- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Benefits of Using an Electric Grouting Machine in Civil Works

Cracked foundations, water leakage, and structural instability—these are common nightmares in civil construction projects that can escalate costs and delay timelines. Modern civil works demand efficient, reliable solutions for sealing voids, strengthening foundations, and preventing water ingress. An electric grouting machine offers the precision, power, and consistency needed to address these critical challenges, transforming how contractors approach repair and reinforcement work while ensuring superior results in tunnels, dams, bridges, and underground structures.

Enhanced Efficiency and Productivity with Electric Grouting Machines

Modern civil construction demands equipment that maximizes productivity without compromising quality. The electric grouting machine revolutionizes traditional grouting methods by delivering consistent, high-pressure injection that dramatically reduces project timelines. Unlike manual grouting methods that rely on labor-intensive processes and unpredictable results, electric grouting machines provide automated control over pressure, flow rate, and material distribution. These machines can inject grouting materials continuously at pressures reaching 18,000 PSI, enabling workers to cover larger surface areas in significantly less time. The automated nature of electric grouting machines means that a single operator can accomplish what previously required multiple workers, reducing labor costs while maintaining superior quality standards. In large-scale infrastructure projects such as tunnel construction, dam reinforcement, and subway systems, the time saved translates directly into substantial cost savings and faster project completion. The precision injection capabilities of electric grouting machines ensure that every crack, void, and cavity receives the exact amount of material needed for optimal sealing. Advanced pressure gauges and flow control mechanisms built into these machines allow operators to adjust settings based on specific project requirements, whether working with low-viscosity polyurethane or high-strength epoxy resins. This level of control eliminates material waste, ensures consistent application throughout the project, and significantly improves the structural integrity of treated areas. For contractors working on critical infrastructure where downtime must be minimized, the electric grouting machine provides the speed and reliability necessary to meet tight deadlines without sacrificing quality.

Versatile Application Across Multiple Civil Engineering Projects

The electric grouting machine demonstrates remarkable versatility across diverse civil engineering applications, making it an indispensable tool for modern construction projects. In foundation reinforcement work, these machines inject stabilizing materials deep into soil formations to improve load-bearing capacity and prevent settlement issues that could compromise structural integrity. Underground construction projects, including subway tunnels, culverts, and sewage systems, benefit from the machine's ability to seal joints, prevent water ingress, and fill voids between rock faces and tunnel linings. Dam construction and maintenance operations rely heavily on electric grouting machines for creating impermeable barriers, treating water seepage, and consolidating core materials to ensure long-term structural stability. Bridge repair and rehabilitation projects utilize electric grouting machines to address expansion joints, seal cracks in concrete piers and abutments, and strengthen aging infrastructure without requiring extensive demolition or reconstruction. The machines excel at injecting materials into confined spaces and hard-to-reach areas, making them ideal for repairing deteriorated structures while minimizing disruption to traffic and surrounding areas. Soil stabilization projects employ electric grouting machines to inject chemical or cement-based grouts into loose or unstable ground conditions, improving bearing capacity and preventing erosion. The ability to work with various grouting materials—including water-soluble polyurethane, oil-soluble polyurethane, epoxy resins, and acrylic esters—ensures that contractors can select the optimal solution for specific soil conditions, environmental factors, and performance requirements.

Superior Material Compatibility and High-Pressure Performance

The electric grouting machine distinguishes itself through exceptional compatibility with diverse grouting materials and the ability to maintain high-pressure performance throughout extended operations. These machines feature stainless steel alloy pump cores that provide superior corrosion resistance, wear resistance, and precision sealing capabilities essential for handling both water-based and chemical grouting compounds. The ABS plastic barrels offer anti-corrosion properties and durability that withstand the harsh chemicals commonly used in construction applications, from polyurethane plugs to epoxy resins and acrylic esters. When operating at maximum pressures of 50 MPa, quality electric grouting machines maintain structural integrity without deformation, ensuring consistent performance even under the most demanding conditions. The high-pressure capabilities of electric grouting machines enable effective penetration into fine cracks, micropores, and tight spaces that conventional methods cannot reach. This is particularly critical when treating water-damaged concrete structures, where thorough material infiltration determines the success of waterproofing and structural reinforcement efforts. The machines' ability to maintain steady pressure throughout the injection process ensures complete void filling and eliminates air pockets that could compromise the integrity of the repair. For projects involving low-viscosity liquid materials, the electric grouting machine provides the precise control needed to achieve proper material distribution without over-pressurization that could damage existing structures.

Cost-Effectiveness and Long-Term Value

Investing in an electric grouting machine delivers substantial long-term financial benefits that extend far beyond the initial purchase price. The reduction in labor requirements alone generates significant savings, as a single skilled operator can accomplish grouting tasks that traditionally required multiple workers. Material efficiency represents another major cost advantage—the precise control systems built into electric grouting machines minimize waste by delivering exactly the right amount of grout to each injection point. This precision eliminates the overuse common with manual methods, where excess material often goes to waste due to imprecise application. Over the course of major infrastructure projects, these material savings can amount to thousands or even tens of thousands of dollars. The durability and low maintenance requirements of quality electric grouting machines further enhance their cost-effectiveness. Machines featuring wear-resistant alloy pumps and corrosion-resistant components can operate reliably for years with minimal downtime when properly maintained. Simple maintenance procedures—such as flushing the system with appropriate solvents after use—preserve component integrity and prevent costly repairs or premature equipment replacement. The extended service life of electric grouting machines ensures that contractors can amortize their investment across numerous projects, improving overall return on investment. Additionally, the superior quality of work produced by electric grouting machines reduces the likelihood of repair failures, callbacks, and warranty claims that can erode profit margins and damage professional reputations.

Improved Safety and Structural Protection

Safety considerations in civil construction extend to both worker protection and structural preservation, areas where electric grouting machines excel. The non-destructive nature of electric grouting injection eliminates the need for extensive excavation, groove cutting, or pipe burial that traditional methods require. This approach preserves the integrity of existing structures while addressing underlying problems, reducing the risk of unintended damage during repair operations. The machines' compact size and lightweight design enhance portability and ease of operation in confined spaces, reducing physical strain on workers and minimizing accident risks associated with maneuvering heavy equipment in challenging environments. The controlled injection process provided by electric grouting machines significantly reduces exposure to hazardous materials and high-pressure fluids. Operators can maintain safe distances from injection points while monitoring pressure gauges and flow indicators, minimizing direct contact with potentially harmful chemicals. The precision delivery system prevents material spillage and reduces airborne particulate exposure that can occur with manual mixing and application methods. For underground construction projects, the ability to seal water leaks and stabilize ground conditions without disturbing adjacent structures protects both workers and nearby infrastructure from collapse risks, flooding hazards, and other safety concerns. The electric grouting machine's rapid deployment capabilities enable quick response to emergency situations such as unexpected water ingress or structural instability, preventing minor issues from escalating into major safety incidents.

Technical Specifications and Performance Standards

Understanding the technical capabilities of electric grouting machines helps contractors select equipment that matches project requirements. High-performance models typically feature adjustable power supplies accommodating both 110V and 220V at 50Hz, ensuring compatibility with various job site electrical configurations. Motor power ratings ranging from 1100W to 4000W provide the driving force necessary for consistent material injection, with variable speed controls from 0 to 2800 RPM allowing operators to adjust performance based on material viscosity and application requirements. Flow rates of 0.74 to 60 liters per minute enable efficient material delivery whether treating small cracks or large voids requiring substantial grout volumes. Pressure capabilities represent critical performance parameters, with quality electric grouting machines delivering maximum output pressures between 6 MPa and 18,000 PSI. This range accommodates everything from low-pressure applications in sensitive structures to high-pressure injection requirements for dense concrete or rock formations. High-pressure hose systems rated for 10,000 to 15,000 PSI safety ranges ensure reliable material delivery without hose failure risks. Upgraded metal skin hoses offer superior strength compared to traditional plastic hoses, withstanding maximum pressures without rupture or deformation. Switch valves with safety ranges up to 18,000 PSI and restart pressures around 7,500 PSI provide precise control over injection cycles and prevent dangerous over-pressurization scenarios.

Practical Operational Considerations

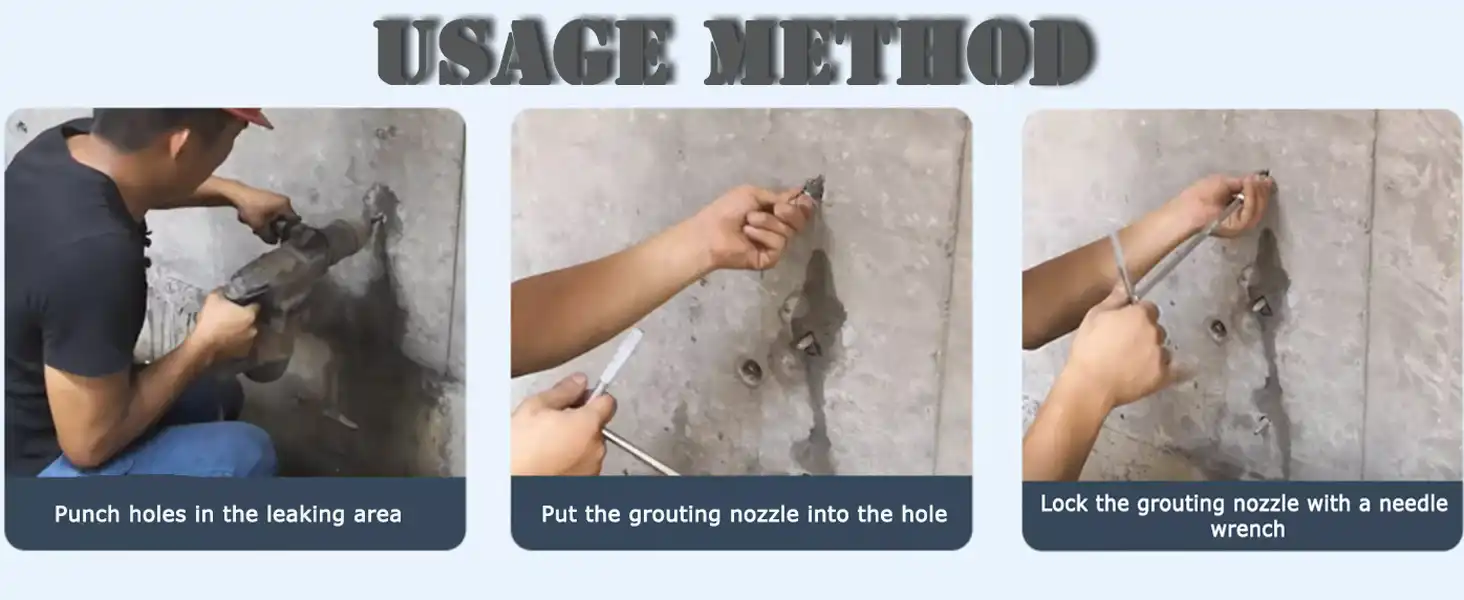

Successful operation of electric grouting machines requires understanding proper preparation, material selection, and maintenance procedures. Before beginning grouting operations, contractors must clean target surfaces thoroughly using high-pressure water jets or appropriate surface preparation techniques to ensure optimal material adhesion. Pre-soaking concrete surfaces creates saturated surface dry conditions that enhance grout penetration and bonding. Material selection depends on specific application requirements—water-soluble polyurethane caulking agents work effectively for dynamic cracks subject to movement, while oil-soluble polyurethane plugs provide excellent performance in wet conditions with active water flow. Epoxy resins deliver high structural strength for load-bearing applications, and acrylic esters offer rapid curing for emergency repairs requiring quick turnaround times. Operators must carefully manage material working times to prevent premature hardening within the electric grouting machine. Most polyurethane and epoxy formulations have working times ranging from 8 to 20 minutes depending on temperature and chemical composition. Regular flushing of the pump system with appropriate solvents—such as acetone, xylene, or specialized thinners—immediately after material injection prevents material jamming in channels and hoses that could require extensive cleaning or component replacement. Testing machines before first use with vegetable oil rather than water protects against component damage while verifying proper operation. Understanding that grouting fluids cannot contain solid particles such as cement mortar prevents pump damage and ensures consistent flow characteristics throughout injection operations.

Quality Assurance and Project Success

The electric grouting machine plays a crucial role in maintaining quality standards throughout civil engineering projects. Advanced monitoring systems built into modern machines track pressure, flow rates, and material volumes in real-time, providing verifiable data for quality control documentation and project records. This level of monitoring enables immediate detection of anomalies such as pressure drops indicating crack propagation, flow interruptions suggesting blockages, or excessive material consumption revealing unexpected voids. By addressing these issues immediately rather than discovering them during post-project inspections, contractors prevent costly rework and ensure first-time quality that meets or exceeds specification requirements. The consistency delivered by electric grouting machines eliminates the variability inherent in manual grouting methods, where different operators may apply materials with varying pressures, coverage rates, and injection techniques. This standardization proves particularly valuable on large projects involving multiple work crews or extended timelines where maintaining uniform quality throughout all phases can be challenging. For projects requiring third-party inspections or strict regulatory compliance, the documentation capabilities of electric grouting machines provide the verification needed to demonstrate adherence to specifications. The machines' ability to achieve complete void filling and thorough crack penetration ensures structural repairs perform as designed, extending service life and reducing the likelihood of premature failure requiring additional remediation efforts.

Conclusion

Electric grouting machines transform civil construction by combining efficiency, precision, and versatility, delivering superior structural reinforcement while reducing costs and project timelines across infrastructure applications.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Partner with Foshan Lifa Building Materials Co., Ltd., your trusted China electric grouting machine manufacturer, offering premium-quality solutions as a leading China electric grouting machine supplier and China electric grouting machine factory. Our China electric grouting machine wholesale program provides competitive electric grouting machine prices on high quality electric grouting machines for sale, backed by ISO9001, ASTM, and DIN certifications. With extensive inventory ensuring immediate shipment, rigorous quality control, flexible OEM support, and an in-house design team, we serve over 30 countries including major contractors like China State Construction Engineering Group. Our experienced staff provides expert guidance throughout your procurement process, delivering exceptional value and professional communication. Save this page for quick reference, and contact us today at wz@jiancaiqy.com to discuss your electric grouting machine requirements and receive a customized quotation that meets your project specifications.

References

1. American Concrete Institute. "Guide to Grouting of Cracks in Concrete." ACI Committee 224, Technical Report.

2. International Tunnelling and Underground Space Association. "Guidelines for Grouting in Tunnelling." Working Group on Grouting and Ground Treatment.

3. British Standards Institution. "Code of Practice for Grouting." BS EN 12715, Execution of Special Geotechnical Works.

4. U.S. Army Corps of Engineers. "Grouting Technology for Dam Foundations." Engineering Manual EM 1110-2-3506.

5. Canadian Geotechnical Society. "Grouting Methods and Applications in Ground Improvement." Canadian Foundation Engineering Manual, Fourth Edition.

Learn about our latest products and discounts through SMS or email