- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

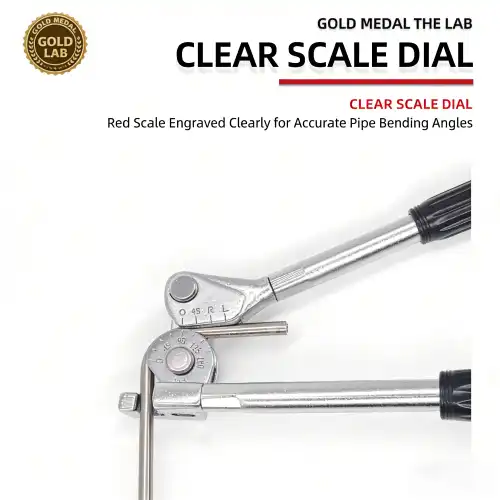

How a Hand Tube Bender Manual Improves Tube Bending Accuracy?

Picture this: You're halfway through an HVAC installation project, and suddenly you realize your tube bends are inconsistent—some angles are off by several degrees, tubes are kinked, and worst of all, you're wasting expensive materials with every failed attempt. This frustrating scenario happens far too often when professionals and DIY enthusiasts try to bend tubing without proper guidance. A hand tube bender manual transforms this chaotic process into a precise, repeatable operation by providing step-by-step instructions, adjustment calculations, and marking techniques that eliminate guesswork. When you follow a comprehensive hand tube bender manual, you gain access to proven methodologies that professional fabricators rely on daily to achieve consistent, accurate bends across various applications—from automotive brake lines to industrial piping systems.

Understanding the Role of a Hand Tube Bender Manual in Precision Work

The foundation of accurate tube bending begins with understanding what a hand tube bender manual actually provides. Far more than just basic operating instructions, a quality manual serves as your technical reference guide throughout the entire bending process. Professional-grade manuals include detailed specifications about tube diameter compatibility, bend radius calculations, material springback compensation, and gain adjustments that account for the difference between measured and actual bend lengths. When working with a hand tube bender manual, you'll discover that precision comes from following systematic procedures rather than relying on estimation. The manual teaches you how to properly mark your tubing using the correct reference points, ensuring that every bend starts exactly where intended. This marking technique alone can improve accuracy by eliminating the common mistake of misaligning the tube in the bender groove. Professional manuals provide comprehensive tables showing fractional adjustments based on bend angles and tube outside diameters—critical information that prevents cumulative errors in multi-bend configurations. The technical depth found in a proper hand tube bender manual addresses material-specific considerations that dramatically affect outcomes. For instance, stainless steel exhibits different springback characteristics compared to aluminum or copper, requiring adjusted bending angles to achieve the desired final result. Without this knowledge documented in your manual, you would need years of trial-and-error experience to develop the same level of proficiency. The manual essentially transfers decades of engineering knowledge directly to your workbench, enabling consistent results from your very first project.

Key Components Explained in Hand Tube Bender Manuals

Every comprehensive hand tube bender manual dedicates significant space to explaining the anatomy and function of the tool itself. Understanding these components is essential because precision bending requires knowing exactly how each part contributes to the process. The center mandrel or former maintains the tube's internal shape during bending, preventing collapse or distortion. The roller dies apply even pressure as they travel along the tube's exterior surface, minimizing surface marring while supporting the tube wall structure. The tube latch mechanism secures your workpiece without crushing it, maintaining proper positioning throughout the bend cycle. The manual for your hand tube bender manual will detail how angle indicators work in conjunction with starting markers to achieve precise bend angles. These graduated scales aren't arbitrary—they're calibrated to the specific bend radius of your tool. When you align your reference mark with the "L" indicator for a ninety-degree bend, you're utilizing geometry that's been mathematically calculated to account for the tool's unique specifications. This explains why different bender models require different marking alignments even when creating identical bend angles. Handle mechanics receive thorough coverage in quality manuals because proper leverage application directly impacts bend quality. The long handle provides mechanical advantage for applying consistent force throughout the bending arc, while the short handle controls the rate of bend application. Your hand tube bender manual will specify whether both handles require simultaneous pressure or if securing the tool in a vise allows single-handed operation. This seemingly minor detail significantly affects both accuracy and operator fatigue during extended fabrication sessions.

Practical Applications of Manual Guidance for Improved Accuracy

Translating manual instructions into real-world results requires understanding the practical application of documented techniques. A hand tube bender manual typically includes detailed case studies or example projects that demonstrate proper procedure sequencing. These examples show you how to measure from the correct reference points, calculate intermediate bend positions, and verify alignment before committing to each bend. Following these documented workflows eliminates common errors that occur when operators skip critical verification steps. One of the most valuable practical applications covered in hand tube bender manual documentation involves reverse bend techniques. These complex configurations require the tube to bend back upon itself, creating parallel or offset sections. The manual provides specific alignment instructions for positioning your reference mark to the right or left of the tube fixer depending on the desired direction. Without this guidance, achieving symmetrical reverse bends becomes nearly impossible, resulting in twisted or misaligned tube runs that fail pressure tests or don't fit properly during assembly. Multi-plane bending presents another challenge where manual guidance proves invaluable. When your project requires bends in different orientational planes, maintaining proper alignment between successive bends becomes critical. Professional hand tube bender manual instructions teach you to use spirit levels or sight down the tool's handles to verify that each new bend maintains the correct relationship with previous bends. This systematic approach to alignment checking prevents the accumulating angular errors that plague complex tube routing applications in automotive, aerospace, and industrial installations.

Material-Specific Techniques for Different Applications

Your hand tube bender manual should provide material-specific bending parameters that acknowledge the diverse properties of metals used in tube fabrication. Soft copper tubing commonly found in plumbing and refrigeration systems requires minimal force and exhibits negligible springback, allowing bends to closely match tool settings. In contrast, stainless steel tubing used in sanitary process systems or high-pressure applications demands significantly more bending force and demonstrates pronounced springback that must be compensated by overbending the initial angle. High-strength alloy steel tubes, like those constructed from the thickened ductile iron used in premium hand tube bender manual tools, present unique challenges addressed in advanced manual sections. These materials offer exceptional longevity and maintain dimensional stability under repeated bending stress, but require understanding work-hardening characteristics. The manual explains how to recognize when material properties have changed due to cold working and provides guidance on when annealing may be necessary for complex multi-bend configurations. Aluminum tubing occupies a middle ground in terms of bending characteristics, making it popular for custom fabrication work in recreational vehicle construction, furniture manufacturing, and prototype development. A thorough hand tube bender manual will note that aluminum's relatively low elastic modulus means bends can be achieved with moderate force, but the material's tendency toward surface galling requires using roller dies with smooth finishes. Some manufacturers even recommend specialized acetal inserts when working extensively with aluminum to prevent cosmetic damage that could compromise corrosion resistance in outdoor applications.

Advanced Accuracy Techniques from Professional Manuals

Professional-grade hand tube bender manual documentation goes beyond basic operation to address advanced techniques that separate adequate results from truly precision work. Gain calculation represents one such advanced concept that dramatically improves multi-bend accuracy. When tubing follows a radiused bend rather than a sharp angle, the actual material length consumed is less than what simple geometric calculation would suggest. Your manual provides tables or formulas showing exactly how much to reduce subsequent measurements based on the bend angle and tube diameter, preventing accumulating length errors in complex tube assemblies. Springback compensation requires equally sophisticated understanding documented in comprehensive manuals. Different materials, wall thicknesses, and bend radii all affect how much a tube will "spring back" toward its original straight configuration after bending force is released. Professional hand tube bender manual resources include material-specific springback factors, allowing you to intentionally overbend by a calculated amount. For example, stainless steel might require overbending by five to seven degrees to achieve a final ninety-degree bend after springback, while softer materials need minimal compensation. Temperature effects on bending accuracy receive attention in advanced manual sections because ambient conditions influence material properties. Cold temperatures increase material hardness and change springback characteristics, while elevated temperatures from repeated bending cycles can temporarily soften the work area. Professional fabricators consult their hand tube bender manual guidance on working temperature ranges and may employ temperature monitoring when precision tolerances are critical. Some applications even specify pre-heating procedures for extremely hard materials or thick-walled tubing where cold bending would risk fracture or excessive tool wear.

Troubleshooting Common Accuracy Problems

Even with careful attention to manual instructions, operators occasionally encounter accuracy problems that require systematic troubleshooting. A comprehensive hand tube bender manual includes dedicated troubleshooting sections that correlate symptoms with root causes. Oval or flattened tube cross-sections typically indicate insufficient internal support during bending—either the wrong size mandrel or improper tube seating in the bender groove. Wrinkling on the inner radius of bends points to excessive compression that occurs when bend radii are too tight for the tube diameter and wall thickness combination. Inconsistent bend angles across multiple pieces often trace back to improper marking techniques or failure to account for gain in successive bend positions. Your hand tube bender manual will emphasize the importance of measuring from bend centerlines rather than tube ends when laying out complex configurations. This seemingly subtle distinction prevents cumulative errors from propagating through multi-bend assemblies. Professional operators develop marking protocols based on manual guidance that they apply consistently across all projects, ensuring repeatability even when switching between different tube sizes or materials. Surface damage including scoring, marring, or roller marks indicates problems with tool condition or lubrication practices. Quality hand tube bender manual documentation specifies proper maintenance procedures including periodic cleaning of roller dies, inspection of groove surfaces for contamination or damage, and appropriate lubricant selection for different materials. The manual for tools constructed with durable finishes like fine baking paint resistant to acid, alkali, and oil will note that these protective coatings require specific cleaning agents to avoid degradation that could transfer to tube surfaces during bending operations.

Integrating Manual Knowledge with Quality Tooling

The most accurate bending results emerge from the synergy between comprehensive hand tube bender manual guidance and quality tool construction. Professional-grade benders manufactured from materials like thickened ductile iron provide the dimensional stability necessary to achieve the precision that manual instructions promise. When your tool maintains consistent geometry across thousands of bending cycles, the techniques and measurements documented in the manual remain valid indefinitely. Conversely, tools that flex or wear rapidly force operators to constantly adjust their approach, rendering manual guidance less effective over time. Modern hand tube bender manual tools incorporate design features specifically intended to prevent common accuracy problems. The simple design philosophy that prevents pipe breakage from excessive force directly supports precision work by ensuring operators can feel appropriate resistance throughout the bend cycle. This tactile feedback, combined with manual instruction on proper force application, helps develop the muscle memory that characterizes expert tube bending technique. Tools with capacity ranging from one-quarter inch to one inch outside diameter and bend angles up to one hundred eighty degrees provide the versatility to handle diverse projects without switching equipment—consistency that reinforces the systematic approaches taught in quality manuals. Weight distribution and dimensional specifications also impact how effectively manual techniques translate to real-world results. A tool weighing approximately five and a half pounds with dimensions of eighteen inches by six inches by four inches offers sufficient mass for stability during bending operations while remaining portable enough for field work. Your hand tube bender manual should address proper tool support methods including vise mounting or freestanding operation, explaining how each approach affects leverage application and bend consistency. Professional fabricators often maintain both mounting options, selecting based on project requirements and workspace constraints as their manual recommends.

Certification and Quality Standards in Manual Documentation

Comprehensive hand tube bender manual resources reference relevant quality standards and certifications that validate both tool construction and bending techniques. Products manufactured in accordance with ISO9001 quality management systems undergo documented procedures ensuring consistency across production runs. When your manual references these standards, you gain confidence that the tool specifications and capabilities described accurately reflect the equipment you're operating. This alignment between documentation and physical tool characteristics is essential for achieving the precision that professional applications demand. International standards such as ASTM specifications for metal tubing and DIN standards for mechanical components provide the framework within which hand tube bender manual instructions operate. Understanding these standards helps operators recognize when their work must meet specific industry requirements versus applications where broader tolerances are acceptable. For instance, tube bending for hydraulic systems operating at several thousand PSI requires far tighter tolerances than decorative metalwork or furniture fabrication. Your manual should clarify which techniques and verification procedures apply to different quality tiers. The presence of full certifications and compliance documentation supporting your hand tube bender manual indicates manufacturer commitment to quality that extends beyond the tool itself to comprehensive customer support. Companies providing detailed technical manuals typically also offer responsive customer service, replacement parts availability, and ongoing technical guidance as products and applications evolve. This long-term support relationship enables operators to continuously improve their bending accuracy by accessing updated techniques, troubleshooting assistance, and application-specific guidance that goes beyond what any printed manual can provide.

Conclusion

A comprehensive hand tube bender manual fundamentally transforms tube bending from uncertain guesswork into a precise, repeatable craft. By providing detailed instructions on tool operation, material-specific techniques, gain calculations, springback compensation, and systematic troubleshooting, quality manuals enable both professionals and enthusiasts to achieve consistent, accurate results that meet exacting standards across diverse applications from HVAC installations to custom fabrication projects.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

When precision tube bending is critical to your projects, partnering with a reliable supplier makes all the difference. Foshan Lifa Building Materials Co., Ltd. stands as your trusted China hand tube bender manual manufacturer, offering professional-grade tools backed by comprehensive documentation and expert support. As a leading China hand tube bender manual supplier, we serve over thirty countries with ISO9001-compliant products featuring thickened ductile iron construction and durable finishes. Our experienced team provides flexible OEM/ODM customization to meet your specific requirements. Whether you need High Quality hand tube bender manual tools for your business or competitive hand tube bender manual wholesale pricing, our China hand tube bender manual factory delivers exceptional value. Explore our hand tube bender manual for sale options with reliable hand tube bender manual price structures that fit your budget. Contact us today at wz@jiancaiqy.com to discuss how our expertise in R&D, quality control, and global logistics can support your tube bending applications with tools and guidance that deliver consistent accuracy every time.

References

1. "Hand Tube Bender Operating Manual" by Swagelok Company, Technical Documentation Division

2. "Precision Tube Bending: Techniques and Best Practices" by Manufacturing Engineering Society, Industrial Fabrication Standards Committee

3. "Material Properties and Springback Compensation in Cold Tube Bending" by Dr. James Richardson, Journal of Materials Processing Technology

4. "Quality Assurance in Tube Fabrication Systems" by International Standards Organization, ISO Technical Committee 164

5. "Advanced Techniques for Manual Tube Bending Operations" by National Tooling and Machining Association, Professional Training Division

Learn about our latest products and discounts through SMS or email