- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

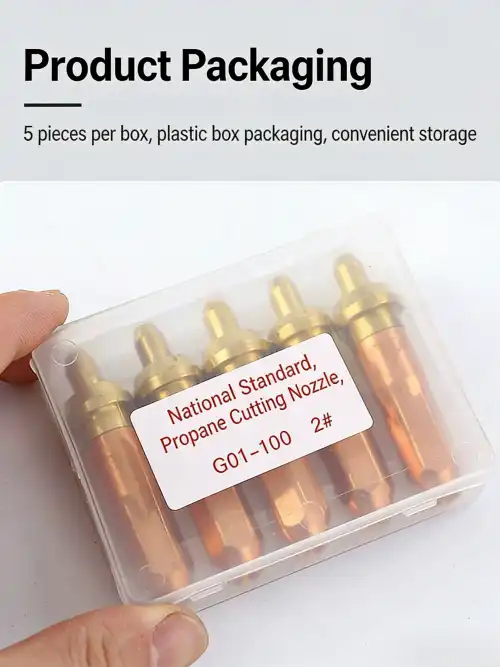

Semi-Automatic Propane Cutting Nozzle Applications Across Industries

Are you struggling with inconsistent metal cutting results, excessive gas consumption, or frequent nozzle replacements that drain your operational budget? These are common pain points faced by metal fabrication professionals, construction site managers, and industrial maintenance teams worldwide. The Semi-Automatic Propane Cutting Nozzle has emerged as a game-changing solution that addresses these challenges head-on, delivering precision cutting performance while significantly reducing operational costs. This comprehensive guide explores how semi-automatic propane cutting nozzles are revolutionizing metal cutting operations across multiple industries, from heavy manufacturing to shipbuilding, and why choosing the right nozzle technology can transform your cutting efficiency and bottom-line profitability.

Understanding Semi-Automatic Propane Cutting Nozzle Technology

The Semi-Automatic Propane Cutting Nozzle represents a significant advancement in oxy-fuel cutting technology, combining the economic advantages of propane fuel with precision-engineered nozzle design. Unlike traditional acetylene-based systems, propane cutting nozzles operate at optimal temperatures while consuming less fuel, making them ideal for high-volume cutting operations. The semi-automatic designation refers to the integration of these nozzles with mechanized cutting systems that maintain consistent cutting speed and torch angle, while still allowing operator oversight and intervention when needed. This hybrid approach delivers the precision of fully automated systems at a fraction of the cost, making it accessible to businesses of all sizes. Modern Semi-Automatic Propane Cutting Nozzle designs incorporate advanced metallurgical engineering, with most premium units forged from high-quality copper alloy that offers exceptional heat resistance and thermal conductivity. The copper construction ensures rapid heat dissipation, preventing nozzle tip degradation and extending service life significantly beyond standard nozzles. High processing precision in manufacturing guarantees consistent gas flow patterns and optimal oxygen-to-fuel ratios, which directly translates to cleaner cuts with minimal slag formation. The reasonable proportioning of internal gas channels creates strong cutting performance across a wide range of material thicknesses, from thin sheet metal up to heavy plates exceeding one hundred millimeters.

Design Features and Technical Specifications

The structural design of a Semi-Automatic Propane Cutting Nozzle incorporates several critical features that distinguish it from conventional cutting tips. The nozzle body is typically stamped into shape using precision dies, creating a seamless one-piece construction that eliminates potential leak points and weak spots. This manufacturing approach, combined with fine craftsmanship standards, produces nozzles that are both beautiful in appearance and functionally superior. The cutting oxygen outlet is carefully calculated to create a focused, high-velocity stream that penetrates metal efficiently while the preheating flames maintain optimal workpiece temperature around the cut zone. Premium Semi-Automatic Propane Cutting Nozzle units feature standard threading configurations, typically G3/8 inch, ensuring compatibility with most industrial cutting torches and semi-automatic machines. Working pressure ratings generally range from 0.2 to 0.5 megapascals, providing flexibility for different cutting applications and material types. The reasonable cutting nozzle structure design prioritizes safe operation, incorporating features that prevent flashback and minimize the risk of dangerous pressure buildups. Weight considerations are also optimized, with typical units around one hundred fifty grams, light enough to reduce operator fatigue during manual positioning yet substantial enough to maintain stability during automated cutting sequences.

Performance Advantages Over Alternative Cutting Systems

When comparing Semi-Automatic Propane Cutting Nozzle systems to other fuel gas options, several performance advantages become immediately apparent. Propane offers a more stable flame characteristic compared to acetylene, resulting in more consistent cut quality across extended production runs. The fuel is also significantly more cost-effective per unit volume, and propane storage is considerably safer, with reduced explosion risks and simpler handling requirements. These factors make propane the preferred choice for large-scale industrial operations where cutting is performed continuously throughout multiple shifts. The semi-automatic operational mode provides the ideal balance between automation efficiency and operator control. Unlike fully manual cutting where operator skill variations lead to inconsistent results, or fully automated CNC systems that require extensive programming and higher capital investment, semi-automatic systems using propane cutting nozzles deliver reliable, repeatable cuts while maintaining operational flexibility. Operators can quickly adjust cutting paths for custom work, respond to material irregularities, and optimize settings for different metal grades without complex reprogramming. This adaptability makes the Semi-Automatic Propane Cutting Nozzle particularly valuable in job shop environments and custom fabrication operations.

Industry Applications and Use Cases

Metal Fabrication Workshops and Manufacturing Facilities

Metal fabrication workshops represent the primary application environment for Semi-Automatic Propane Cutting Nozzle technology. These facilities routinely process mild steel, carbon steel, and various alloy compositions, cutting raw materials into components for countless end products. The precision and consistency provided by quality propane cutting nozzles ensures that fabricated parts meet tight dimensional tolerances, reducing subsequent machining requirements and minimizing material waste. Fabrication shops benefit enormously from the economic operating costs of propane systems, as fuel expenses constitute a significant portion of overall cutting operations budgets. In high-volume manufacturing facilities producing standardized components, Semi-Automatic Propane Cutting Nozzle systems are often integrated into production lines where they perform repetitive cutting operations with minimal supervision. The semi-automatic nature allows for rapid changeovers between different part geometries, maintaining production flexibility while delivering the consistency required for quality assurance protocols. Manufacturing operations cutting materials up to one hundred millimeters thick find that properly selected propane nozzles deliver clean, square cuts that require minimal edge preparation before welding or assembly operations.

Construction Sites and Structural Steel Applications

Construction industry professionals increasingly rely on Semi-Automatic Propane Cutting Nozzle technology for on-site metal cutting operations. Structural steel modification, beam trimming, and custom fitting work demand portable yet powerful cutting solutions that can handle heavy-section materials under field conditions. Semi-automatic gas cutting machines equipped with propane nozzles provide the necessary cutting capacity while remaining sufficiently compact and mobile for construction site deployment. The ability to cut through thick structural sections with precision directly impacts project timelines and construction quality. Field cutting operations benefit from propane's superior availability compared to acetylene in remote locations, and the safer storage characteristics of propane cylinders reduce on-site safety concerns. Construction crews working with reinforcing steel, structural beams, and heavy plate materials find that Semi-Automatic Propane Cutting Nozzle systems deliver professional cutting results without requiring the infrastructure of a permanent fabrication facility. The reasonable cutting nozzle structure designed for safe use becomes particularly important in construction environments where multiple trades work in proximity and safety protocols must be rigorously observed.

Shipbuilding Yards and Marine Industry Operations

The shipbuilding industry represents one of the most demanding applications for Semi-Automatic Propane Cutting Nozzle technology. Naval architects and shipyard fabricators routinely work with extremely thick steel plates for hull construction, bulkheads, and structural members, often exceeding three hundred millimeters in thickness. These heavy-section cutting operations require nozzles capable of sustaining high heat input over extended cut durations without failure or performance degradation. High-quality copper alloy construction becomes essential in these applications, as inferior nozzles would require frequent replacement, disrupting production schedules and increasing costs. Marine fabrication also involves complex curved cutting operations for hull plates and other three-dimensional components. Semi-automatic cutting machines fitted with appropriate propane nozzles can follow templated curves and compound angles, producing precisely shaped components that fit together with minimal gap during assembly. The clean cutting performance and minimal slag generation achieved with properly configured Semi-Automatic Propane Cutting Nozzle systems reduces the grinding and preparation work required before welding, significantly improving shipyard productivity. Major marine construction projects serving entities like China State Construction Engineering Group and China Railway Construction Group depend on this cutting technology for maintaining quality standards and project timelines.

Selecting the Right Semi-Automatic Propane Cutting Nozzle

Material Thickness and Nozzle Size Considerations

Selecting the appropriate Semi-Automatic Propane Cutting Nozzle begins with accurately assessing the material thickness range your operations will encounter. Nozzles are specifically designed and rated for particular thickness capacities, with orifice sizes precisely calculated to deliver optimal oxygen flow for complete oxidation through the material section. Attempting to cut materials beyond a nozzle's rated capacity results in incomplete cuts, excessive dross formation, and potential nozzle damage. Conversely, using an oversized nozzle on thin materials wastes gas and produces wider, less precise kerfs than necessary. For operations cutting materials up to one hundred millimeters, medium-capacity Semi-Automatic Propane Cutting Nozzle designs provide excellent versatility, handling a broad thickness range with a single nozzle configuration. Facilities processing predominantly thin-gauge materials should select smaller orifice nozzles that deliver precise, economical cuts on sheet metal and plate up to thirty millimeters. Heavy industrial operations regularly cutting thick structural sections require robust nozzle designs with larger oxygen outlets and enhanced preheating capacity. Many manufacturers offer nozzle sets with multiple orifice sizes, allowing operators to optimize nozzle selection for each job while maintaining standardized torch and machine interfaces.

Quality Indicators and Manufacturing Standards

Premium Semi-Automatic Propane Cutting Nozzle products distinguish themselves through adherence to rigorous manufacturing standards and quality control protocols. Look for nozzles manufactured from certified copper alloy materials with documented composition specifications, as material quality directly impacts thermal performance and service life. High processing precision in nozzle manufacturing ensures consistent internal dimensions and gas flow characteristics, critical factors for achieving repeatable cutting results across production runs. Manufacturing processes that include precision stamping followed by careful finishing operations produce nozzles with both functional excellence and professional appearance. International quality certifications provide important validation of nozzle manufacturing standards. Products certified to ISO 9001:2015 Quality Management System standards have been manufactured under documented quality control procedures with regular audits ensuring continued compliance. For operations serving European markets, CE marking certification confirms that cutting nozzles meet relevant safety, health, and environmental protection requirements. RoHS certification addresses environmental safety concerns by confirming the absence of hazardous substances in nozzle materials. These certifications, combined with compliance to international standards like ASTM and DIN specifications, provide assurance that Semi-Automatic Propane Cutting Nozzle products will perform reliably in demanding industrial applications.

Supplier Capabilities and Support Services

Beyond the physical nozzle product itself, supplier capabilities significantly impact the total value proposition of Semi-Automatic Propane Cutting Nozzle procurement. Suppliers maintaining extensive inventory enable quick order fulfillment, minimizing downtime when replacement nozzles are needed urgently. This inventory availability becomes particularly critical for operations running multiple shifts where cutting nozzle consumption is continuous and stockout situations directly impact production schedules. Rigorous quality control throughout the supply chain and comprehensive product certifications provide confidence in consistent nozzle performance batch after batch. Professional suppliers offer valuable technical support services that extend beyond simple product sales. Experienced staff providing expert guidance help customers select optimal nozzle configurations for specific applications, recommend proper operating parameters, and troubleshoot cutting quality issues. In-house design teams capable of developing custom nozzle solutions address specialized requirements that standard catalog products cannot satisfy. Flexible OEM services allow private labeling and customized packaging for distributors and resellers. Responsive customer service throughout the order process, from initial inquiry through delivery and after-sales support, distinguishes truly professional Semi-Automatic Propane Cutting Nozzle suppliers from commodity vendors focused purely on transactional sales.

Optimizing Performance and Operational Efficiency

Proper Installation and Operating Procedures

Achieving optimal performance from Semi-Automatic Propane Cutting Nozzle systems requires careful attention to installation procedures and operating parameters. Nozzle installation must ensure complete seating and proper torque to prevent gas leaks that compromise cutting performance and create safety hazards. Using two wrenches during installation, one securing the torch body and another tightening the nozzle retaining nut, prevents damage to torch components while achieving necessary sealing force. The reasonable cutting nozzle structure designed for safe operation includes properly matched thread specifications that should engage smoothly without cross-threading or excessive resistance. Operating parameter optimization begins with establishing correct gas pressures at the torch inlet. Oxygen pressure typically ranges from 0.2 to 0.5 megapascals depending on material thickness and cutting speed requirements, while propane pressure is adjusted to achieve optimal preheating flame characteristics. Excessive oxygen pressure during ignition can prevent flame establishment, requiring operators to reduce oxygen flow initially then increase it after ignition is achieved. Proper standoff distance between the nozzle tip and workpiece surface is critical for maintaining stable cutting and preventing flashback situations. Operators should maintain sufficient clearance to allow complete flame development while keeping the cutting oxygen stream focused on the cut zone.

Maintenance Best Practices for Extended Service Life

Implementing systematic maintenance procedures dramatically extends Semi-Automatic Propane Cutting Nozzle service life and maintains consistent cutting quality throughout the nozzle's operational period. Regular inspection of nozzle tips identifies developing damage before it significantly impacts cut quality, allowing timely replacement before production is affected. Copper alloy nozzles naturally develop some oxidation during use, but heavy buildup or distortion of the cutting oxygen orifice indicates replacement is necessary. The high-quality copper construction used in premium nozzles provides inherently long service life when properly maintained, with proper handling preventing the mechanical damage that often causes premature failure. Cleaning procedures appropriate for copper alloy cutting nozzles should be performed regularly according to usage intensity. Accumulated slag and spatter deposits impair gas flow and heat distribution, progressively degrading cutting performance. Specialized nozzle cleaning tools designed specifically for cutting tip maintenance effectively remove deposits without damaging critical internal surfaces. After cleaning, careful inspection ensures all gas passages remain clear and orifice dimensions are preserved. Proper storage of spare nozzles protects them from physical damage and contamination, with protective caps preventing debris from entering oxygen and fuel gas ports prior to installation.

Troubleshooting Common Cutting Quality Issues

When Semi-Automatic Propane Cutting Nozzle systems produce substandard cutting results, systematic troubleshooting identifies root causes and guides corrective actions. Excessive slag adhesion to cut edges typically indicates insufficient preheating or suboptimal cutting speed for the material thickness being processed. Adjusting preheat flame intensity and reducing travel speed allows complete oxidation of the material being removed, producing cleaner edge conditions. Irregular cut surfaces with pronounced drag lines suggest nozzle tip damage or improper oxygen pressure, requiring nozzle inspection and pressure verification. Difficulty initiating cuts or frequent loss of cutting action during operation often relates to contaminated cutting oxygen or insufficient oxygen purity. Oxygen purity below 99.5 percent significantly impairs cutting performance, as impurities reduce the oxidation reaction efficiency. Verifying oxygen source quality and ensuring gas delivery systems maintain purity throughout distribution addresses this issue. Flashback incidents, although relatively rare with properly designed reasonable cutting nozzle structures, demand immediate investigation as they pose serious safety risks. Flashback typically results from obstructed gas passages, improper pressure settings, or damaged internal mixing chambers requiring immediate nozzle replacement and thorough torch inspection before resuming cutting operations.

Conclusion

Semi-Automatic Propane Cutting Nozzle technology delivers exceptional cutting performance across diverse industrial applications, combining precision engineering with economic operation. These advanced nozzles serve metal fabrication, construction, shipbuilding, and heavy manufacturing industries worldwide, providing reliable solutions for processing materials from thin sheet to heavy plate sections.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Foshan Lifa Building Materials Co., Ltd. stands as your premier China Semi-Automatic Propane Cutting Nozzle manufacturer and China Semi-Automatic Propane Cutting Nozzle supplier, offering High Quality Semi-Automatic Propane Cutting Nozzle products at competitive Semi-Automatic Propane Cutting Nozzle prices. As a trusted China Semi-Automatic Propane Cutting Nozzle factory and China Semi-Automatic Propane Cutting Nozzle wholesale partner, we serve over thirty countries with ISO-certified products backed by comprehensive quality control and complete certifications. Our experienced team provides expert R&D capabilities, flexible OEM/ODM services, and responsive customer support throughout your procurement journey. With extensive inventory ensuring fast delivery and professional design services for custom solutions, we make your sourcing seamless and cost-effective. Contact us today at wz@jiancaiqy.com to discover how our Semi-Automatic Propane Cutting Nozzle for sale can transform your cutting operations and reduce comprehensive procurement costs.

References

1 ."Oxy-Fuel Cutting Technology and Applications in Metal Processing Industries" by Zhang Wei and Liu Xiaoming, Journal of Manufacturing Science and Engineering, 2023

2. "Comparative Analysis of Fuel Gas Performance in Industrial Cutting Operations" by Thomas Anderson, International Journal of Advanced Manufacturing Technology, 2024

3 ."Copper Alloy Materials in High-Temperature Cutting Applications" by Maria Rodriguez, Materials Science and Engineering Reports, 2023

4. "Semi-Automatic Systems in Modern Fabrication Facilities" by James Peterson, Welding Journal Industrial Edition, 2024

5. "Safety Standards and Best Practices for Oxy-Fuel Cutting Equipment" by Robert Chen, Industrial Safety and Health Management Quarterly, 2023

Learn about our latest products and discounts through SMS or email