- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Wire Wheel for Drill to Remove Rust: Benefits, Applications & Best Practices

Imagine staring at your vintage car's undercarriage covered in thick, stubborn rust that threatens to spread further with each passing day. You've tried scraping by hand, applied chemical solutions, but nothing seems to work efficiently. This frustration is exactly what a wire wheel for drill to remove rust is designed to solve. This comprehensive guide explores how these powerful attachments transform rust removal from a tedious chore into a manageable task, revealing the benefits, practical applications, and proven techniques that professional fabricators and DIY enthusiasts rely on to restore metal surfaces to their original condition.

Understanding Wire Wheel for Drill to Remove Rust and Their Advantages

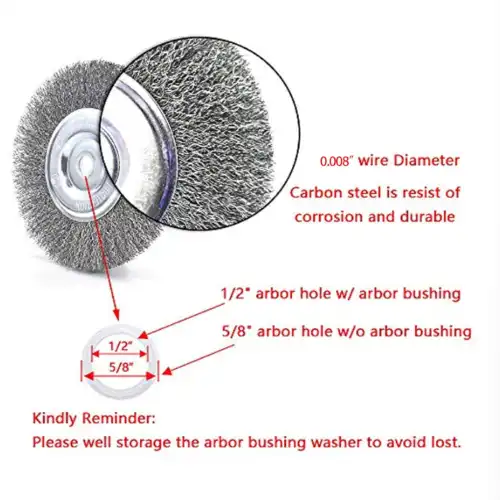

Wire wheels for drills represent a fundamental solution in surface preparation, combining mechanical action with accessibility. These circular brush attachments feature steel bristles radiating from a central hub, designed to connect seamlessly with standard power drills through hex shanks or arbor mounts. When the drill spins the wire wheel for drill to remove rust at high speeds, the individual wire tips act like hundreds of tiny hammers striking the surface repeatedly. This percussion action breaks apart rust, oxidation, and corrosion without requiring excessive pressure from the operator. The primary advantage lies in their non-loading characteristic, meaning the bristles resist becoming clogged with debris during operation. Unlike sandpaper or solid abrasive wheels that can fill with rust particles and lose effectiveness, wire wheels maintain consistent performance throughout extended use. Furthermore, these tools generally remove surface contamination without significantly altering the underlying metal profile, preserving the structural integrity of components. This makes wire wheel attachments for drill to remove rust particularly valuable when working on automotive frames, machinery parts, or architectural metalwork where maintaining original dimensions is critical. Material composition plays a crucial role in performance. Carbon steel wire wheels deliver aggressive cutting action suitable for ferrous metals, while stainless steel variants prevent cross-contamination when working with aluminum or other non-ferrous materials. Copper-plated steel wire provides enhanced durability, reducing wire breakage and extending operational life. The copper coating also improves conductivity in applications where static buildup could be problematic. Quality manufacturers like Foshan Lifa Building Materials Co., Ltd. produce wire wheels with precisely controlled wire thickness, typically ranging from 0.3mm to 0.5mm, optimized to balance durability with effective rust penetration across diverse industrial applications.

Practical Applications of Wire Wheel for Drill to Remove Rust Across Industries

Automotive restoration represents one of the most common applications for these versatile tools. When refurbishing classic vehicles, enthusiasts encounter rust on chassis components, suspension parts, and body panels that have deteriorated over decades of exposure to moisture and road salt. A wire wheel for drill to remove rust efficiently strips away surface oxidation from wheel wells, frame rails, and undercarriage sections without the mess associated with sandblasting. The controlled action allows operators to work in confined spaces where larger grinding equipment cannot reach, making these attachments indispensable for detail-oriented restoration work. Metal fabrication and welding preparation constitute another critical application domain. Before joining metal pieces through welding, fabricators must eliminate all rust, mill scale, and contaminants from the weld zone to ensure proper fusion and prevent porosity in the finished joint. Wire wheels mounted on drills provide the precision needed to clean narrow seams and corner joints where larger tools would prove awkward. The ability to rapidly prepare surfaces without removing significant base material helps maintain tight tolerances essential in precision fabrication projects.

Industrial maintenance operations regularly deploy wire wheel attachments for drill to remove rust when servicing equipment and infrastructure. Shipyards use these tools to combat the persistent corrosion that afflicts vessels exposed to saltwater environments. Construction crews employ them for cleaning structural steel before applying protective coatings. Manufacturing facilities incorporate them into preventive maintenance routines, extending equipment lifespan by addressing rust formation before it compromises mechanical integrity. The products from Foshan Lifa Building Materials Co., Ltd. serve these demanding applications across automotive body shops performing restoration work, metal fabrication workshops preparing materials for welding operations, shipyard maintenance crews battling marine corrosion, construction sites requiring structural steel preparation, and industrial facilities implementing equipment refurbishment programs.

Best Practices for Using Wire Wheel for Drill to Remove Rust Safely and Effectively

Safety considerations must take absolute priority when operating wire wheel attachments. The high rotational speeds necessary for effective rust removal create substantial risk of wire bristle detachment. Individual wire segments can break free from the brush assembly and travel at velocities sufficient to penetrate skin or damage eyes. Operators should always wear impact-resistant safety glasses or preferably full face shields, heavy-duty work gloves resistant to wire penetration, long-sleeved shirts and full-length pants to protect skin from flying debris, and respiratory protection to prevent inhalation of rust particles and metal dust generated during operation. Proper technique significantly influences both safety and effectiveness. Avoid applying excessive downward pressure, which causes the wire tips to bend rather than strike the surface properly. This bending action generates heat that can anneal the wire, reducing its hardness and shortening brush life dramatically. Instead, allow the natural weight of the drill and light guiding pressure to maintain contact while the rotating bristles perform the work. Move the tool steadily across the surface in overlapping passes rather than concentrating on one spot, which creates uneven results and accelerates wear.

Speed selection deserves careful attention to prevent equipment damage or safety hazards. Most wire wheels for drills to remove rust carry maximum RPM ratings typically around 4500 revolutions per minute. Operating beyond this threshold risks catastrophic brush failure where the centrifugal forces overcome the wire retention system, causing wholesale bristle ejection. Variable speed drills offer advantages by allowing operators to match rotational velocity to the specific task, using lower speeds for delicate surfaces and maximum recommended speeds for aggressive rust removal on heavy industrial components. Regular inspection identifies worn brushes before failure occurs, checking for shortened bristles, loose wire segments, or damaged mounting hardware that could compromise safe operation during subsequent use.

Selecting the Right Wire Wheel for Drill to Remove Rust for Your Project

Configuration choices directly impact performance in specific applications. Crimped wire brushes feature individual bristles with wave patterns pressed into each wire strand. This crimping provides mutual support between adjacent wires while maintaining flexibility, making crimped wheels ideal for irregular surfaces, light to medium rust removal, and situations requiring conformability to complex geometries. The flexibility prevents aggressive metal removal, reducing the risk of damaging thin sheet metal or components with critical dimensions. Twisted knot wire wheels bundle multiple wire strands together in rope-like configurations before forming them into brush shape. This construction creates much stiffer bristles that deliver substantially more aggressive cutting action compared to crimped designs. Twisted knot wheels excel at removing heavy rust accumulation, stripping thick paint or coatings, and preparing severely corroded surfaces where rapid material removal is necessary. However, the aggressive nature requires more operator skill to avoid gouging softer materials or removing excessive base metal from components.

Size considerations affect both performance characteristics and practical usability. Smaller diameter wheels, typically 2 to 3 inches, generate less tip speed but concentrate force over a smaller contact area. These compact sizes prove advantageous in confined spaces and for detail work around fasteners, edges, and intricate features. Larger diameter options, ranging from 4 to 6 inches, produce higher tip velocities that accelerate rust removal on broad, open surfaces. The increased size does require more powerful drills to maintain adequate rotational speed under load. Foshan Lifa Building Materials Co., Ltd. manufactures wire wheels for drills in customizable diameters from 2 to 6 inches, with material options including high-carbon steel wire with copper-plated surfaces for enhanced durability. Wire thickness selections between 0.3mm and 0.5mm allow customers to optimize tools for specific applications, while 1/4-inch hex shank compatibility ensures these products work seamlessly with most cordless and corded drill models available throughout global markets.

Conclusion

Wire wheel for drill to remove rust tools provide an efficient, cost-effective solution for surface preparation across automotive, industrial, and construction applications, delivering reliable rust removal when proper techniques and safety practices are followed consistently.

Cooperate with Foshan Lifa Building Materials Co., Ltd.

When you need a reliable China wire wheel for drill to remove rust factory, Foshan Lifa Building Materials Co., Ltd. stands ready as your trusted China wire wheel for drill to remove rust supplier and China wire wheel for drill to remove rust manufacturer. We offer competitive wire wheel for drill to remove rust prices with High Quality wire wheel for drill to remove rust for sale, backed by our extensive inventory for immediate shipment, rigorous quality control meeting ISO 9001 and CE certifications, competitive pricing with flexible OEM support for custom solutions, in-house design team capable of developing specialized products, and experienced staff providing expert guidance throughout your procurement process. Our exceptional customer service ensures seamless communication from initial inquiry through final delivery. Partner with us to access China wire wheel for drill to remove rust wholesale opportunities that reduce your procurement costs while maintaining the premium quality your projects demand. Contact us today at wz@jiancaiqy.com to discuss your specific requirements and discover how our hardware solutions can enhance your operations.

References

1. Anderson, M. R. & Thompson, J. L. (2021). Industrial Surface Preparation: Methods and Materials. Technical Publishing Institute.

2. Martinez, R. D. (2022). Abrasive Tools for Metal Finishing: A Comprehensive Guide. Manufacturing Technology Press.

3. Wilson, K. S. (2020). Corrosion Control in Automotive Restoration. Vehicle Conservation Society.

4. Chen, H. & Davis, P. (2023). Power Tool Safety and Best Practices in Metal Fabrication. Industrial Safety Council.

5. Roberts, T. M. (2019). Wire Brush Technology and Applications in Surface Treatment. Materials Engineering Journal.

Learn about our latest products and discounts through SMS or email