- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

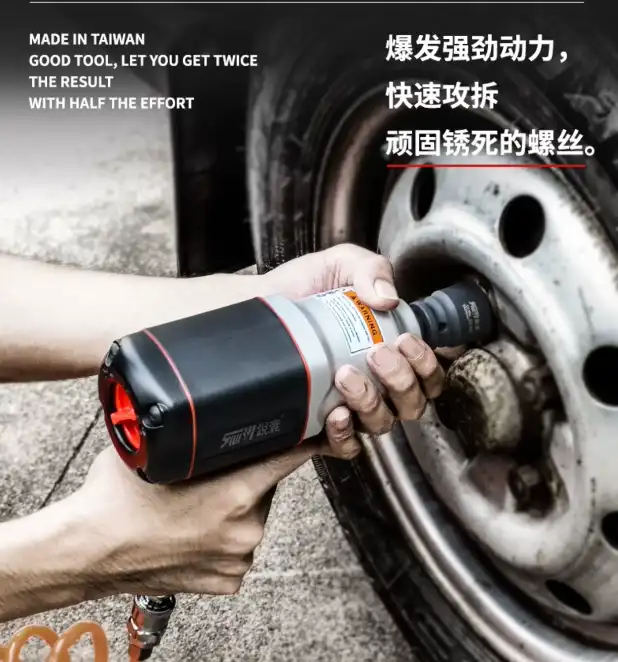

Industrial Grade Pneumatic Wrench Applications Across Industries

When assembly lines slow down due to inefficient fastening tools, production costs skyrocket and deadlines slip. Industrial Grade Pneumatic Wrench technology addresses these critical pain points by delivering consistent high-torque performance that transforms operational efficiency. This comprehensive guide explores how pneumatic wrenches revolutionize fastening operations across multiple industrial sectors, offering practical insights for professionals seeking to optimize their tooling investments.

Understanding Industrial Grade Pneumatic Wrench Technology

The fundamental engineering behind an Industrial Grade Pneumatic Wrench centers on compressed air power conversion into rotational torque. Unlike electric alternatives, pneumatic systems harness compressed air to drive internal hammer mechanisms that strike anvils repeatedly, generating powerful impacts. This design philosophy delivers exceptional torque-to-weight ratios while maintaining operator comfort during extended use. Modern industrial-grade units incorporate dual-hammer striking designs manufactured from military-grade materials, ensuring ultra-high strength, toughness, and wear resistance that withstands the harshest working conditions. The extended motor design featured in premium Industrial Grade Pneumatic Wrench models enables full power delivery, with output torque reaching up to 2000 Nm in advanced configurations. These specifications make them indispensable for heavy-duty applications where conventional tools fail. The ergonomic handle with soft rubber grip ensures comfortable holding during prolonged operations, reducing operator fatigue significantly. Additionally, the 360° universal air inlet connector prevents air hose tangling and reduces connector wear, extending tool lifespan while improving workplace safety through better hose management.

Key Performance Specifications

Professional-grade pneumatic wrenches typically operate at free speeds between 5000-7000 RPM with air consumption ratings around 280 L/min at standard pressure. Weight considerations remain crucial, with industrial models ranging from 8.5 to 12 kg depending on drive size and torque capacity. Noise levels are carefully engineered to remain below 85 dB, complying with occupational health standards, while vibration levels stay under 2.5 m/s² to minimize hand-arm vibration syndrome risks. These specifications reflect decades of refinement in pneumatic tool design, balancing raw power with user-centric ergonomics.

Automotive Manufacturing and Repair Applications

Within automotive manufacturing environments, the Industrial Grade Pneumatic Wrench serves as the backbone of assembly line efficiency. Production facilities utilize these tools for chassis assembly, engine mounting, suspension installation, and drivetrain component fastening. The consistent torque output ensures each fastener meets exact specifications, critical for vehicle safety and performance. Automotive repair shops depend on pneumatic impact wrenches for tire changing operations, brake system maintenance, transmission work, and engine overhauls. The rapid nut-busting capabilities significantly reduce service time, directly improving shop profitability and customer satisfaction. The precision control offered by advanced Industrial Grade Pneumatic Wrench models prevents over-torquing that could strip threads or damage sensitive components. This accuracy proves particularly valuable when working with aluminum engine blocks, composite materials, and modern lightweight automotive structures. Professional technicians appreciate the tool's ability to transition seamlessly from high-impact operation to gentle driving modes as torque requirements change during fastener engagement. This versatility makes a single pneumatic wrench suitable for diverse automotive applications, from delicate sensor installations to heavy-duty suspension bolts.

Specialized Automotive Applications

Racing teams and performance shops utilize high-torque pneumatic wrenches for quick pit-stop tire changes where seconds determine competitive advantage. The tools' reliability under pressure and consistent performance make them irreplaceable in motorsport applications. Similarly, heavy vehicle maintenance facilities serving commercial trucks, buses, and construction equipment rely on 1-inch and 1-1/2-inch drive pneumatic wrenches capable of handling massive fasteners with torque requirements exceeding 1500 Nm. These specialized applications demonstrate how Industrial Grade Pneumatic Wrench technology scales from passenger vehicles to heavy commercial equipment.

Construction and Steel Structure Assembly

Construction projects involving steel structure assembly depend heavily on Industrial Grade Pneumatic Wrench systems for connecting beams, columns, and structural elements. High-rise building construction requires thousands of bolted connections, each demanding precise torque application to ensure structural integrity. Pneumatic wrenches excel in these environments where electric tools would require constant battery changes or power cord management. The tools' ability to function reliably in dusty, outdoor conditions with temperature variations makes them ideal for construction site realities. Scaffolding installation and dismantling operations benefit tremendously from pneumatic impact technology. Workers can rapidly secure and release scaffolding connections, improving setup efficiency while maintaining safety standards. Bridge construction projects utilize specialized high-torque Industrial Grade Pneumatic Wrench models for connecting massive structural elements where torque requirements often exceed 3000 Nm. The tools' consistent performance regardless of ambient temperature proves invaluable during winter construction or hot summer conditions where hydraulic systems might experience viscosity changes.

Infrastructure Project Demands

Large infrastructure projects including highway construction, tunnel boring, and railway installations require fastening solutions that balance portability with industrial power. The Industrial Grade Pneumatic Wrench addresses this balance through compact designs that deliver impressive torque without requiring heavy hydraulic power packs. Maintenance crews working on existing infrastructure appreciate pneumatic tools for removing rusted or corroded fasteners that electric impact wrenches cannot handle. The sustained high-torque operation capability enables workers to tackle stubborn bolts without tool overheating or motor burnout concerns.

Oil and Gas Industry Applications

Within oil and gas operations, the Industrial Grade Pneumatic Wrench plays critical roles in pipeline assembly, wellhead installation, and refinery maintenance. Pipeline construction crews utilize these tools for flange bolting operations where uniform torque distribution ensures leak-proof connections. The tools' intrinsically safe operation in potentially explosive atmospheres makes them preferred over electric alternatives that could generate sparks. Offshore platform maintenance requires tools that withstand salt air corrosion and function reliably in harsh marine environments, requirements that industrial pneumatic wrenches meet through specialized coatings and sealed mechanisms. Drilling rig maintenance involves frequent equipment servicing where Industrial Grade Pneumatic Wrench systems enable quick turnaround times during critical operations. The ability to generate substantial torque for loosening drill string connections and casing couplings directly impacts operational efficiency. Refinery turnaround projects demand tools capable of continuous operation during intensive maintenance periods, and pneumatic wrenches deliver this reliability while maintaining consistent performance throughout extended shifts. The tools' simple mechanical design ensures field repairability, a crucial advantage in remote locations where specialized repair services remain unavailable.

Manufacturing and Heavy Equipment Sectors

Manufacturing assembly lines across industries from aerospace to heavy machinery depend on Industrial Grade Pneumatic Wrench technology for consistent, repeatable fastening operations. Production environments benefit from pneumatic tools' longer operational life compared to electric alternatives, reducing downtime and maintenance costs. The tools integrate seamlessly with existing compressed air infrastructure common in manufacturing facilities, eliminating additional power supply investments. Quality control systems can precisely calibrate pneumatic wrenches to specific torque values, ensuring every assembled product meets engineering specifications. Heavy equipment manufacturers building excavators, cranes, bulldozers, and mining machinery utilize specialized high-torque pneumatic wrenches for final assembly operations. These applications often involve large-diameter fasteners requiring torques between 1000-2500 Nm, territory where Industrial Grade Pneumatic Wrench systems excel. The tools' vibration-dampening designs protect operators during extended use while maintaining productivity levels. Maintenance operations for existing heavy equipment fleets also rely heavily on pneumatic impact technology for component replacement and overhaul procedures.

Shipbuilding and Marine Applications

Shipyards employ Industrial Grade Pneumatic Wrench tools throughout vessel construction, from hull assembly to engine installation and deck fitting. The marine environment's corrosive nature demands tools with superior durability, and industrial pneumatic wrenches meet this challenge through specialized surface treatments and stainless steel components. Ship repair facilities utilize these tools for maintenance operations ranging from propeller shaft work to superstructure modifications. The tools' ability to function in confined spaces common aboard vessels makes them particularly valuable for marine applications where access limitations constrain tool selection.

Conclusion

Industrial Grade Pneumatic Wrench systems deliver unmatched performance across diverse industrial applications, combining power, reliability, and operational efficiency. Their proven track record in automotive, construction, oil and gas, manufacturing, and marine sectors demonstrates their versatility and value as essential industrial tools.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

As a trusted China Industrial Grade Pneumatic Wrench factory, China Industrial Grade Pneumatic Wrench supplier, and China Industrial Grade Pneumatic Wrench manufacturer, Foshan Lifa Building Materials Co., Ltd. offers comprehensive China Industrial Grade Pneumatic Wrench wholesale solutions. Our Industrial Grade Pneumatic Wrench for sale features competitive Industrial Grade Pneumatic Wrench price points without compromising quality. Every High Quality Industrial Grade Pneumatic Wrench undergoes rigorous testing to meet ISO9001, ASTM, and DIN standards, ensuring reliable performance for your operations.

With over 15 years of industry expertise, our professional R&D team continuously innovates to meet evolving market demands. We maintain extensive inventory for immediate shipping, backed by flexible OEM/ODM services tailored to your specifications. Our 50,000 square meter manufacturing facility employs advanced production technologies and strict quality control throughout the manufacturing process. Serving clients across 30+ countries including South America, EU, Australia, Middle East, and Southeast Asia, we've established ourselves as a reliable supply chain partner for international distributors and engineering contractors.

Ready to enhance your operational efficiency? Contact us at wz@jiancaiqy.com for detailed product specifications, competitive quotations, and customized solutions. Save this page for easy reference when making your procurement decisions—our experienced team stands ready to provide expert guidance for your specific application requirements.

References

1. "Pneumatic Torque Tools: Design and Industrial Applications" - American Society of Mechanical Engineers (ASME), Torque Tool Technology Committee

2. "Industrial Fastening Systems: Performance Standards and Best Practices" - International Organization for Standardization (ISO) Technical Committee TC29/SC10

3. "Compressed Air Tools in Manufacturing Environments: Efficiency and Safety Analysis" - National Institute for Occupational Safety and Health (NIOSH) Engineering Controls Research Branch

4. "Heavy-Duty Bolting Technology for Oil and Gas Operations" - American Petroleum Institute (API) Equipment Standards Division

5. "Automotive Assembly Line Tool Performance: A Comparative Study of Pneumatic vs. Electric Impact Wrenches" - Society of Automotive Engineers (SAE) International, Manufacturing Technology Division

Learn about our latest products and discounts through SMS or email