- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Industrial-Grade Electric Mixer Cost vs Performance: Which Wins?

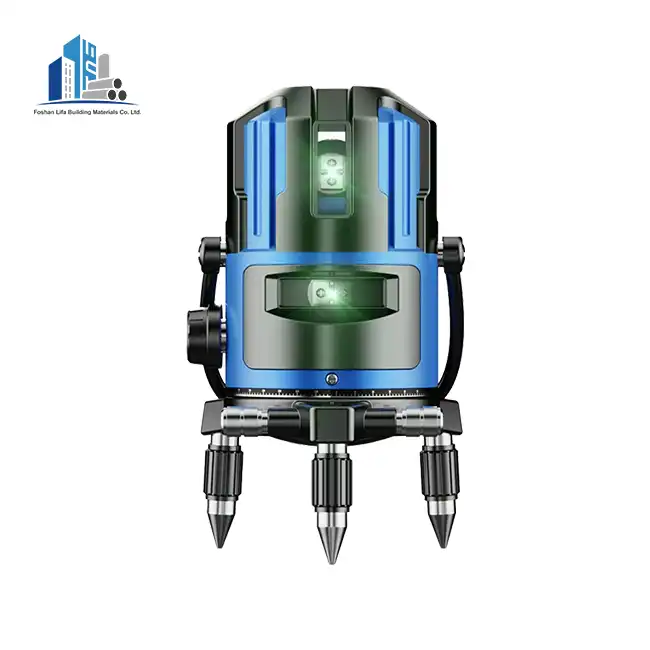

When production demands escalate and mixing quality becomes non-negotiable, industrial facilities face a critical decision: should you prioritize upfront savings or long-term operational excellence? For manufacturers processing high-viscosity materials, pharmaceutical compounds, or construction adhesives, choosing the wrong Industrial-Grade Electric Mixer can mean costly downtime, inconsistent product quality, and frustrated production teams. This comprehensive analysis examines the true cost-performance balance, helping you make an informed investment decision that maximizes productivity while controlling expenses.

Understanding the Real Cost of Industrial-Grade Electric Mixer Investment

The purchase price displayed on a quotation represents merely the beginning of your Industrial-Grade Electric Mixer's financial impact. Smart procurement managers recognize that total cost of ownership extends far beyond the initial transaction. When evaluating mixer investments, you must account for installation expenses, operator training requirements, energy consumption patterns, maintenance schedules, spare parts availability, and potential production losses during equipment failures. A seemingly affordable unit with inferior motor construction or inadequate heat dissipation systems may require replacement within three years, while a properly engineered Industrial-Grade Electric Mixer from a reputable manufacturer can deliver reliable performance for over fifteen years. The key lies in understanding how component quality directly correlates with operational longevity and consistent mixing results across thousands of production cycles.

Initial Purchase Price vs Long-Term Value

Budget-conscious buyers often gravitate toward lower-priced mixing equipment without fully analyzing the performance specifications that justify premium pricing. An Industrial-Grade Electric Mixer equipped with a high-power all-copper wire motor, electronic stepless speed regulation, and circulating heat dissipation systems costs significantly more than basic models featuring aluminum windings and fixed-speed operation. However, the superior model delivers precise viscosity control across diverse materials, prevents motor overheating during extended mixing sessions, and maintains consistent torque under heavy loads. These capabilities translate directly into reduced batch rejection rates, minimized equipment downtime, and elimination of costly production delays. Manufacturing facilities processing materials ranging from fifty to one thousand liters per batch particularly benefit from mixers offering five to twenty horsepower capacity with speed ranges adjustable from fifty to fifteen hundred RPM, ensuring optimal mixing performance regardless of material viscosity or processing requirements.

Operating Costs and Energy Efficiency Considerations

Electricity consumption represents a substantial ongoing expense that dramatically impacts your Industrial-Grade Electric Mixer's total cost of ownership. Units engineered with variable frequency drives and optimized motor efficiency consume thirty to forty percent less power compared to older fixed-speed designs while delivering equivalent or superior mixing performance. For facilities operating multiple mixing stations across two or three production shifts daily, these energy savings compound into significant annual cost reductions. Additionally, efficient motor designs generate less waste heat, reducing cooling system demands and creating more comfortable working environments for operators. When comparing competing Industrial-Grade Electric Mixer options, request detailed specifications including rated power consumption at various load levels, power factor ratings, and motor efficiency certifications. Manufacturers adhering to ISO 9001 quality management standards typically provide comprehensive performance documentation that enables accurate operating cost projections over the equipment's expected service life.

Performance Factors That Define Mixing Excellence

An Industrial-Grade Electric Mixer's true value emerges through its ability to consistently deliver specified mixing results across diverse materials and production conditions. Performance encompasses multiple interrelated factors including motor torque characteristics, speed control precision, blade design efficiency, structural rigidity, and thermal management capabilities. Superior performance means your mixing equipment maintains consistent results whether processing light emulsions at high speeds or handling dense adhesives requiring substantial torque at lower RPMs. The electronic stepless speed regulation available in advanced Industrial-Grade Electric Mixer models allows operators to precisely dial in optimal speeds for each specific material, eliminating the compromise inherent in fixed-speed or stepped-speed systems. This precision directly impacts product quality consistency, reduces material waste from over-processing or inadequate mixing, and shortens production cycle times by enabling immediate speed adjustments rather than batch-to-batch experimentation.

Motor Power and Torque Delivery Systems

The heart of any Industrial-Grade Electric Mixer lies in its motor design and power transmission system. High-quality units feature motors wound with pure copper wire rather than aluminum alternatives, delivering superior electrical conductivity, enhanced thermal performance, and extended operational lifespan. Copper-wound motors maintain consistent torque output even when processing high-viscosity materials that would cause aluminum-wound competitors to overheat and fail. The motor's continuous duty rating proves equally critical—industrial applications demand equipment capable of sustained operation rather than intermittent use patterns typical of consumer-grade tools. An Industrial-Grade Electric Mixer designed for chemical processing, pharmaceutical manufacturing, or construction material production must deliver rated performance throughout eight-hour shifts without thermal degradation or power output reduction. Additionally, advanced models incorporate circulating heat dissipation systems that actively manage motor temperatures, preventing the overheating and burnout that plague cheaper alternatives while ensuring the equipment remains comfortable for operators to handle during extended production runs.

Speed Control and Application Versatility

Mixing requirements vary dramatically across industries and even within individual production facilities processing diverse material formulations. An Industrial-Grade Electric Mixer equipped with electronic stepless speed regulation provides unmatched versatility, enabling operators to select any speed point within the equipment's range rather than choosing from predetermined fixed settings. This capability proves essential when processing materials spanning from low-viscosity paints requiring high-speed dispersion to thick adhesives demanding high-torque, low-speed mixing. The speed range itself significantly impacts application suitability—units offering fifty to fifteen hundred RPM accommodate virtually all industrial mixing needs, whereas limited-range models restrict processing flexibility. Moreover, precise speed control directly influences product quality consistency, allowing operators to replicate successful mixing parameters across multiple production batches with minimal variation. For facilities requiring ISO certification or operating under strict quality management protocols, the documented repeatability enabled by electronic speed regulation systems represents a critical compliance advantage that justifies the associated cost premium over basic on-off switching or mechanical speed control alternatives.

Design Features That Enhance Operational Efficiency

Beyond raw power specifications, thoughtful design features significantly impact an Industrial-Grade Electric Mixer's practical usability and operator productivity. The symmetrical auxiliary handle configuration found on well-engineered units enables stable two-hand operation, reducing operator fatigue during extended mixing sessions while improving control precision. The 360-degree rotatable rear seat provides multi-angle operational flexibility, allowing technicians to position the equipment optimally for different container configurations without wrestling against fixed mounting orientations. These ergonomic considerations may appear minor compared to motor specifications, but they directly influence operator comfort, reduce physical strain, and enable more precise mixing technique application. Facilities prioritizing workplace safety and employee satisfaction recognize that equipment designed with operator needs in mind delivers better long-term value through reduced injury risks, lower turnover rates among skilled technicians, and enhanced productivity as experienced operators work more efficiently with well-designed tools.

Durability and Construction Quality Standards

Material selection and manufacturing precision fundamentally determine an Industrial-Grade Electric Mixer's operational lifespan and maintenance requirements. Premium units constructed from 304 or 316 grade stainless steel offer exceptional corrosion resistance essential for food processing, pharmaceutical production, and chemical manufacturing applications where equipment contacts diverse materials throughout its service life. The stainless steel construction withstands aggressive cleaning protocols, resists chemical attack from processing materials, and maintains structural integrity under mechanical stresses that would deform or crack inferior materials. Reinforced mounting brackets, precision-machined drive components, and quality bearings further contribute to equipment longevity, enabling thousands of operational hours without significant wear or performance degradation. Manufacturers supporting their Industrial-Grade Electric Mixer products with comprehensive certifications including ISO 9001 quality management, CE conformity marking, and RoHS compliance demonstrate commitment to manufacturing excellence and provide customers with documented assurance that equipment meets rigorous international standards for safety, performance, and environmental responsibility.

Strategic Procurement Considerations for Industrial Buyers

Selecting the optimal Industrial-Grade Electric Mixer requires balancing immediate budget constraints against long-term operational requirements and total cost of ownership projections. Procurement specialists should develop comprehensive evaluation criteria encompassing technical specifications, manufacturer reputation, after-sales support capabilities, spare parts availability, and warranty terms. Engaging with suppliers offering OEM and ODM customization services enables equipment tailoring to specific application requirements, potentially eliminating compromises inherent in standard catalog products. For example, facilities processing unique material formulations may benefit from custom blade designs, modified speed ranges, or specialized sealing systems that standard Industrial-Grade Electric Mixer configurations cannot accommodate. Additionally, establishing relationships with manufacturers maintaining substantial spare parts inventories and providing responsive technical support minimizes downtime risks when service requirements arise. The most sophisticated buyers recognize that equipment acquisition represents the beginning rather than the conclusion of the supplier relationship, making manufacturer stability, engineering expertise, and customer service quality equally important as initial equipment specifications and pricing.

Customization Options and OEM Capabilities

Standard Industrial-Grade Electric Mixer offerings serve most applications adequately, but specialized processing requirements often demand customized solutions that off-the-shelf equipment cannot provide. Manufacturers with strong research and development capabilities and flexible production systems can modify motor power ratings, adjust speed ranges, incorporate specialized sealing systems, or engineer custom blade configurations addressing specific material processing challenges. These customization services prove particularly valuable for facilities processing proprietary formulations, operating under unique regulatory requirements, or integrating mixing equipment into automated production lines requiring specific control interfaces. The ability to specify voltage configurations matching existing facility electrical infrastructure eliminates costly power system modifications, while custom mounting arrangements facilitate installation into space-constrained production areas. When evaluating potential suppliers, inquire about minimum order quantities for customized Industrial-Grade Electric Mixer configurations, engineering support availability during specification development, and typical lead times from order placement through equipment delivery. Suppliers serving global markets across thirty-plus countries typically possess the engineering depth and production flexibility necessary to accommodate customization requests efficiently while maintaining quality standards.

Conclusion

Balancing Industrial-Grade Electric Mixer cost against performance requires comprehensive analysis beyond purchase price alone, encompassing operational efficiency, durability, and long-term value delivery that truly defines equipment investment wisdom.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Partner with Foshan Lifa Building Materials Co., Ltd., your trusted China Industrial-Grade Electric Mixer manufacturer, China Industrial-Grade Electric Mixer supplier, and China Industrial-Grade Electric Mixer factory delivering premium quality at competitive Industrial-Grade Electric Mixer prices. Our High Quality Industrial-Grade Electric Mixer inventory ensures immediate Industrial-Grade Electric Mixer for sale availability, backed by comprehensive OEM support, rigorous quality certifications, and expert technical guidance. With mature R&D capabilities, extensive product selection spanning hardware tools and power equipment, and proven service excellence across thirty-plus international markets, we transform your mixing challenges into production advantages. Contact our experienced team at wz@jiancaiqy.com for customized China Industrial-Grade Electric Mixer wholesale solutions perfectly matched to your application requirements.

References

1. "Considerations When Choosing Pneumatic vs. Electric Industrial Mixing Equipment" by INDCO Engineering Team, PCI Magazine, 2023.

2. "Industrial Mixer Selection and Total Cost of Ownership Analysis" by MXD Process Engineering Department, Industrial Equipment Review, 2024.

3. "Performance Comparison of Electric vs. Gas-Powered Industrial Mixing Systems" by PDQuipment Technical Division, Construction Equipment Journal, 2025.

4. "Price Points and Value Analysis for Industrial Mixing Equipment" by INDCO Research Team, Industrial Mixing Technology, 2021.

5. "Motor Technology and Energy Efficiency in Commercial Mixing Applications" by Hobart Food Equipment Engineering, Commercial Kitchen Technology, 2024.

Learn about our latest products and discounts through SMS or email