- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the best wet and dry sandpaper?

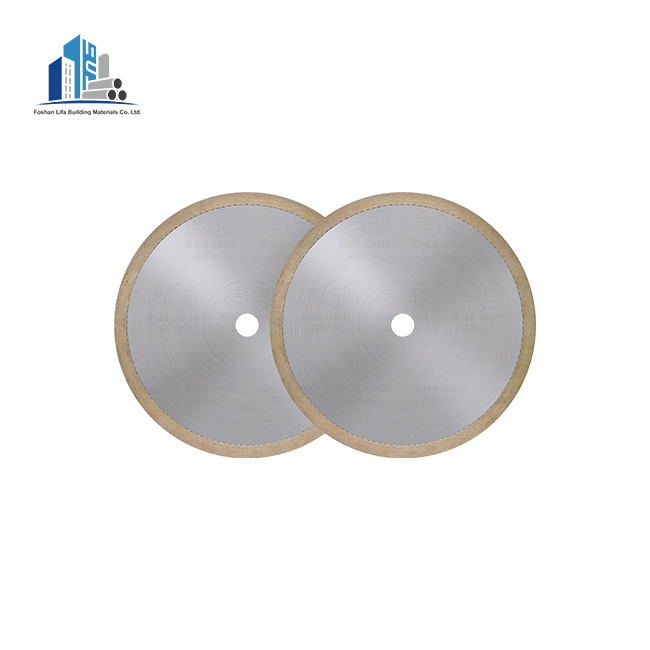

Finding the right wet and dry sandpaper can be the difference between a professional-grade finish and a frustrating project failure. Whether you're dealing with automotive bodywork, woodworking projects, or industrial applications, choosing the wrong abrasive can lead to surface damage, wasted materials, and endless rework. The best wet and dry sandpaper combines superior silicon carbide abrasive grains with waterproof backing, offering exceptional durability and versatility for both wet and dry applications. Round wet and dry sandpaper, in particular, provides optimal performance for disc sanders and orbital tools, delivering consistent results across various materials and surface conditions.

Understanding Round Wet and Dry Sandpaper Technology

Round wet and dry sandpaper represents a significant advancement in abrasive technology, designed specifically to meet the demanding requirements of professional and industrial applications. Unlike traditional sandpaper that can only function effectively in dry conditions, these specialized abrasives feature waterproof backing materials that maintain their structural integrity when exposed to moisture or liquid lubricants. The construction of high-quality round wet and dry sandpaper typically involves silicon carbide abrasive grains that are precisely bonded to latex paper or cloth backing using advanced resin systems. This construction method ensures that the abrasive particles remain securely attached to the backing material, even under the challenging conditions of wet sanding operations. The silicon carbide grains are particularly effective because they feature a friable characteristic, meaning they self-sharpen during use, continuously exposing fresh cutting edges that maintain consistent abrasive performance throughout the product's lifespan.

-

Key Features of Premium Round Wet and Dry Sandpaper

Premium round wet and dry sandpaper incorporates several critical features that distinguish it from standard abrasive products. Water-resistant properties ensure that the backing material does not deteriorate when exposed to moisture, while good wear resistance extends the operational life of each disc. Fine workmanship in the manufacturing process guarantees uniform grain distribution and consistent thickness, which translates to smooth, even surface finishes. High strength construction prevents premature tearing or delamination during aggressive sanding operations, while the specially formulated backing resists curling even under high-temperature conditions. Smooth and glossy processing capabilities allow for achieving mirror-like finishes on various materials, with less heat generation during grinding operations compared to conventional abrasives. The tear-resistant design ensures reliable performance in demanding industrial environments, delivering consistently good results across diverse applications.

Material Composition and Grit Selection for Round Wet and Dry Sandpaper

The material composition of round wet and dry sandpaper plays a crucial role in determining its performance characteristics and suitability for specific applications. Silicon carbide remains the preferred abrasive grain for wet sanding applications due to its sharp cutting action and excellent performance on hard materials such as metals, plastics, and painted surfaces. Aluminum oxide variants are also available for applications requiring different cutting characteristics, particularly when working with softer materials or when longer product life is prioritized. Grit selection ranges typically span from coarse 60-grit options for heavy material removal to ultra-fine 3000-grit variants for final polishing operations. The extensive grit range available in round wet and dry sandpaper allows users to accomplish complete surface preparation and finishing processes using products from a single manufacturer, ensuring consistency in quality and performance throughout multi-stage operations.

-

Diameter Options and Backing Materials

Round wet and dry sandpaper is commonly available in 5-inch and 6-inch diameters, with custom sizes available to meet specific equipment requirements. The standardized diameters ensure compatibility with common power sanding equipment, while custom sizing options accommodate specialized machinery and unique application requirements. Backing materials include latex paper for general-purpose applications and cloth backing for heavy-duty operations requiring maximum durability. The latex paper backing provides adequate strength for most applications while maintaining flexibility for contoured surfaces, whereas cloth backing offers superior tear resistance for aggressive material removal operations and extended use cycles.

Industrial Applications of Round Wet and Dry Sandpaper

The versatility of round wet and dry sandpaper makes it indispensable across numerous industrial sectors. In automotive applications, these abrasives excel in paint preparation and body work, where the ability to switch between wet and dry sanding without changing products significantly improves workflow efficiency. The waterproof construction allows for wet sanding operations that minimize dust generation while achieving superior surface finishes required for high-quality paint adhesion. Metalworking industries rely on round wet and dry sandpaper for surface finishing and polishing operations, where the silicon carbide grains effectively remove oxidation, scale, and surface imperfections while preparing surfaces for subsequent coating or treatment processes. The consistent performance characteristics ensure predictable results in production environments where quality control is paramount.

-

Specialized Sector Applications

Woodworking applications benefit from the smooth finishing capabilities of round wet and dry sandpaper, particularly for between-coat sanding where the waterproof backing allows for use with various sanding lubricants and finishing compounds. The consistent scratch pattern achieved with quality round wet and dry sandpaper ensures uniform stain and finish penetration across wooden surfaces. Electronics manufacturing utilizes fine-grit round wet and dry sandpaper for PCB preparation and component finishing, where precision and contamination control are critical requirements. The ability to use these abrasives with cleaning solvents or other specialized liquids makes them ideal for applications requiring both mechanical abrasion and chemical cleaning processes. Marine industry applications include hull maintenance and deck restoration, where the waterproof nature of round wet and dry sandpaper allows for use in inherently wet environments without compromising performance. The corrosion-resistant backing materials withstand exposure to saltwater and marine chemicals while maintaining their abrasive effectiveness. Aerospace applications demand the highest levels of precision and quality, making premium round wet and dry sandpaper essential for precision surface preparation operations. The consistent performance and reliability required in aerospace manufacturing makes quality round wet and dry sandpaper a critical component in maintaining the stringent standards required for aircraft components.

Quality Standards and Manufacturing Excellence

The manufacturing of premium round wet and dry sandpaper requires adherence to strict quality control standards and international certifications. ISO 9001:2015 Quality Management System certification ensures that manufacturing processes consistently produce products meeting specified requirements, while rigorous quality control measures guarantee that every batch meets performance standards. Advanced manufacturing facilities employ state-of-the-art technology and experienced technical teams to ensure optimal product consistency and performance. The manufacturing process involves precise control of abrasive grain distribution, resin application, and backing material properties to achieve the superior performance characteristics expected from professional-grade round wet and dry sandpaper.

-

Certification and Compliance

International quality standards including CE Certification and RoHS Compliance demonstrate commitment to both product quality and environmental responsibility. These certifications provide assurance that round wet and dry sandpaper products meet the safety and environmental requirements for use in international markets. The comprehensive testing protocols employed during manufacturing include adhesion strength testing, waterproof integrity verification, and abrasive performance validation under controlled conditions. These testing procedures ensure that every batch of round wet and dry sandpaper meets or exceeds performance specifications before reaching end users.

Conclusion

Selecting the best wet and dry sandpaper requires careful consideration of material composition, grit selection, and backing materials to match specific application requirements. Round wet and dry sandpaper offers superior versatility and performance for professional and industrial applications, combining waterproof construction with consistent abrasive action. Quality manufacturing and adherence to international standards ensure reliable performance across diverse applications, making premium round wet and dry sandpaper an essential tool for achieving professional-grade surface finishing results.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

As a leading China Round wet and dry sandpaper factory, Foshan Lifa Building Materials Co., Ltd. stands as your trusted China Round wet and dry sandpaper supplier and China Round wet and dry sandpaper manufacturer. We offer comprehensive China Round wet and dry sandpaper wholesale solutions with competitive Round wet and dry sandpaper prices for our High Quality Round wet and dry sandpaper products. Our extensive inventory ensures Round wet and dry sandpaper for sale availability when you need it most. Partner with our experienced team for OEM/ODM customization, rapid delivery, and exceptional customer service. Contact us at wz@jiancaiqy.com for your Round wet and dry sandpaper requirements and discover why professionals worldwide choose our solutions.

FAQ

Q: What grit range is available for round wet and dry sandpaper?

A: Round wet and dry sandpaper is typically available in grits ranging from 60 for heavy material removal to 3000 for ultra-fine polishing applications.

Q: Can round wet and dry sandpaper be used with power sanders?

A: Yes, round wet and dry sandpaper is specifically designed for use with orbital sanders, disc sanders, and other power sanding equipment in both wet and dry applications.

Q: What backing materials are used in round wet and dry sandpaper?

A: Common backing materials include latex paper for general applications and cloth backing for heavy-duty operations requiring maximum durability and tear resistance.

Q: What industries commonly use round wet and dry sandpaper?

A: Primary industries include automotive, metalworking, woodworking, electronics, marine, and aerospace sectors where versatile wet and dry sanding capabilities are essential.

References

1. "Abrasive Technology and Applications in Manufacturing Industries" - Industrial Abrasives Research Institute, Manufacturing Engineering Department

2. "Surface Preparation Techniques for Industrial Coatings" - National Association of Corrosion Engineers, Technical Publications Division

3. "Quality Control Standards for Abrasive Products" - International Organization for Standardization, Technical Committee on Abrasives

4. "Advanced Materials in Abrasive Manufacturing" - Society of Manufacturing Engineers, Materials and Processing Technology Section

Learn about our latest products and discounts through SMS or email