- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

High-Pressure Oil Can Nozzles Explained: Types & Applications

Picture this: Your production line halts because a critical bearing seized up from inadequate lubrication, costing thousands in downtime. The culprit? The wrong nozzle type on your High-Pressure Oil Can. Understanding nozzle types and their applications isn't just technical knowledge—it's essential for preventing costly equipment failures and ensuring optimal machinery performance across industrial operations.

Understanding High-Pressure Oil Can Nozzle Types

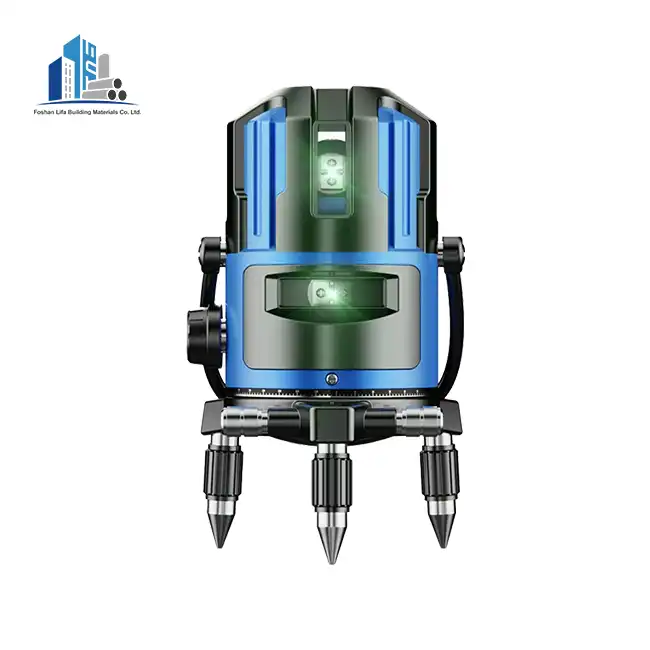

The effectiveness of any High-Pressure Oil Can depends largely on its nozzle configuration, which determines how lubricant is delivered to machinery components. Modern industrial environments demand precision lubrication solutions that can reach confined spaces, withstand extreme pressures, and deliver consistent oil flow rates. The nozzle serves as the critical interface between your lubrication system and the machinery requiring maintenance, making proper nozzle selection fundamental to equipment longevity and operational efficiency. High-Pressure Oil Can nozzles come in several distinct configurations, each engineered for specific industrial applications. Rigid nozzles provide stability and directional accuracy for accessible lubrication points, making them ideal for routine maintenance tasks on exposed machinery parts. These fixed-position nozzles typically feature precision-machined tips that deliver consistent flow patterns, ensuring uniform lubricant distribution across bearing surfaces and gear assemblies. The rigid design withstands repeated use without bending or deformation, particularly important in high-volume manufacturing environments where maintenance technicians perform hundreds of lubrication cycles daily. Flexible nozzles represent another essential category, designed specifically for hard-to-reach machinery components. These bendable extensions allow operators to navigate around obstacles, reach recessed lubrication points, and access confined spaces within complex equipment assemblies. The High-Pressure Oil Can equipped with flexible nozzles proves invaluable in automotive assembly lines, aerospace maintenance facilities, and heavy machinery servicing where direct line-of-sight access is often impossible. Modern flexible nozzles incorporate durable materials that maintain their shape after bending while resisting kinking or cracking under pressure, ensuring reliable performance throughout extended service intervals.

Precision Tip Nozzles for Targeted Lubrication

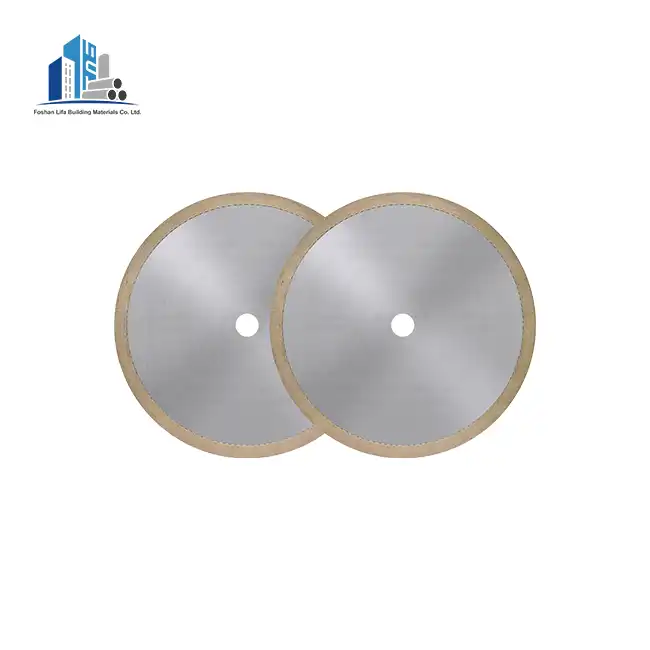

Precision tip nozzles represent the pinnacle of controlled lubrication technology in High-Pressure Oil Can design. These specialized nozzles feature ultra-fine orifices that deliver precise oil quantities directly to specific friction points without excess spillage or waste. In manufacturing environments where contamination control is paramount, precision tips prevent over-lubrication that could attract dust particles or interfere with product quality. The narrow discharge pattern enables technicians to lubricate closely-spaced components without affecting adjacent parts, particularly crucial in electronics manufacturing and food processing equipment where lubricant migration must be strictly controlled. The engineering behind precision tip nozzles incorporates multiple design considerations to ensure optimal performance under high-pressure conditions. Material selection focuses on corrosion-resistant alloys, typically high-grade brass or stainless steel, that maintain dimensional stability despite repeated pressure cycles reaching 6000 PSI or higher. The orifice geometry undergoes precision machining to create consistent flow characteristics, eliminating variations that could result in uneven lubricant distribution. Advanced High-Pressure Oil Can systems integrate replaceable precision tips, allowing maintenance teams to switch between different orifice sizes based on specific machinery requirements without replacing the entire lubrication tool.

Spray Pattern Nozzles for Broader Coverage

Spray pattern nozzles serve distinct purposes in industrial lubrication programs where broader coverage is required compared to pinpoint precision. These nozzles atomize lubricant into fine droplets distributed across wider surface areas, making them particularly effective for chain lubrication, open gear systems, and large bearing assemblies. The High-Pressure Oil Can fitted with spray pattern nozzles reduces application time significantly when servicing equipment with multiple lubrication points in close proximity, improving maintenance efficiency without compromising coverage quality. Different spray angles characterize various nozzle designs, ranging from narrow concentrated patterns to wide fan distributions. Narrow-angle spray nozzles, typically operating between 15 to 30 degrees, focus lubricant delivery while still providing better coverage than rigid tips alone. These configurations excel in applications like conveyor systems where multiple rollers require lubrication along extended runs. Wide-angle spray patterns, exceeding 60 degrees in some designs, facilitate rapid lubrication of large surface areas such as slide ways, press beds, and other extensive metal-to-metal contact zones. The High-Pressure Oil Can system pressure directly influences spray pattern formation, with higher pressures producing finer atomization and more uniform distribution across the target surface.

Industrial Applications of High-Pressure Oil Can Nozzles

Manufacturing facilities represent the primary environment where High-Pressure Oil Can nozzles demonstrate their critical value in maintaining operational continuity. In automotive assembly plants, robotic welding stations require frequent lubrication of articulation points, servo motors, and linear actuators to prevent premature wear under continuous operation cycles. Maintenance technicians rely on flexible nozzle configurations to access lubrication fittings positioned within tight spaces between robotic arms and work cells, where rigid tools cannot reach effectively. The precision delivery enabled by specialized High-Pressure Oil Can nozzles minimizes lubricant consumption while maximizing equipment uptime, directly impacting production efficiency and cost management. Heavy machinery operations in construction and mining sectors present particularly demanding lubrication challenges requiring robust nozzle solutions. Excavators, bulldozers, and drilling equipment operate in harsh environmental conditions with extreme dust, moisture, and temperature variations that accelerate component wear. The High-Pressure Oil Can equipped with durable, sealed nozzle designs delivers lubricant effectively even when contaminated with abrasive particles or exposed to weather elements. Extended-reach nozzles enable operators to service elevated lubrication points on large equipment without requiring ladders or lifts, improving both safety and maintenance efficiency. In underground mining applications where space is severely restricted, compact High-Pressure Oil Can systems with multi-angle nozzles provide essential lubrication capabilities despite challenging access constraints.

Aerospace Maintenance Requirements

Aerospace maintenance facilities impose stringent requirements on lubrication equipment, including High-Pressure Oil Can nozzle specifications that meet aviation safety and quality standards. Aircraft hydraulic systems, landing gear assemblies, and flight control mechanisms demand contamination-free lubrication delivered with absolute precision to prevent system failures during critical flight operations. Specialized nozzles designed for aerospace applications incorporate features like built-in filters preventing particulate introduction, certification-compliant materials resistant to aviation fluids, and precise flow controls ensuring correct lubricant quantities according to manufacturer specifications. The High-Pressure Oil Can utilized in aerospace contexts must accommodate various lubricant viscosities ranging from light hydraulic fluids to heavy-duty greases, requiring interchangeable nozzle systems that maintain consistent performance across different fluid properties. Maintenance procedures often specify exact nozzle types for particular aircraft components, with documentation tracing lubrication activities to specific equipment serial numbers. This level of precision demands High-Pressure Oil Can systems with clearly marked, easily identifiable nozzle configurations that prevent application errors potentially compromising flight safety. Regular nozzle inspection and replacement schedules form integral parts of aerospace maintenance programs, ensuring lubrication equipment reliability matches the exacting standards applied to aircraft themselves.

Power Generation Facility Lubrication

Power generation facilities, whether conventional thermal plants or renewable energy installations, depend on reliable High-Pressure Oil Can systems for maintaining turbines, generators, and auxiliary equipment critical to continuous energy production. Steam turbine bearings operating at elevated temperatures require high-temperature-resistant nozzles that deliver specialized synthetic lubricants without degradation or leakage. The High-Pressure Oil Can nozzles used in these applications incorporate advanced sealing technologies and heat-resistant materials maintaining integrity despite prolonged exposure to temperatures exceeding standard operating ranges in typical industrial environments. Wind turbine maintenance presents unique challenges requiring specialized High-Pressure Oil Can configurations designed for high-altitude service under variable weather conditions. Technicians accessing nacelle-mounted gearboxes and generator bearings hundreds of feet above ground rely on lightweight, portable lubrication systems with secure-grip nozzles preventing accidental drops during servicing operations. Extended flexible nozzles enable access to internal lubrication points without requiring complete equipment disassembly, reducing maintenance time and associated production losses. The High-Pressure Oil Can systems deployed in renewable energy applications increasingly incorporate environmental considerations, utilizing biodegradable lubricants delivered through nozzles engineered to prevent environmental contamination in sensitive installation locations.

Selecting the Right Nozzle Configuration

Choosing appropriate High-Pressure Oil Can nozzle configurations requires systematic evaluation of multiple operational parameters including machinery design, accessibility constraints, lubricant properties, and maintenance frequency requirements. Equipment manufacturers typically provide lubrication specifications detailing recommended oil types, application quantities, and service intervals, forming the foundation for nozzle selection decisions. Maintenance engineers must consider whether precision point lubrication or broader spray coverage better serves specific machinery components, understanding that incorrect nozzle choice can result in either inadequate lubrication causing premature wear or excessive application creating contamination issues and unnecessary lubricant waste. Machinery accessibility significantly influences High-Pressure Oil Can nozzle requirements, with confined spaces, elevated positions, and obstructed lubrication points demanding flexible or extended-reach configurations. Assessment of service environment conditions including temperature extremes, chemical exposures, and contamination levels guides material selection for nozzle construction, ensuring durability under actual operating conditions. The High-Pressure Oil Can system itself must generate sufficient pressure to overcome resistance through extended nozzle lengths while maintaining adequate flow rates for effective lubrication. At Foshan Lifa Building Materials Co., Ltd., our High-Pressure Oil Can products feature maximum operating pressures up to 6000 PSI with interchangeable flexible precision-tip nozzles, providing versatile solutions adaptable to diverse industrial lubrication requirements across multiple sectors.

Material and Durability Considerations

High-Pressure Oil Can nozzle materials directly impact service life, corrosion resistance, and compatibility with various lubricant chemistries encountered in industrial applications. Brass nozzles offer excellent machinability enabling precise orifice dimensions while providing adequate corrosion resistance for standard petroleum-based lubricants. However, synthetic lubricants containing aggressive additives or operations involving exposure to cleaning solvents may require stainless steel construction for extended service intervals. The High-Pressure Oil Can nozzles manufactured from high-grade steel, such as those featured in our product line, combine exceptional durability with pressure-handling capability, withstanding repeated use in demanding industrial environments without dimensional changes affecting flow characteristics. Nozzle tip geometry requires particular attention, as this critical feature determines lubricant delivery patterns and application effectiveness. Machined tips maintain sharp edges and precise orifice dimensions ensuring consistent spray patterns throughout extended service periods, while stamped or formed tips may exhibit variability affecting performance predictability. The High-Pressure Oil Can systems incorporating full-copper nozzle components, as featured in our standard configurations, ensure smooth oil flow without internal restrictions that could impede delivery or create pressure fluctuations during operation. Surface treatments including chrome plating or specialized coatings enhance wear resistance and facilitate cleaning, important considerations in food-grade applications or cleanroom environments where hygiene standards prohibit contaminated lubrication equipment use.

Maintenance and Performance Optimization

Proper High-Pressure Oil Can nozzle maintenance directly correlates with lubrication system reliability and equipment protection effectiveness. Regular nozzle inspection identifies wear patterns, blockages, or damage compromising performance before these issues result in machinery lubrication failures. Maintenance protocols should include visual examination of nozzle tips for erosion or deformation, particularly after servicing abrasive environments or handling contaminated lubricants. The High-Pressure Oil Can nozzle components require periodic cleaning to remove residual lubricant deposits and accumulated debris that could restrict flow or alter spray patterns, with cleaning frequency adjusted based on lubricant type and application environment cleanliness. Performance testing ensures High-Pressure Oil Can nozzles maintain specified flow rates and pressure capabilities throughout their service life. Simple field tests involve comparing oil delivery quantities against manufacturer specifications, identifying nozzles requiring replacement before they compromise machinery lubrication adequacy. Systematic replacement schedules based on usage hours or application cycles prevent unexpected nozzle failures during critical maintenance operations. The High-Pressure Oil Can systems from Foshan Lifa Building Materials Co., Ltd. incorporate durable construction designed for extended service intervals, with readily available replacement nozzles supporting efficient maintenance programs. Our sealed structure design prevents oil leakage while protecting internal components from contamination, significantly extending reliable service life compared to conventional designs lacking proper sealing features.

Conclusion

Understanding High-Pressure Oil Can nozzle types and applications is fundamental to effective industrial maintenance programs. Proper nozzle selection, combined with regular maintenance and performance monitoring, ensures reliable equipment lubrication protecting your valuable machinery investments while optimizing operational efficiency.

Cooperate With Foshan Lifa Building Materials Co., Ltd.

Foshan Lifa Building Materials Co., Ltd. stands ready as your trusted partner for premium High-Pressure Oil Can solutions backed by over a decade of manufacturing excellence. Our mature R&D team continuously develops innovative lubrication tools meeting evolving industrial demands, while our GMP-certified factory ensures consistent quality through rigorous production controls. With extensive inventory supporting immediate shipment, complete international certifications including ISO 9001:2015 and CE compliance, plus competitive pricing reflecting our cost advantages, we deliver exceptional value to global customers. Our experienced staff provides expert guidance on product selection and application requirements, supported by professional communication ensuring your needs are fully understood and addressed. Whether you require standard configurations or customized OEM solutions tailored to specific applications, our in-house design team collaborates closely with clients creating optimal lubrication tools for unique operational requirements. Contact us today at wz@jiancaiqy.com to discuss your High-Pressure Oil Can requirements and discover how our comprehensive capabilities and customer-focused service can enhance your maintenance programs—bookmark this resource for future reference whenever lubrication challenges arise.

References

1. Danfoss Heating Solutions, "Oil Burner Nozzles Technical Specifications and Application Guidelines," Industrial Equipment Standards Documentation

2. Society of Tribologists and Lubrication Engineers, "High-Pressure Lubrication Systems in Industrial Applications," Journal of Applied Lubrication Technology

3. International Standards Organization, "ISO 9001:2015 Quality Management Systems for Industrial Tool Manufacturing," Quality Assurance Standards Publication

4. National Institute for Occupational Safety and Health, "Best Practices for Industrial Machinery Lubrication and Maintenance Safety," Workplace Safety Guidelines

5. American Society of Mechanical Engineers, "Precision Lubrication Equipment Design and Performance Standards," ASME Technical Standards Committee

Learn about our latest products and discounts through SMS or email