- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Every Technician Needs a Hand Tube Bender Manual Guide?

Imagine standing at a critical installation point, tube in hand, only to realize your bend angles are inconsistent, your measurements are off, and you're wasting valuable materials with each failed attempt. This frustrating scenario plays out daily for technicians who underestimate the importance of proper tube bending guidance. A comprehensive hand tube bender manual serves as your essential companion, transforming guesswork into precision and preventing costly errors that can derail entire projects.

Understanding the Critical Role of Hand Tube Bender Manual Documentation

Professional technicians across industries face mounting pressure to deliver flawless installations with minimal material waste and maximum efficiency. The hand tube bender manual represents far more than a simple instruction booklet—it functions as a technical reference guide that addresses the complex physics of metal forming, springback compensation, and precision measurement techniques. Without proper documentation, even experienced professionals struggle with gain calculations, offset bend formulas, and angle adjustments that separate amateur work from professional results. The complexity of modern tube bending operations demands systematic approaches that only well-structured hand tube bender manual guides can provide. These comprehensive resources cover everything from basic tube preparation protocols to advanced troubleshooting scenarios that arise during challenging installations. When working with materials like high-strength alloy steel or specialized stainless steel tubing, the margin for error shrinks dramatically, making proper manual consultation not just helpful but absolutely essential for maintaining professional standards and avoiding expensive material waste.

Essential Technical Information Every Manual Should Provide

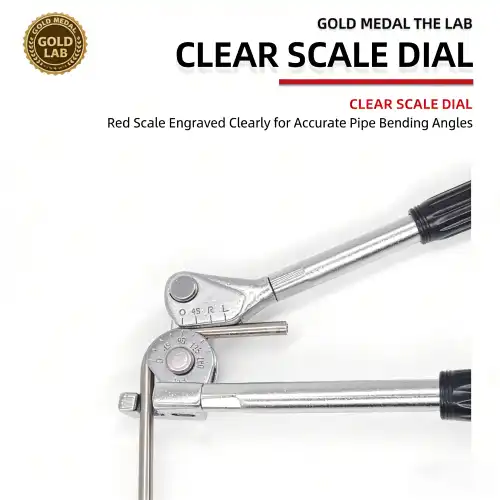

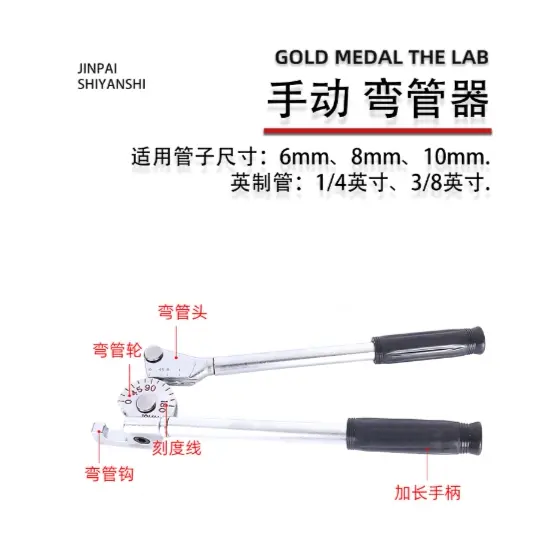

A quality hand tube bender manual must include detailed specifications about tube capacity ranges, typically covering diameters from one-quarter inch to one inch outside diameter. Professional-grade tools manufactured from thickened ductile iron offer extended service life, but operators need clear guidance on material limitations and hardness ratings to prevent equipment damage. The manual should explain how surface treatments, such as fine baking paint resistant to acid, alkali, and oil, protect the tool while maintaining measurement accuracy over thousands of bending cycles. Technical documentation must address the simple yet effective design features that prevent pipe breakage caused by excessive force application. Understanding leverage points, proper handle positioning, and force distribution helps technicians work more efficiently while extending both tool life and material quality. Comprehensive hand tube bender manual guides explain how bend angles up to one hundred eighty degrees require different techniques, with specific attention to springback phenomena that varies based on material properties, tube wall thickness, and ambient temperature conditions during the bending operation.

Precision Measurement Techniques and Gain Calculations

Mastering precision bending requires deep understanding of gain calculations—the mathematical adjustments necessary to compensate for the difference between theoretical straight-line measurements and the actual curved path through radiused bends. Without proper hand tube bender manual reference materials, technicians often struggle with these critical calculations, resulting in tubes that come up short or extend too far for proper installation. Professional manuals provide detailed tables showing fractional adjustments based on bend angles and outside tube diameters, eliminating time-consuming trial-and-error approaches that waste both materials and project timelines. The most effective hand tube bender manual resources include step-by-step measurement protocols that ensure consistent results across multiple bending operations. These procedures cover proper marking techniques, vertex identification, and reference point alignment that form the foundation of accurate tube bending. When working on complex projects requiring multiple bends in different planes, having reliable documentation prevents cumulative errors that compound throughout the installation process. Professional technicians understand that fifteen minutes spent consulting their manual can save hours of rework and hundreds of dollars in wasted materials.

Practical Applications Across Multiple Industries

HVAC System Installations and Maintenance

HVAC professionals rely heavily on precise tube bending capabilities when installing refrigerant lines, condensate drains, and complex ductwork connections. The hand tube bender manual becomes an indispensable reference when working in confined spaces where pre-fabricated components won't fit and custom bending becomes necessary. Technicians working with copper refrigerant lines must maintain specific bend radiuses to prevent flow restrictions that reduce system efficiency and potentially void manufacturer warranties. Detailed manual guidance helps ensure compliance with industry standards while maintaining the structural integrity essential for pressure-bearing applications. Climate control installations often require offset bends and reverse bends that challenge even experienced technicians without proper documentation. A comprehensive hand tube bender manual explains how to plan complex routing paths, calculate multiple bend sequences, and maintain consistent quality throughout large-scale installations. When working on commercial HVAC projects for major clients like China State Construction Engineering Group, the difference between amateur and professional results often comes down to proper manual consultation and technique implementation that only thorough documentation can provide.

Automotive Brake Line Repairs and Custom Fabrication

Automotive technicians face unique challenges when repairing or fabricating brake lines, where safety concerns make precision absolutely non-negotiable. The hand tube bender manual provides critical guidance on material selection, bend radius requirements, and installation procedures that meet stringent automotive safety standards. Working with steel brake tubing requires different approaches than copper or aluminum applications, with specific attention to springback compensation and proper flaring techniques that ensure leak-free connections capable of withstanding high hydraulic pressures. Custom automotive fabrication projects demand even more extensive hand tube bender manual consultation, particularly when creating unique fuel lines, oil cooler connections, or performance modifications. Professional fabricators understand that poorly executed bends can create stress concentration points that fail under vibration and thermal cycling common in automotive environments. Quality manuals address these concerns with detailed troubleshooting sections that help identify potential problems before they become safety hazards, protecting both technicians and end users from preventable failures.

Selecting Quality Tools with Proper Documentation Support

Material Construction and Durability Considerations

Professional-grade hand tube bender tools manufactured from thickened ductile iron demonstrate superior longevity compared to lighter-weight alternatives, but only when operators understand proper usage techniques outlined in comprehensive manuals. The forged construction provides necessary strength for repeated bending operations without deformation or accuracy degradation. Quality manufacturers like Foshan Lifa Building Materials Co., Ltd. recognize that superior materials mean little without proper documentation explaining maintenance schedules, lubrication requirements, and storage protocols that preserve tool accuracy over extended service periods. Surface protection features, including fine baking paint resistant to harsh chemicals, maintain measurement accuracy by preventing corrosion that can alter critical dimensions. The hand tube bender manual should explain how environmental factors affect tool performance and what maintenance steps preserve these protective coatings. Understanding these details helps technicians make informed purchasing decisions and implement proper care routines that maximize their investment value while ensuring consistent bending accuracy throughout the tool's operational lifetime.

Technical Specifications That Matter for Professional Work

When evaluating hand tube bender options, technicians must consider specifications like tube capacity ranges, maximum bend angles, and overall tool dimensions that affect portability and workspace requirements. A tool handling tubes from one-quarter inch to one inch outside diameter with capabilities up to one hundred eighty-degree bends serves most professional applications, but the hand tube bender manual must clearly explain operational limits and appropriate use cases. Tools weighing approximately five and a half pounds offer good portability while maintaining necessary structural rigidity for accurate bending operations. Physical dimensions around eighteen inches by six inches by four inches provide compact storage while delivering adequate leverage for professional bending applications. However, the hand tube bender manual becomes crucial when technicians need to understand how dimensional specifications translate to practical workspace requirements and leverage capabilities. Detailed documentation helps users match tool capabilities to specific project demands, avoiding situations where inadequate equipment compromises installation quality or where oversized tools create unnecessary handling difficulties in confined work environments.

Comprehensive Training and Skill Development Resources

Effective hand tube bender manual resources function as ongoing training tools that support skill development from novice to expert levels. Initial sections cover fundamental concepts like tube preparation, proper clamping techniques, and basic single-bend operations that build foundational competencies. As technicians gain experience, advanced sections addressing reverse bends, offset calculations, and multi-plane bending sequences provide pathways for professional growth. This progressive approach ensures that one quality manual serves throughout an entire career, adapting to expanding skill sets and increasingly complex project requirements. Professional development demands regular consultation with hand tube bender manual resources, even for experienced technicians tackling unfamiliar materials or unusual bending scenarios. The most valuable manuals include extensive troubleshooting sections that address common problems like flattening, kinking, or inconsistent bend angles. These diagnostic resources help technicians identify root causes quickly, implementing corrective measures that restore quality without extensive trial-and-error experimentation. Organizations serving major contractors like China Railway Construction Group understand that consistent manual consultation separates reliable performers from technicians who struggle with complex installations.

Conclusion

Every professional technician requires reliable hand tube bender manual guidance to achieve consistent precision, minimize material waste, and deliver installations meeting rigorous industry standards across HVAC, automotive, plumbing, and industrial applications.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Partner with Foshan Lifa Building Materials Co., Ltd., your trusted China hand tube bender manual factory and China hand tube bender manual supplier offering high quality hand tube bender manual tools at competitive hand tube bender manual prices. As a leading China hand tube bender manual manufacturer providing hand tube bender manual wholesale and hand tube bender manual for sale, we combine over a decade of manufacturing excellence with comprehensive OEM support, strict quality certifications including ISO9001, ASTM, and DIN compliance, and experienced staff delivering exceptional service across thirty-plus countries. Our professional design team, rigorous quality control, extensive inventory, and competitive cost advantages make us the preferred China hand tube bender manual supplier for international distributors, contractors, and major clients. Contact our expert team at wz@jiancaiqy.com today to discuss your specific requirements, request detailed product specifications, or explore custom OEM solutions tailored to your market needs. Save this resource for future reference and reach out whenever your projects demand reliable, precision-engineered tube bending solutions backed by comprehensive technical support.

References

1. "Hand Tube Bender Manual: Technical Guide for Precision Tube Bending," Swagelok Company, Industrial Fluid Systems Division

2. "Manual Tube Bending: Principles and Practices for Professional Applications," FITOK Group, Engineering Documentation Series

3. "Tube Bending Techniques and Gain Calculations for HVAC Applications," American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), Technical Manual

4. "Automotive Brake Line Installation and Fabrication Standards," Society of Automotive Engineers (SAE), Professional Guidelines Series

5. "Industrial Tube Bending Equipment: Selection and Operation Manual," International Association of Plumbing and Mechanical Officials (IAPMO), Technical Standards Divisio

Learn about our latest products and discounts through SMS or email