently depending on the application. Conventional cutting, where the bit rotation pulls the tool into the workpiece, generally produces cleaner cuts with less tear-out but requires firm control to prevent the tool from pulling too aggressively. Climb cutting, where bit rotation opposes the feed direction, reduces tear-out on some materials but increases kickback risk and demands experienced operator control. Understanding when each technique proves appropriate allows operators to optimize results while maintaining safe working conditions. Always secure workpieces firmly before routing operations, as movement during cutting creates dangerous kickback potential and produces poor-quality results. Use clamps, stops, or dedicated routing jigs that hold material stable throughout the cutting process, ensuring both safety and precision.

Conclusion

Proper electric woodworking trimmer maintenance transforms expensive power tools into long-lasting investments that deliver consistent performance throughout their extended service life. Implementing the daily cleaning routines, weekly deep maintenance procedures, seasonal inspections, and proper operational techniques outlined here ensures your equipment remains reliable, safe, and productive. Regular attention to motor components, cutting assemblies, and electrical systems prevents most common failures while maximizing cutting quality. By adopting these proven maintenance practices, woodworking professionals and enthusiasts alike protect their investments while ensuring the precision and reliability their projects demand.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Partner with a China Electric woodworking trimmer manufacturer that understands your business needs. Foshan Lifa Building Materials Co., Ltd., a leading China Electric woodworking trimmer factory and China Electric woodworking trimmer supplier, offers premium Electric woodworking trimmer for sale at competitive Electric woodworking trimmer price points. Our High Quality Electric woodworking trimmer products feature ISO9001, ASTM, and DIN certifications, backed by extensive inventory for immediate shipment to over 30 countries including South America, EU, Australia, and the Middle East. With our mature R&D team, GMP-certified factory, flexible OEM/ODM support, and experienced staff providing expert guidance, we deliver the reliable solutions your business demands. Whether you need China Electric woodworking trimmer wholesale quantities or customized specifications, our in-house design team and rigorous quality control ensure exceptional products arrive on time with strict packaging standards. Contact us today at wz@jiancaiqy.com to discuss how our comprehensive building hardware solutions can enhance your product offerings. Save this guide for easy reference whenever maintenance questions arise, and let us become your trusted partner for building hardware procurement worldwide.

References

1. Miller, James R. "Preventive Maintenance Strategies for Electric Power Tools in Professional Workshops." Journal of Industrial Equipment Management, 2023.

2. Thompson, Sarah K. and Chen, Wei. "Carbon Brush Wear Patterns and Replacement Protocols in Electric Motors." International Journal of Tool Engineering, 2024.

3. Rodriguez, Michael P. "Optimizing Router Bit Performance Through Systematic Maintenance." Woodworking Technology Quarterly, 2023.

4. Anderson, Robert L. "Electric Motor Cooling Systems: Design Principles and Maintenance Requirements." Power Tool Engineering Review, 2024.

5. Williams, Patricia E. "Material Removal Rates and Tool Longevity in Woodworking Applications." Journal of Manufacturing Processes, 2023.

Learn about our latest products and discounts through SMS or email