- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Concrete Slotting Machine Uses in Construction and Utilities?

Every construction professional knows the frustration of manually chiseling channels through concrete walls for electrical conduits or plumbing installations. Hours of labor-intensive work, dust clouds filling the workspace, and inconsistent groove depths that compromise installation quality. The concrete slotting machine revolutionizes this process by delivering precise, clean cuts through tough materials in minutes rather than hours. This powerful tool transforms how contractors approach wall chasing, utility installations, and concrete surface modifications across construction and utility sectors.

Understanding the Concrete Slotting Machine and Its Core Functions

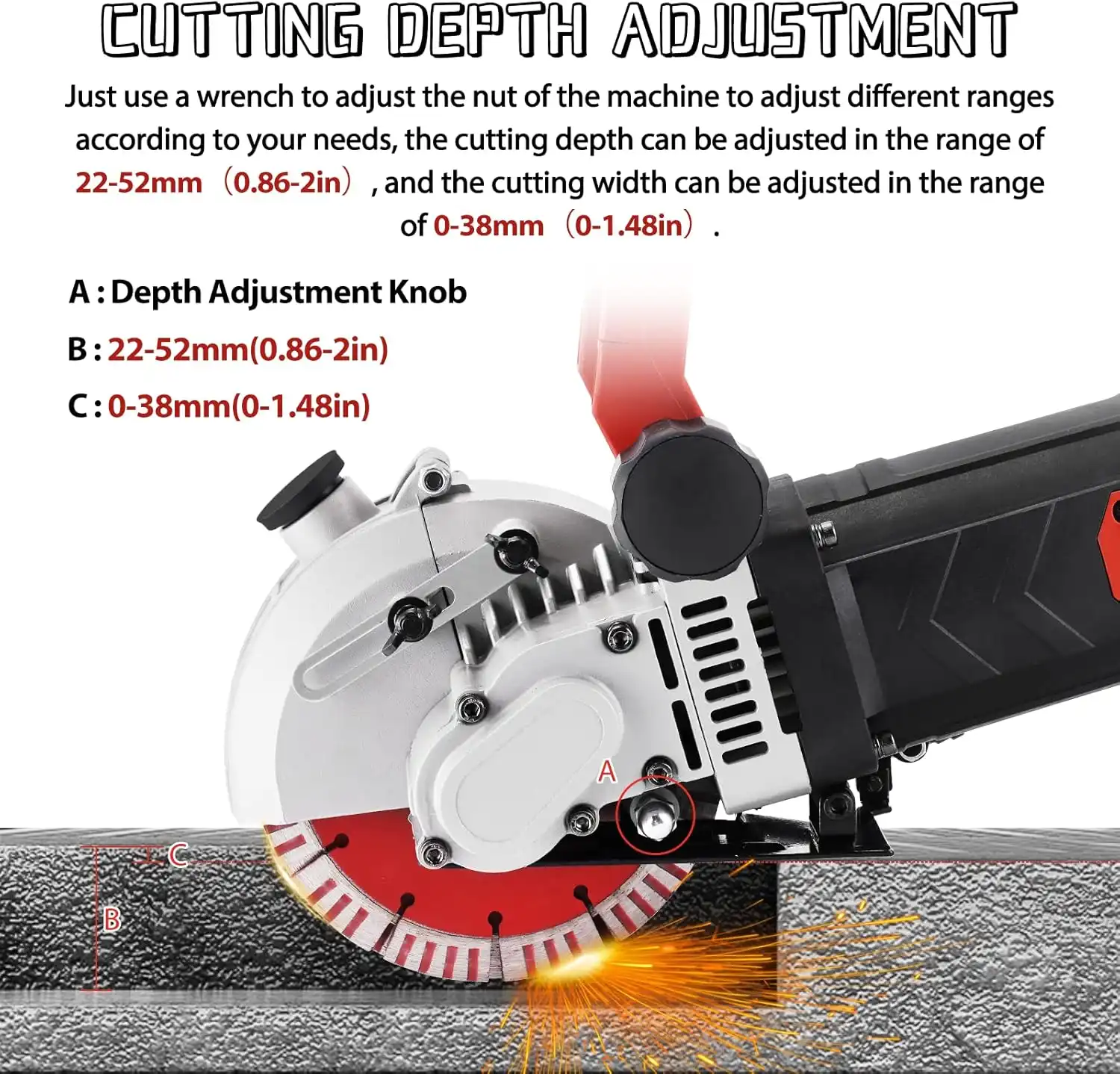

The concrete slotting machine represents a specialized power tool engineered specifically for creating precise channels and grooves in concrete, masonry, and other hard construction materials. Unlike traditional chiseling methods or basic angle grinders, these machines feature dual diamond-tipped blades that simultaneously cut parallel grooves at adjustable depths and widths. Professional contractors rely on concrete slotting machines to carve channels for electrical conduits, water pipes, communication cables, and other utility installations that need to be embedded within walls or floors. Modern concrete slotting machines incorporate powerful motors ranging from 2800W to 5500W, providing sufficient torque to cut through reinforced concrete, granite, marble, ceramic tiles, and brick walls. The adjustable cutting depth typically ranges from 15mm to 130mm depending on the model, while cutting width can be modified from 3mm to 42mm by adjusting blade spacing or quantity. These machines feature water-cooling systems that suppress dust generation during operation while simultaneously cooling the diamond blades to extend their operational lifespan. The ergonomic design includes adjustable handles that accommodate different cutting angles and user preferences, reducing operator fatigue during extended use. Safety features such as leakage protection, overload protection, and retractable blade guards ensure secure operation in demanding construction environments.

Key Technical Specifications That Define Performance

Professional-grade concrete slotting machines incorporate several critical specifications that determine their suitability for different construction applications. Motor power serves as the primary indicator of cutting capability, with 4000W to 5500W motors handling heavy-duty commercial projects involving reinforced concrete and thick masonry walls. Blade diameter directly influences maximum cutting depth, with common sizes ranging from 125mm to 350mm. Larger blade diameters enable deeper cuts in a single pass, improving efficiency on substantial infrastructure projects. The cutting speed measured in revolutions per minute affects both cutting efficiency and surface finish quality. Most professional concrete slotting machines operate between 5000 to 6500 RPM, balancing rapid material removal with precise control. Weight distribution significantly impacts operator comfort and cutting accuracy, with well-designed machines typically weighing between 6kg for handheld models to 95kg for heavy-duty stationary units. Voltage requirements vary by region, with 110V models common in North America and 220V versions standard in European and Asian markets. Professional contractors must select appropriate voltage specifications to ensure compatibility with available power sources on construction sites.

Primary Applications of Concrete Slotting Machines in Construction Projects

Construction professionals deploy concrete slotting machines across diverse building applications where precise channeling through hard materials proves essential. The most common application involves creating pathways for electrical wiring installations in both new construction and renovation projects. Electricians use concrete slotting machines to cut clean channels through concrete block walls, poured concrete surfaces, and masonry partitions to conceal electrical conduits, outlet boxes, and switch installations. This approach maintains clean wall aesthetics while meeting building codes that require concealed wiring in finished spaces. Plumbing installations represent another critical application where concrete slotting machines deliver substantial value. Plumbers utilize these tools to create channels for water supply lines, drainage pipes, and heating system conduits that must pass through concrete floors and walls. The precision cutting capability ensures pipes fit snugly within grooves, facilitating proper installation depth and alignment. HVAC contractors similarly rely on concrete slotting machines when installing climate control systems that require refrigerant lines and condensate drains to pass through concrete structural elements. The ability to cut precise channels at specific depths ensures proper insulation placement around these utility lines.

Decorative Concrete Applications and Surface Modifications

Beyond purely functional utility installations, concrete slotting machines serve decorative purposes in architectural concrete finishes. Designers and specialty contractors employ these machines to create geometric patterns, expansion joint details, and artistic relief features in polished concrete floors, pool decks, and architectural wall surfaces. The concrete slotting machine enables consistent depth and width control essential for achieving professional-looking decorative patterns that enhance visual appeal while maintaining structural integrity. Concrete restoration projects frequently require precise slot cutting for repair procedures. Restoration specialists use concrete slotting machines to remove damaged sections of concrete surfaces, create keying channels for new concrete pours, and prepare surfaces for structural reinforcement installations. The clean, controlled cuts produced by these machines minimize collateral damage to surrounding concrete, reducing the scope of repair work required. Bridge deck restoration, airport runway repairs, and industrial flooring rehabilitation all benefit from the precision capabilities that concrete slotting machines deliver.

Essential Uses for Concrete Slotting Machines in Utility Infrastructure

Utility companies and infrastructure contractors depend heavily on concrete slotting machines for installation and maintenance of underground utility networks. Municipal water departments utilize these machines when installing new water mains or repairing existing lines that pass beneath concrete roadways and sidewalks. The concrete slotting machine allows precise cutting of access channels without excavating entire road sections, minimizing disruption to traffic and reducing project costs. The ability to create narrow, controlled slots means less concrete removal and faster restoration of road surfaces after utility work completion. Telecommunications infrastructure installation represents a rapidly growing application for concrete slotting machines as fiber optic networks expand into urban areas. Communication contractors employ these tools to create pathways through concrete foundations, building walls, and underground cable trenches where data cables must pass. The precision offered by concrete slotting machines ensures cables achieve proper burial depth and protection from damage while maintaining building structural integrity. Electric utility companies similarly depend on these machines when installing underground power distribution systems, particularly in areas where overhead lines are being replaced with underground infrastructure for improved reliability and aesthetics.

Road Construction and Maintenance Operations

Highway construction and maintenance operations utilize concrete slotting machines for various pavement modification tasks. Road crews employ these tools to cut expansion joints in newly poured concrete highways, create drainage channels along roadway edges, and install rumble strips for driver safety. The concrete slotting machine delivers consistent depth control essential for expansion joints that accommodate thermal expansion without compromising pavement integrity. The high cutting speed enables road crews to complete joint cutting operations during narrow weather windows when concrete reaches optimal hardness for cutting. Airport runway maintenance teams rely on concrete slotting machines for precision cutting operations that must meet stringent aviation safety standards. Runway resurfacing projects require precise groove cutting to maintain proper surface texture coefficients that ensure adequate aircraft tire friction during takeoff and landing. The concrete slotting machine enables maintenance crews to create uniform groove patterns across extensive runway surfaces while maintaining operational efficiency. These machines also facilitate installation of runway lighting systems and drainage infrastructure that must be precisely embedded within concrete runway surfaces.

Advanced Features That Enhance Concrete Slotting Machine Performance

Professional concrete slotting machines incorporate advanced features that significantly improve operational efficiency and user safety. Water-cooled cutting systems represent one of the most valuable innovations, utilizing continuous water flow directed at the cutting zone to suppress dust generation and cool diamond blades. This dust suppression capability proves particularly important in occupied buildings where construction activities must minimize airborne particulate contamination. The water cooling simultaneously extends blade life by preventing thermal damage and reduces replacement costs over the machine's operational lifetime. Laser guidance systems integrated into modern concrete slotting machines dramatically improve cutting accuracy and reduce operator skill requirements. These systems project visible laser lines onto the work surface, providing clear visual references that guide blade positioning for straight cuts. The precision enabled by laser guidance proves especially valuable when installing utility conduits that must follow specific pathways or when creating decorative patterns requiring exact geometric alignment. Infrared positioning capabilities found on premium models allow operators to mark cutting paths in advance and follow predetermined routes with exceptional accuracy.

Ergonomic Design Elements for Operator Comfort

Ergonomic considerations play a critical role in concrete slotting machine design, particularly for tools used during extended periods. Adjustable handle systems enable operators to configure handle positions that optimize leverage and comfort based on cutting angle and personal preference. Vibration dampening systems incorporated into handle assemblies reduce transmitted vibration to operator hands and arms, decreasing fatigue and potential repetitive stress injuries during prolonged use. Balanced weight distribution ensures machines remain stable during operation without requiring excessive force to maintain control. Portable concrete slotting machines designed for handheld operation typically weigh between 6kg to 15kg, representing a careful balance between sufficient mass for stability and manageable weight for mobility. Heavier stationary models ranging from 50kg to 95kg provide superior stability for precision cutting operations but require alternative material handling approaches. Professional contractors select machine weight classes based on typical project requirements, with renovation specialists often preferring lighter portable units while infrastructure contractors opt for heavier-duty models. The power-to-weight ratio serves as a useful metric for evaluating machine efficiency, with higher ratios indicating more cutting power relative to operator burden.

Selecting the Right Concrete Slotting Machine for Specific Projects

Choosing an appropriate concrete slotting machine requires careful evaluation of project requirements, material characteristics, and operational constraints. Motor power represents the primary selection criterion, with larger motors necessary for cutting reinforced concrete, natural stone, and other particularly hard materials. Projects involving standard concrete blocks, brick, or ceramic tiles may be adequately served by 2800W to 4000W machines, while heavy infrastructure work demands 5000W to 5500W models. Contractors should consider the hardest materials they regularly encounter and select machines with sufficient power reserves to handle these challenging applications. Cutting depth requirements directly influence blade size selection and machine configuration. Shallow cuts up to 40mm depth for residential electrical installations can be achieved with compact handheld concrete slotting machines, while deeper utility trenches or structural modifications may require larger stationary models capable of 100mm to 130mm cutting depths. Some projects necessitate adjustable depth capabilities to accommodate varying installation requirements, making machines with incremental depth adjustment systems particularly valuable. The maximum cutting width similarly affects machine selection, with single-conduit installations requiring only narrow 3mm to 15mm slots while broader channels for multiple utilities demand machines capable of 30mm to 42mm cutting widths.

Quality Certifications and Compliance Standards

Professional construction operations require concrete slotting machines that comply with international quality and safety standards. ISO 9001 certification indicates manufacturers maintain quality management systems ensuring consistent production standards and reliable product performance. CE certification demonstrates compliance with European safety, health, and environmental protection standards, providing assurance that machines meet rigorous safety requirements. ROHS compliance confirms products contain no hazardous substances that could pose environmental or health risks during operation or disposal. Electrical safety certifications specific to the machine's intended market prove essential for legal operation and insurance compliance. North American markets require UL or CSA certification, while European markets mandate CE marking. Professional contractors should verify that concrete slotting machines carry appropriate certifications for their operational jurisdiction to avoid liability issues and ensure worker safety. Warranty terms and after-sales support availability similarly influence purchasing decisions, with reputable manufacturers typically offering comprehensive warranties and accessible technical support networks.

Conclusion

The concrete slotting machine delivers unmatched efficiency for creating precise channels in concrete and masonry surfaces across construction and utility applications. From electrical conduit installations to decorative concrete finishes, these specialized tools transform challenging manual processes into rapid, accurate cutting operations. Professional contractors recognize the concrete slotting machine as an essential investment that improves project quality while reducing labor costs and completion timelines.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

Foshan Lifa Building Materials Co., Ltd. stands as a trusted China concrete slotting machine manufacturer offering High Quality concrete slotting machine solutions to construction professionals worldwide. As a leading China concrete slotting machine supplier and China concrete slotting machine factory, we maintain extensive inventory for immediate shipment, ensuring your projects remain on schedule. Our competitive concrete slotting machine price positions combined with flexible OEM/ODM support make us the preferred China concrete slotting machine wholesale partner for distributors and contractors seeking reliable equipment. Each concrete slotting machine for sale undergoes rigorous quality control and ships with complete ISO 9001, CE, and ROHS certifications in secure packaging that ensures safe transit to your location.

Our experienced team combines deep expertise in R&D design, international quality certification, and global supply chain management to deliver superior products backed by exceptional customer service. With products successfully serving over 30 countries across South America, the EU, Australia, the Middle East, and Southeast Asia, we understand diverse market requirements and provide tailored solutions that meet local standards. Contact us at wz@jiancaiqy.com to discuss your concrete slotting machine requirements and discover how our mature R&D team, GMP factory capabilities, and cost advantages create value for your construction operations. Save this information for easy reference when your projects demand professional-grade cutting equipment.

References

1. Concrete Construction Editorial Staff. "Modern Tools for Concrete Cutting and Grooving Applications." Concrete Construction Magazine, American Concrete Institute.

2. Patterson, Richard M. and Williams, Jennifer L. "Power Tools in Construction: Safety, Efficiency, and Best Practices." Construction Safety Research Institute.

3. National Electrical Contractors Association. "Electrical Installation Standards for Concrete and Masonry Structures." NECA Technical Manual Series.

4. Thompson, David R. "Infrastructure Maintenance Equipment: Selection and Operation Guidelines." International Association of Public Works Officials.

5. Chen, Wei and Rodriguez, Maria. "Diamond Tool Technology for Construction Applications: Performance and Durability Factors." Construction Equipment Research Foundation.

Learn about our latest products and discounts through SMS or email