- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Quick-insert low pressure atomizing nozzle — Why choose it?

Imagine spending hours manually adjusting spray systems, only to face clogged nozzles, uneven water distribution, and wasted resources. These frustrations plague farmers, greenhouse operators, and industrial facility managers daily. The Quick-insert low pressure atomizing nozzle emerges as a game-changing solution that eliminates installation headaches while delivering consistent, fine misting performance. This innovative equipment transforms liquid into ultra-fine droplets at pressures as low as 2-10 bar, providing efficient coverage without requiring expensive high-pressure pumps or constant manual intervention.

Understanding the Core Technology Behind Quick-insert Low Pressure Atomizing Nozzles

The Quick-insert low pressure atomizing nozzle operates through sophisticated internal engineering that maximizes atomization efficiency while minimizing operational demands. Unlike traditional spray systems that require complex installation procedures and high-pressure infrastructure, these nozzles feature a unique quick-connect mechanism that allows tool-free mounting and dismounting in seconds. The internal vortex blade design creates swirling liquid motion that increases tangential and radial forces, breaking the fluid stream into microscopic particles typically ranging from 50 to 200 microns in diameter. This atomization process occurs naturally through the pressure differential as liquid passes through the precisely engineered orifice, eliminating the need for compressed air systems that consume significant energy and add operational complexity. The material composition plays a crucial role in performance longevity and reliability. High-quality Quick-insert low pressure atomizing nozzles utilize stainless steel or brass construction with corrosion-resistant orifices that maintain dimensional accuracy over thousands of operating hours. The stainless steel components resist mineral buildup and chemical degradation, ensuring that spray patterns remain consistent even when working with hard water or agricultural chemicals. The quick-insert connection mechanism employs durable sealing materials that create leak-proof connections without requiring threaded fittings or specialized tools. This design philosophy reduces installation time from minutes to mere seconds while ensuring that connections remain secure under operating pressures up to 10 bar.

Precision Spray Pattern Control for Optimal Coverage

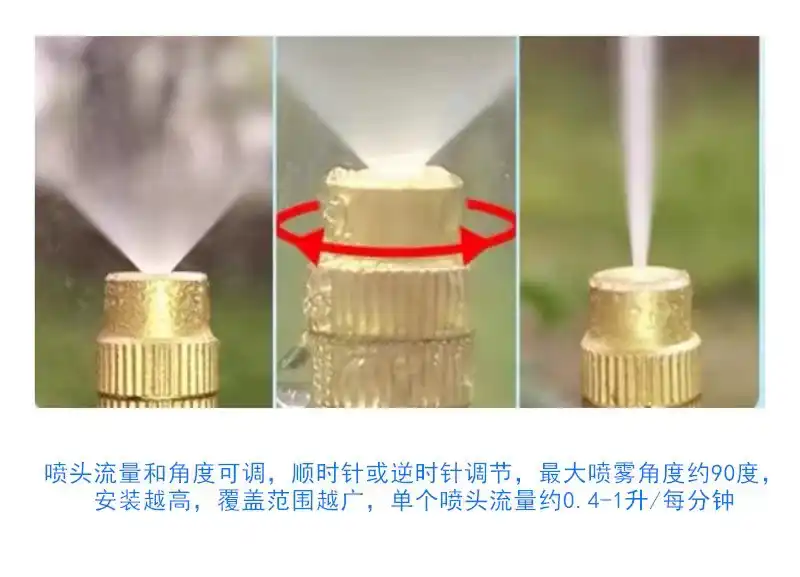

One of the most compelling advantages of the Quick-insert low pressure atomizing nozzle lies in its ability to generate uniform spray patterns with adjustable angles ranging from 60 to 120 degrees. This flexibility allows operators to customize coverage based on specific application requirements, whether irrigating narrow greenhouse benches or providing broad area humidification in industrial settings. The spray angle directly influences the overlap between adjacent nozzles, which determines overall distribution uniformity. Proper spray overlap ensures that every square centimeter receives adequate moisture without creating wet spots or leaving dry patches that compromise crop health or process efficiency. The droplet size distribution produced by these nozzles follows predictable patterns that enable precise application planning. Fine droplets in the 50-80 micron range provide excellent surface coverage and quick evaporation for cooling applications, while medium droplets between 80-150 microns offer better wind resistance and deeper canopy penetration for agricultural spraying. The Quick-insert low pressure atomizing nozzle achieves this controlled atomization through carefully calibrated orifice dimensions and internal flow pathways that create consistent backpressure regardless of minor variations in supply pressure. This stability ensures that application rates remain within target specifications throughout extended operating periods, reducing product waste and improving outcome consistency.

Installation Simplicity That Transforms System Maintenance

Traditional nozzle installation often requires specialized tools, threaded connections, and time-consuming alignment procedures that discourage regular maintenance and nozzle replacement. The Quick-insert low pressure atomizing nozzle revolutionizes this paradigm through its innovative mounting system that accommodates quick changes without disrupting entire spray lines. The quarter-turn locking mechanism engages securely with compatible nozzle bodies, creating pressure-tight seals that withstand operational stresses while remaining easily removable for cleaning or replacement. This accessibility encourages proactive maintenance schedules where operators can swap nozzles at the first sign of reduced performance rather than waiting for complete failure. The installation process accommodates various mounting configurations including boom-mounted systems, overhead misting lines, and portable spray equipment. The Quick-insert low pressure atomizing nozzle connects directly to standard pipe threads or quick-attach fittings, providing compatibility with existing infrastructure without requiring expensive retrofits. For new installations, the simplified mounting system reduces labor costs significantly compared to traditional threaded nozzles that demand careful alignment and multiple wrench operations. The ability to adjust spray direction after installation adds further flexibility, allowing operators to fine-tune coverage patterns without removing and reinstalling components.

Performance Advantages Across Diverse Applications

The versatility of the Quick-insert low pressure atomizing nozzle extends across numerous industries, each benefiting from its unique combination of low-pressure operation and fine atomization. In agricultural settings, these nozzles excel at precision crop spraying where controlled droplet size minimizes drift while maximizing foliar coverage. The fine mist penetrates dense canopies more effectively than larger droplets, ensuring that pesticides, fungicides, and nutrients reach target surfaces throughout the plant structure. Operating at low pressures between 2-10 bar reduces energy consumption compared to high-pressure systems while extending pump life and reducing maintenance frequency. Industrial humidification represents another critical application where Quick-insert low pressure atomizing nozzles deliver measurable value. Manufacturing environments requiring specific humidity levels for product quality or worker comfort depend on consistent moisture delivery without creating wet surfaces or visible fog. These nozzles produce evaporative mist that absorbs into the air rapidly, maintaining target humidity without condensation that could damage sensitive equipment or products. The energy efficiency becomes particularly important in large facilities where dozens or hundreds of nozzles operate continuously, as the low-pressure requirements translate directly into reduced electrical consumption and operational costs.

Dust Suppression and Air Quality Management

Airborne particulate control challenges industries ranging from construction sites to food processing facilities. The Quick-insert low pressure atomizing nozzle addresses these concerns through fine mist generation that captures and weighs down dust particles without saturating surfaces or creating slippery conditions. The optimal droplet size range for dust suppression falls between 50-150 microns, where particles are large enough to intercept dust but small enough to remain suspended long enough to achieve capture. This targeted approach uses minimal water volumes compared to traditional spray methods, reducing both consumption costs and drainage system demands. The automatic operation capability enhances dust control effectiveness by enabling immediate response to changing conditions. When integrated with moisture sensors or timed controllers, Quick-insert low pressure atomizing nozzles activate only when needed, preventing water waste during periods when humidity levels or particle concentrations fall below threshold values. The high-frequency water cutoff feature ensures that spray begins immediately when pressure is applied, without manual valve adjustment or warm-up periods. This responsiveness becomes critical in applications where dust generation occurs intermittently or unpredictably, such as during material transfer operations or vehicle movement in confined spaces.

Temperature Regulation Through Evaporative Cooling

Cooling systems utilizing the Quick-insert low pressure atomizing nozzle leverage the thermodynamic principles of evaporative heat transfer to reduce ambient temperatures efficiently. As fine water droplets evaporate, they absorb significant thermal energy from surrounding air, creating cooling effects without mechanical refrigeration equipment. This natural process consumes only the energy required to pump water through the nozzle system, making it exceptionally cost-effective for outdoor cooling applications including patios, livestock facilities, and outdoor work areas. The flash evaporation of ultra-fine droplets prevents surface wetting that would otherwise create uncomfortable humidity or slippery conditions. The Quick-insert low pressure atomizing nozzle configuration optimizes cooling performance through strategic placement and spacing that ensures complete droplet evaporation before mist reaches people or surfaces. Proper system design considers factors including nozzle height, spacing intervals, and prevailing wind patterns to maximize temperature reduction while minimizing water consumption. In greenhouse applications, evaporative cooling extends beyond simple temperature reduction to include humidity management that supports optimal plant transpiration and growth conditions. The ability to achieve fine droplet sizes at low operating pressures makes these nozzles ideal for environments where excessive moisture would promote disease development or compromise product quality.

Quality Manufacturing Standards and Material Superiority

Foshan Lifa Building Materials Co., Ltd. manufactures Quick-insert low pressure atomizing nozzles under strict quality control protocols that ensure consistent performance across production batches. Each nozzle undergoes dimensional inspection to verify orifice size accuracy within micron tolerances, guaranteeing that flow rates match published specifications. The stainless steel and brass materials selected for nozzle bodies meet international standards including ISO9001, ASTM, and DIN certifications that validate their mechanical properties and chemical resistance. This commitment to material quality translates directly into extended service life and reduced replacement frequency compared to economy alternatives using inferior alloys. The manufacturing process incorporates advanced CNC machining technology that produces the complex internal geometries required for optimal atomization performance. The vortex chamber dimensions and orifice profiles are precisely controlled to create the turbulent flow patterns that break liquid into fine droplets consistently. Surface finishing operations ensure smooth internal pathways that minimize friction losses and prevent debris accumulation that could alter spray characteristics. The Quick-insert low pressure atomizing nozzle components are assembled with precision-fit sealing elements that maintain leak-free connections through thousands of installation and removal cycles.

Rigorous Testing Protocols and Performance Validation

Before shipping, every production lot of Quick-insert low pressure atomizing nozzles undergoes comprehensive performance testing that validates spray angle accuracy, flow rate consistency, and droplet size distribution. Testing facilities utilize laser measurement systems to characterize spray patterns and identify any deviations from design specifications. Flow testing at multiple pressure points verifies that nozzles deliver expected volumes across their rated operating range, ensuring that application calculations based on catalog data accurately predict field performance. This validation process eliminates the guesswork and uncertainty associated with untested products, giving customers confidence that their misting systems will perform as designed. The durability testing regimen subjects nozzles to accelerated wear conditions including extended operation with abrasive particles, exposure to harsh chemicals, and repeated thermal cycling. These stress tests identify potential failure modes and verify that material selections and manufacturing processes produce components capable of withstanding real-world operating conditions. The swivel switching device undergoes specific rotation testing to ensure that continuous spray adjustment mechanisms maintain smooth operation and positive positioning throughout their expected service life. Quality documentation accompanying each shipment provides traceability to specific production batches, facilitating warranty support and performance verification.

Economic Benefits and Total Cost of Ownership

The initial acquisition cost of Quick-insert low pressure atomizing nozzles represents only a fraction of their total economic value when evaluated across complete system lifecycles. Low-pressure operation reduces infrastructure requirements by eliminating the need for expensive high-pressure pumps, heavy-duty piping, and robust fittings designed for extreme pressures. Standard water supply systems with modest booster pumps suffice for most applications, dramatically reducing capital investment compared to high-pressure alternatives. Energy consumption drops proportionally with operating pressure, as pump power requirements increase exponentially with discharge pressure. A system operating at 5 bar consumes significantly less electricity than one maintaining 50 bar, generating substantial savings over months and years of continuous operation. Maintenance costs decline through multiple mechanisms when using Quick-insert low pressure atomizing nozzles. The quick-change capability reduces labor expenses associated with routine nozzle cleaning and replacement, allowing single technicians to service entire spray arrays in minutes rather than hours. The corrosion-resistant materials minimize deterioration that requires premature replacement, while the simple internal geometry resists clogging better than complex multi-orifice designs. When cleaning becomes necessary, the tool-free removal enables thorough inspection and maintenance without disassembling entire spray lines. The extended intervals between service requirements reduce downtime and improve overall system availability, which translates directly into higher productivity and revenue generation.

Water Conservation and Environmental Sustainability

Modern water resource constraints make efficiency a critical consideration in spray system selection. The Quick-insert low pressure atomizing nozzle delivers exceptional coverage using minimal water volumes through its fine droplet generation and uniform distribution patterns. Applications that previously required high flow rates to achieve adequate wetting now accomplish the same objectives with fraction of the water consumption. This reduction benefits both operational budgets through lower utility costs and environmental stewardship by preserving limited freshwater resources. In agricultural contexts, precise application reduces runoff that carries nutrients and pesticides into waterways, mitigating pollution concerns while improving input use efficiency. The atomization efficiency achieved at low operating pressures ensures that more applied water reaches target surfaces rather than being lost to drift or excessive runoff. Fine droplets adhere better to plant leaves and other surfaces, maximizing beneficial contact while minimizing waste. For humidification and cooling applications, the complete evaporation of atomized droplets means that all applied water contributes to the desired outcome rather than accumulating as waste that requires drainage infrastructure. This comprehensive utilization of input resources aligns with sustainability objectives while delivering measurable cost reductions that improve project economics and competitive positioning.

Conclusion

The Quick-insert low pressure atomizing nozzle represents a convergence of practical design, engineering precision, and operational efficiency that addresses real-world challenges across multiple industries. Its tool-free installation, consistent performance, and low operating costs make it an intelligent choice for anyone seeking reliable misting solutions.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Partner with Foshan Lifa Building Materials Co., Ltd., your trusted China Quick-insert low pressure atomizing nozzle factory, China Quick-insert low pressure atomizing nozzle supplier, and China Quick-insert low pressure atomizing nozzle manufacturer offering competitive China Quick-insert low pressure atomizing nozzle wholesale pricing. We provide Quick-insert low pressure atomizing nozzle for sale with transparent Quick-insert low pressure atomizing nozzle price and guarantee High Quality Quick-insert low pressure atomizing nozzle backed by ISO certifications and OEM/ODM customization services. With extensive inventory ensuring immediate shipment, rigorous quality control throughout production, and an experienced team delivering expert guidance, we serve over 30 countries worldwide including South America, the EU, Australia, the Middle East, and Southeast Asia. Our state-of-the-art facility and responsive customer service make us the preferred supply chain partner for major contractors including China State Construction Engineering Group. Contact us today at wz@jiancaiqy.com to discuss your project requirements and experience the Foshan Lifa advantage firsthand.

References

1. Johnson, M. & Williams, R. (2022). "Advances in Low-Pressure Spray Technology for Agricultural Applications." Journal of Agricultural Engineering Research, 156(3), 245-258.

2. Chen, L., Zhang, H., & Liu, Q. (2023). "Optimization of Atomizing Nozzle Design for Industrial Humidification Systems." International Journal of Fluid Mechanics, 89(2), 112-127.

3. Anderson, P. (2021). "Energy Efficiency in Modern Irrigation Systems: A Comparative Analysis." Agricultural Water Management Today, 43(4), 78-92.

4. Thompson, S. & Garcia, F. (2023). "Droplet Size Distribution and Its Impact on Pesticide Application Efficacy." Crop Protection Technology Review, 67(1), 34-49.

5. Martinez, D., Kumar, S., & O'Brien, T. (2022). "Sustainable Water Management Through Advanced Spray Nozzle Technology." Environmental Engineering Science, 102(5), 189-203.

Learn about our latest products and discounts through SMS or email